My Garage

My Account

Cart

Genuine Toyota Celica Fuse

Circuit Fuse- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

42 Fuses found

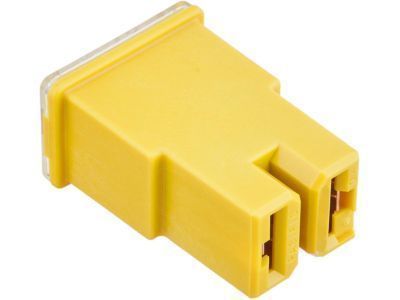

Toyota Celica Fusible Link

Part Number: 90982-08227$12.25 MSRP: $17.11You Save: $4.86 (29%)Ships in 1-3 Business DaysToyota Celica Engine Room Fusible Link

Part Number: 90982-08246$11.53 MSRP: $16.12You Save: $4.59 (29%)Ships in 1-3 Business DaysToyota Celica Fusible Link

Part Number: 90982-08190$15.34 MSRP: $21.44You Save: $6.10 (29%)Ships in 1-3 Business DaysToyota Celica Engine Room Fusible Link

Part Number: 90982-08203$11.53 MSRP: $16.12You Save: $4.59 (29%)Ships in 1-3 Business DaysToyota Celica Multi Fuse

Part Number: 90982-09014$5.70 MSRP: $7.96You Save: $2.26 (29%)Ships in 1-3 Business DaysToyota Celica Fuse Block

Part Number: 90982-09003$1.65 MSRP: $2.32You Save: $0.67 (29%)Ships in 1-2 Business DaysToyota Celica Fuse, Medium Current

Part Number: 90982-10001$4.75 MSRP: $6.63You Save: $1.88 (29%)Ships in 1-2 Business DaysToyota Celica Fuse, Fuse Block

Part Number: 90982-09009$2.13 MSRP: $2.98You Save: $0.85 (29%)Ships in 1-3 Business DaysToyota Celica Fusible Link

Part Number: 90982-08189$11.77 MSRP: $16.45You Save: $4.68 (29%)Ships in 1-3 Business DaysToyota Celica Engine Room Fusible Link

Part Number: 90982-08285$15.22 MSRP: $21.28You Save: $6.06 (29%)Ships in 1 Business DayToyota Celica Fusible Link

Part Number: 90982-08188$6.02 MSRP: $8.42You Save: $2.40 (29%)Ships in 1-3 Business DaysToyota Celica Fuse Block

Part Number: 90982-09010$2.13 MSRP: $2.98You Save: $0.85 (29%)Ships in 1-3 Business DaysToyota Celica Engine Room Fusible Link

Part Number: 90982-08283$13.20 MSRP: $18.45You Save: $5.25 (29%)Ships in 1-2 Business DaysToyota Celica Fuse, Mini

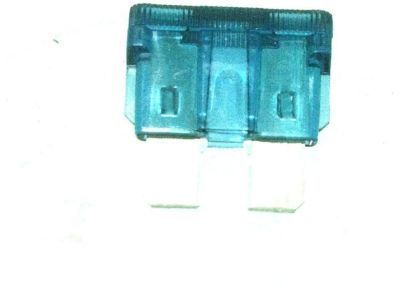

Part Number: 90982-09011$2.13 MSRP: $2.98You Save: $0.85 (29%)Ships in 1-3 Business DaysToyota Celica Fuse Block

Part Number: 90982-09002$1.18 MSRP: $1.64You Save: $0.46 (29%)Ships in 1-2 Business DaysToyota Celica Fuse Block 7.5A

Part Number: 90982-09008$2.13 MSRP: $2.98You Save: $0.85 (29%)Ships in 1-3 Business DaysToyota Celica Fuse, Fuse Block

Part Number: 90982-09004$1.18 MSRP: $1.64You Save: $0.46 (29%)Ships in 1-2 Business DaysToyota Celica Fuse Block

Part Number: 90982-09016$5.70 MSRP: $7.96You Save: $2.26 (29%)Ships in 1-3 Business DaysToyota Celica Fuse, Fuse Block

Part Number: 90982-09005$1.18 MSRP: $1.64You Save: $0.46 (29%)Ships in 1-2 Business DaysToyota Celica Fuse, Medium Current

Part Number: 90982-10002$3.68 MSRP: $5.14You Save: $1.46 (29%)Ships in 1-2 Business Days

| Page 1 of 3 |Next >

1-20 of 42 Results

Toyota Celica Fuse

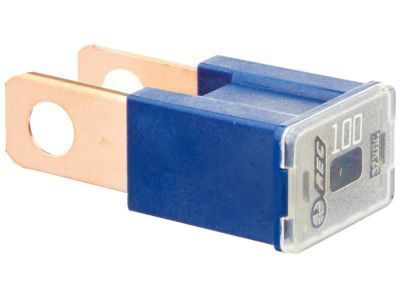

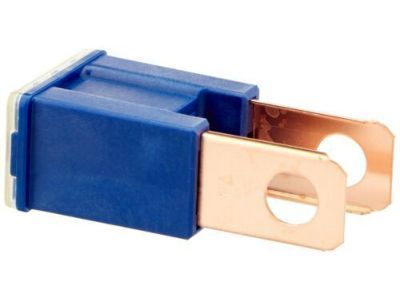

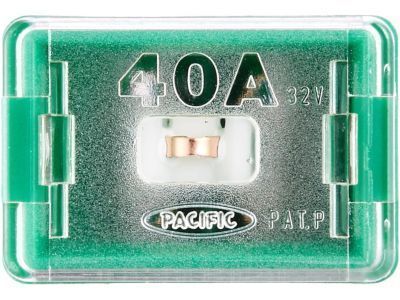

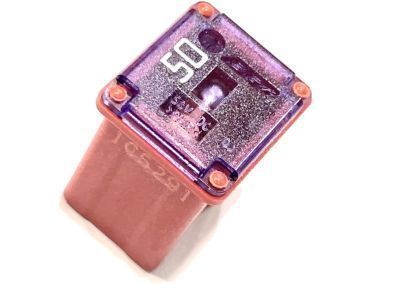

The Fuse in Toyota Celica vehicles operates as the primary safety apparatus to break electrical current when safe thresholds are exceeded. A metal wire inside the Fuse operates by disintegrating from high current levels causing power interruption to protect electrical components. A fusible assembly exists under the hood where different power distribution relays control electrical connections to key systems including radios and light functions. Different types of Fuse including blade Fuse and glass tube Fuse have been applied in Celica models since their production period. Blade Fuse dominate contemporary automotive markets since they exist in diverse dimensions and color codes which represent designated ampere capacity levels. Older North America vehicles use glass tube Toyota replacement units that keep a standard size across all units although they differ in amperage value. The distinctive features of these Toyota Celica replacement parts relate to their structural differences together with their adaptable use in modern automobiles.

If you are in demand for superior quality and affordable OEM Toyota Celica Fuse, then shop with us! We own a wide range of the reduced-priced genuine Toyota Celica Fuse. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Celica Fuse Parts Questions & Experts Answers

- Q: How are electrical circuits protected, and what steps should be taken if a fuse blows on Toyota Celica?A:The protection of electrical circuits of automobile utilizes fuses, circuit breakers and fusible links in which the fuse blocks are attached under the panel of instrument in two sides of the dashboard and in the engine section close to the battery and before the ABS actuator. Every fuse is assigned to a particular circuit this is written on the fuse box. Miniature fuses with a Blade Terminal structure allow removal and new installation with a simple movement with the fingertips. As a first troubleshooting step in the occurrence of electrical component failure, one should always check the fuse. Since the casing of a typical fuse is made of transparent plastic, it is relatively easy to check for the element's condition by simple visual assessment after a blown fuse. In this case, if the continuity test is needed, the tips of the blade terminal in the fuse body can be checked. All blown fuses should be replaced with like types as fuses of different capacities may look identical but should not be cross-connected; each circuit has the protection requirement that is specifically provided by the molded amperage value labeled on the fuse body. If a replacement fuse blows out as soon as it is installed, then it should not be replaced again until the root of the problem, usually a short circuit brought about a line fault; a broken or exhausted line is fixed.