My Garage

My Account

Cart

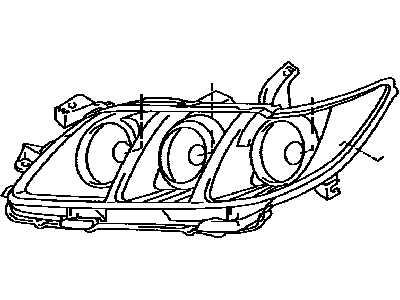

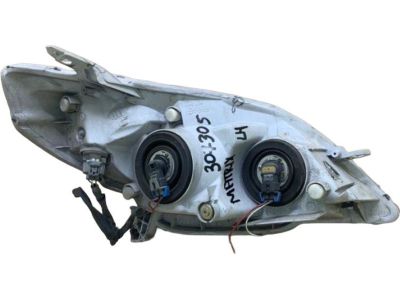

Genuine Toyota Matrix Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Headlights found

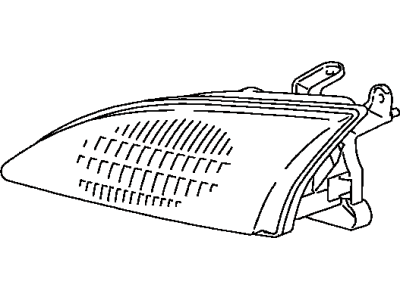

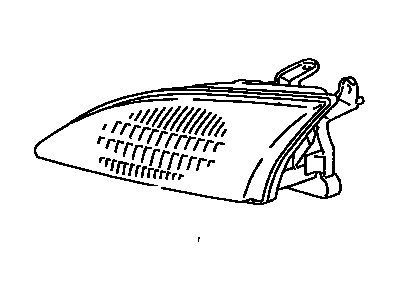

Toyota Matrix Passenger Side Headlight Unit Assembly

Part Number: 81130-02360$161.57 MSRP: $229.69You Save: $68.12 (30%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Unit Assembly

Part Number: 81170-02350$161.57 MSRP: $229.69You Save: $68.12 (30%)Ships in 1-3 Business DaysToyota Matrix Passenger Side Headlight Assembly

Part Number: 81110-02210$214.24 MSRP: $307.20You Save: $92.96 (31%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Assembly

Part Number: 81150-02350$216.44 MSRP: $310.37You Save: $93.93 (31%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Assembly

Part Number: 81150-02220$214.24 MSRP: $307.20You Save: $92.96 (31%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Unit Assembly

Part Number: 81170-02220$159.23 MSRP: $226.36You Save: $67.13 (30%)Toyota Matrix Passenger Side Headlight Assembly

Part Number: 81110-02360$216.44 MSRP: $310.37You Save: $93.93 (31%)Ships in 1-3 Business DaysToyota Matrix Passenger Side Headlight Unit Assembly

Part Number: 81130-02210$159.23 MSRP: $226.36You Save: $67.13 (30%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Unit Assembly

Part Number: 81170-02360$163.91 MSRP: $233.02You Save: $69.11 (30%)Ships in 1-2 Business DaysToyota Matrix Passenger Side Headlight Unit Assembly

Part Number: 81130-02370$163.91 MSRP: $233.02You Save: $69.11 (30%)Ships in 1-3 Business DaysToyota Matrix Right Hand Headlamp Assembly

Part Number: 81110-02650$199.51 MSRP: $286.08You Save: $86.57 (31%)Ships in 1-3 Business DaysToyota Matrix Drivers Headlight Headlamp Replacement

Part Number: 81150-02650$197.54 MSRP: $283.25You Save: $85.71 (31%)Ships in 1-3 Business DaysToyota Matrix Passenger Side Headlamp Assembly

Part Number: 81110-02370$219.69 MSRP: $315.02You Save: $95.33 (31%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Assembly Composite

Part Number: 81150-02360$219.69 MSRP: $315.02You Save: $95.33 (31%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Assembly

Part Number: 81150-02210$220.74 MSRP: $316.51You Save: $95.77 (31%)Ships in 1-3 Business DaysToyota Matrix Passenger Side Headlight Assembly

Part Number: 81110-02190$217.49 MSRP: $311.86You Save: $94.37 (31%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Unit Assembly

Part Number: 81170-02200$159.23 MSRP: $226.36You Save: $67.13 (30%)Ships in 1-3 Business DaysToyota Matrix Passenger Side Headlight Unit Assembly

Part Number: 81130-02190$159.23 MSRP: $226.36You Save: $67.13 (30%)Ships in 1-3 Business DaysToyota Matrix Passenger Side Headlight Unit Assembly

Part Number: 81130-02200$159.11 MSRP: $226.20You Save: $67.09 (30%)Ships in 1-3 Business DaysToyota Matrix Driver Side Headlight Assembly Composite

Part Number: 81150-02200$217.49 MSRP: $311.86You Save: $94.37 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 22 Results

Toyota Matrix Headlight

If you are in demand for superior quality and affordable OEM Toyota Matrix Headlight, then shop with us! We own a wide range of the reduced-priced genuine Toyota Matrix Headlight. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Matrix Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to ensure safety on Toyota Matrix?A:To make sure one does not blind fellow drivers on the road and also to ensure visibility on the road, the headlights have to be aimed well. The inspection can be done after a year or time that another headlight is fitted or front end body work is carried out. The following procedure gives a brief fix until one can get an expert to do the right alignment. Each housing of headlight has one or two adjustment screws in the vertical direction but no adjustment screw in the horizontal direction. Here, it is advised to make use of masking tape, a blank wall and a level floor in the process of adjusting the headlights. Place the tape vertically on that wall along the vehicle center line and the centerlines of the two headlight and place a horizontal tape along the centerlines of headlight when the car is backed a few inches off the wall. They should be made with the vehicle situated 25 feet from the wall, parked horizontally and having half tank of petrol and no load carrying. To make low beam adjustment, align the high intensity region two inches below the horizontal line. When the high beams are ON, make sure the high beam high-intensity zone is located vertically superimposed on the horizontal line. In case of compromise, consider preserving the low beams the most as they are utilized much more and determine security to a great extent. To do this ensure that the headlights have been adjusted by a dealer service department or by a service station as soon as possible.