My Garage

My Account

Cart

Genuine Toyota Matrix Variable Timing Sprocket

Timing Gear Sprocket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Variable Timing Sprockets found

Toyota Matrix Camshaft Gear Assembly

Part Number: 13050-0T050$259.25 MSRP: $371.75You Save: $112.50 (31%)Toyota Matrix Camshaft Gear

Part Number: 13523-0D010$43.66 MSRP: $61.03You Save: $17.37 (29%)Ships in 1-2 Business DaysToyota Matrix Camshaft Gear Assembly

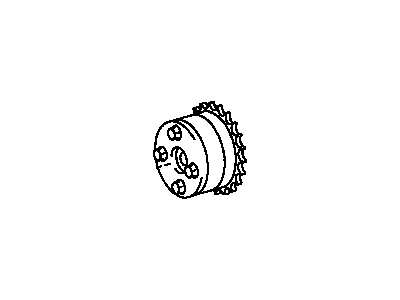

Part Number: 13070-0T011$300.78 MSRP: $431.30You Save: $130.52 (31%)Ships in 1-2 Business DaysToyota Matrix Camshaft Gear Assembly

Part Number: 13050-28021$259.25 MSRP: $371.75You Save: $112.50 (31%)Ships in 1 Business DayToyota Matrix Camshaft Gear Assembly

Part Number: 13050-0T011$259.25 MSRP: $371.75You Save: $112.50 (31%)Ships in 1-2 Business DaysToyota Matrix Sprocket, Camshaft Timing

Part Number: 13523-22020$43.66 MSRP: $61.03You Save: $17.37 (29%)Ships in 1-2 Business DaysToyota Matrix Gear Assembly, Camshaft Timing

Part Number: 13050-0T010$259.25 MSRP: $371.75You Save: $112.50 (31%)Toyota Matrix Gear Assy, Camshaft Timing Exhaust

Part Number: 13070-37010$300.78 MSRP: $431.30You Save: $130.52 (31%)Ships in 1-3 Business DaysToyota Matrix Gear Assembly, Camshaft Timing

Part Number: 13050-37012$278.97 MSRP: $400.02You Save: $121.05 (31%)Toyota Matrix Gear Assembly, Camshaft Timing

Part Number: 13050-22011$285.23 MSRP: $409.01You Save: $123.78 (31%)Toyota Matrix Camshaft Timing Gear Assembly

Part Number: 13050-22012$285.23 MSRP: $409.01You Save: $123.78 (31%)Ships in 1-3 Business DaysToyota Matrix Gear Assy, Camshaft Timing Exhaust

Part Number: 13070-0T010$300.78 MSRP: $431.30You Save: $130.52 (31%)Ships in 1-3 Business DaysToyota Matrix Gear Assembly, Camshaft Timing

Part Number: 13050-0D020$285.23 MSRP: $409.01You Save: $123.78 (31%)Ships in 1-3 Business DaysToyota Matrix Gear Assembly, Camshaft

Part Number: 13050-0H010$259.25 MSRP: $371.75You Save: $112.50 (31%)Ships in 1-2 Business DaysToyota Matrix Camshaft Gear Assembly

Part Number: 13050-37060$268.59 MSRP: $385.13You Save: $116.54 (31%)Ships in 1-3 Business DaysToyota Matrix Camshaft Gear Assembly

Part Number: 13050-37030$286.97 MSRP: $411.50You Save: $124.53 (31%)Ships in 1-3 Business Days

Toyota Matrix Variable Timing Sprocket

If you are in demand for superior quality and affordable OEM Toyota Matrix Variable Timing Sprocket, then shop with us! We own a wide range of the reduced-priced genuine Toyota Matrix Variable Timing Sprocket. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Matrix Variable Timing Sprocket Parts Questions & Experts Answers

- Q: How to Check the Spool Valve and Variable Timing Sprocket on a Toyota Matrix?A:The VVT system used in all models include an intake Camshaft timing that is controlled by oil pressure to either advance or retard the intake camshaft sprocket/actuator assembly for improvement of the engine power output, fuel economy, and reduction of emissions where these conditions prevail. They include the PCM, VVT oil control valve, the filter for the VVT oil control valve and the intake camshaft sprocket/actuator. Using a number of sensors, the PCM decides the oil control Valve to regulate the pressure of the oil to the actuator assembly. The actuator hydraulically driven contains an inner hub equipped with the fixed vanes and through the oil pressure the rotation of the camshaft is performed related to the adjustment through which the camshaft can be in advance to 21 degrees, or in case necessary-to be in a neutral state. Dependent on the load on the engine, the system can control the cam shaft timing in order to provide the right combustion. Especially, VVT oil control valve and the filter should be frequently maintained due to most problems root cause from them. To diagnose, the strainer of the oil control valve filter should be free from blockage, the valve's resistance would then be evaluated; if this has exceeded the allowable limit then it must be replaced. The second examination entails observing the movement of the plunger of the oil control valve every time voltage is supplied. As for the camshaft sprocket/actuator assembly, the valve cover and the camshaft have to be taken off; the actuator is then cleaned and it has to be installed correctly with the functionality as well. It is recommended to test the rotation of the actuator using air pressure and if it fails to do so, one must replace the assembly. Disassembly is the process of taking apart the equipment while reassembly is done systematically in a backward way to the process of disassembly.

Related Toyota Matrix Parts

Browse by Year

2014 Variable Timing Sprocket 2013 Variable Timing Sprocket 2012 Variable Timing Sprocket 2011 Variable Timing Sprocket 2010 Variable Timing Sprocket 2009 Variable Timing Sprocket 2008 Variable Timing Sprocket 2007 Variable Timing Sprocket 2006 Variable Timing Sprocket 2005 Variable Timing Sprocket 2004 Variable Timing Sprocket 2003 Variable Timing Sprocket