My Garage

My Account

Cart

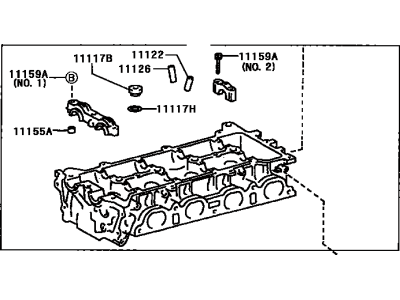

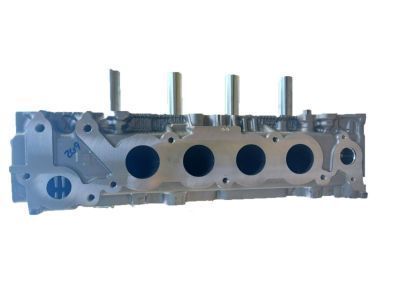

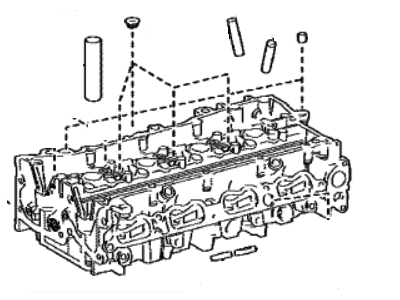

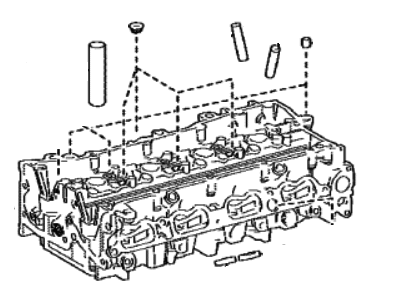

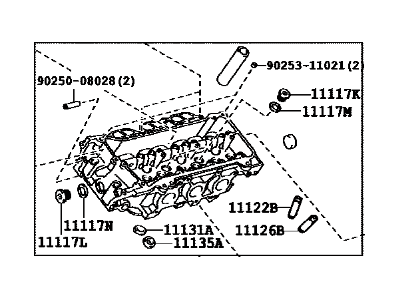

Genuine Toyota RAV4 Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Cylinder Heads found

Toyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-28012$686.10 MSRP: $871.23You Save: $185.13 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-29625$913.58 MSRP: $1160.10You Save: $246.52 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-28011$686.10 MSRP: $871.23You Save: $185.13 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-39776$907.45 MSRP: $1152.32You Save: $244.87 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-39715$907.45 MSRP: $1152.32You Save: $244.87 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-29627$854.87 MSRP: $1085.55You Save: $230.68 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-09346$907.45 MSRP: $1152.32You Save: $244.87 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-F9002$850.53 MSRP: $1080.04You Save: $229.51 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-0H011$686.10 MSRP: $871.23You Save: $185.13 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-09345$907.45 MSRP: $1152.32You Save: $244.87 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-28010$706.97 MSRP: $897.73You Save: $190.76 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-09451$792.60 MSRP: $1006.48You Save: $213.88 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-39536$1212.99 MSRP: $1540.30You Save: $327.31 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-79225$1005.85 MSRP: $1277.28You Save: $271.43 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11102-09141$1211.64 MSRP: $1538.58You Save: $326.94 (22%)Ships in 1-3 Business DaysToyota RAV4 Head Sub-Assembly, Cylinder, Driver Side

Part Number: 11102-39055$1211.64 MSRP: $1538.58You Save: $326.94 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11102-39056$1211.64 MSRP: $1538.58You Save: $326.94 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head Sub-Assembly

Part Number: 11101-09261$1212.99 MSRP: $1540.30You Save: $327.31 (22%)Ships in 1-3 Business DaysToyota RAV4 Cylinder Head

Part Number: 11101-F9001$913.58 MSRP: $1160.10You Save: $246.52 (22%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 31 Results

Toyota RAV4 Cylinder Head

If you are in demand for superior quality and affordable OEM Toyota RAV4 Cylinder Head, then shop with us! We own a wide range of the reduced-priced genuine Toyota RAV4 Cylinder Head. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota RAV4 Cylinder Head Parts Questions & Experts Answers

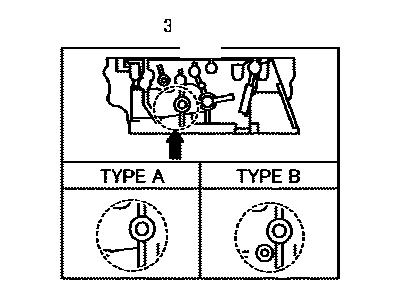

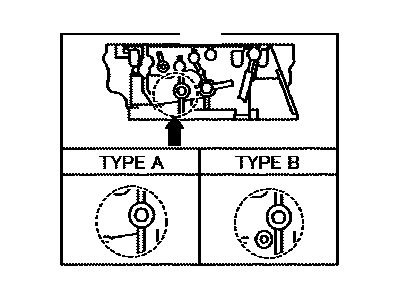

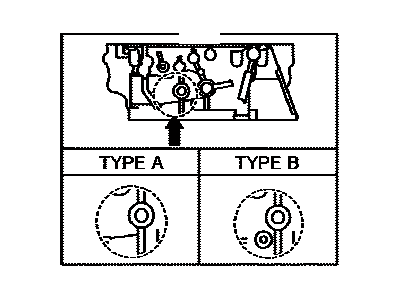

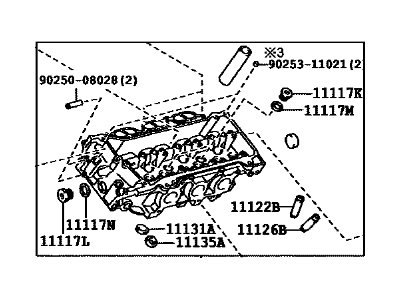

- Q: How to remove and install Cylinder Head on Toyota Rav4?A:Before removing the engine, set the fuel pump pressure to zero then disconnect the terminal on the battery's negative side. Dispose of the coolant, and unbolt the engine to take it out of the car. Next, one removes the drivebelt and alternator, then the valve cover as well out of the car. The final steps involve the removal of throttle body, fuel injectors and fuel rail, furthermore, the intake and Exhaust Manifolds should be disconnected. Continue with the dismantle of the Timing Chain and the camshaft sprockets and then the camshafts, the lifters and a camshaft housing. Remove the coolant hoses and electrical connections from the cylinder head and label for identification. A 10 mm hex-head socket bit with a breaker bar is needed to loosen it in an anti-clockwise way in a turn by turn procedure which should be simple to remove by hand, however, it is required to remove it in a reverse of the tightening sequence given so it is not warped or cracked. Raise the cylinder head off the engine block using a giddier, if necessary, and take out any further exterior fixtures for deep washing as well as checking. When installing the mating surfaces of the cylinder head and block have to be free of any carbon or any remains of the previous gasket and for that gasket scraper and brake system cleaner have to be used. The cylinders have to be plugged with clean shop rags to ensure that no foreign material gets inside the cylinders, in case of accumulation of material in the cylinders it can be vacuum cleaned. The mating surfaces of the block and cylinder head should be inspected, and this can be done, and corrected with a file if they are slightly raised, or brought to a machinist for further work if severely raised. Tap a thread of the correct size in the cylinder head bolt holes and using the compressed air, clean the holes with appropriate protection of the eye. Put back the components taken from the cylinder head, align the new gasket with the dowel pin hole in the block and spread the RTV sealant to the ends of the cylinder head gasket. Place the cylinder head back on the block without shifting the gasket as you tighten the head bolts in a star pattern until they are tightened hand-tight with clean engine oil put on the threads of the bolts and under the bolt heads new cylinder head . Perform the subsequent steps in the given order to apply the force and tighten the bolts to the prescribed torque. The rest of the installation process is the exact opposite of the removal process. This should be followed by at least one day before oil and coolant replenishment and starter motoring as well as looking for leaks and, finally, changing the engine oil and filter, refilling the cooling system, running the engine, and checking for leaks.

Related Toyota RAV4 Parts

Browse by Year

2024 Cylinder Head 2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head