My Garage

My Account

Cart

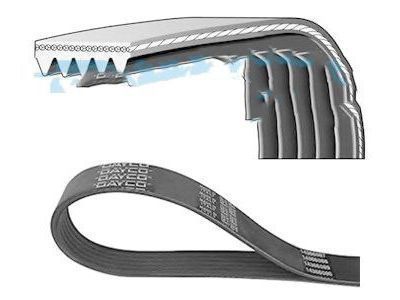

Genuine Toyota RAV4 Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Drive Belts found

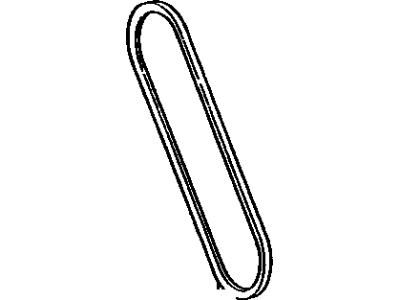

Toyota RAV4 V-Ribbed Belt

Part Number: 90916-A2021$25.45 MSRP: $35.58You Save: $10.13 (29%)Ships in 1-3 Business DaysToyota RAV4 V-Ribbed Belt

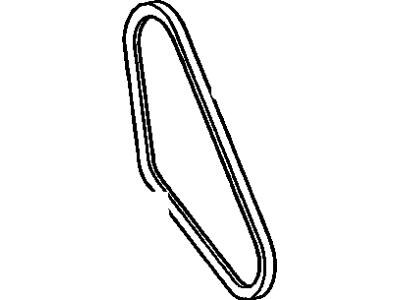

Part Number: 90916-A2027$28.07 MSRP: $39.24You Save: $11.17 (29%)Ships in 1 Business DayToyota RAV4 V Belt

Part Number: 99367-C1550$43.54 MSRP: $60.87You Save: $17.33 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90916-02652$39.73 MSRP: $55.53You Save: $15.80 (29%)Ships in 1-3 Business DaysToyota RAV4 V-Ribbed Belt

Part Number: 90916-02667$25.45 MSRP: $35.58You Save: $10.13 (29%)Ships in 1-3 Business DaysToyota RAV4 V-Ribbed Belt

Part Number: 90916-02668$33.55 MSRP: $46.89You Save: $13.34 (29%)Ships in 1-3 Business DaysToyota RAV4 V-Ribbed Belt

Part Number: 90916-02778$29.38 MSRP: $41.07You Save: $11.69 (29%)Ships in 1-2 Business DaysToyota RAV4 V Belt

Part Number: 90916-02503$66.78 MSRP: $94.13You Save: $27.35 (30%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90916-02599$37.24 MSRP: $52.04You Save: $14.80 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90916-02355$17.12 MSRP: $23.93You Save: $6.81 (29%)Ships in 1-3 Business DaysToyota RAV4 V-Ribbed Belt

Part Number: 90916-02721$7.84 MSRP: $10.96You Save: $3.12 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90916-02597$43.54 MSRP: $60.87You Save: $17.33 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 99363-30760$8.44 MSRP: $11.79You Save: $3.35 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90916-02502$51.52 MSRP: $72.01You Save: $20.49 (29%)Ships in 1-2 Business DaysToyota RAV4 V Belt

Part Number: 99363-80760$8.44 MSRP: $11.79You Save: $3.35 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90916-02598$51.52 MSRP: $72.01You Save: $20.49 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 99365-31090$21.10 MSRP: $29.50You Save: $8.40 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90080-91099$17.60 MSRP: $24.60You Save: $7.00 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 90916-02596$48.42 MSRP: $67.69You Save: $19.27 (29%)Ships in 1-3 Business DaysToyota RAV4 V Belt

Part Number: 99365-91090$23.19 MSRP: $32.42You Save: $9.23 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 25 Results

Toyota RAV4 Drive Belt

The Drive Belt in Toyota RAV4 is indispensable for the ability of the engine to charge such parts as the alternator, and drive the A/C compressor. This belt usually over these parts and engages the crankshaft and the serpentine belt ensures transfer of power from the crankshaft to the parts. The longevity of the Drive Belt in RAV4 vehicles ranges between 100,000 miles before getting a replacement; however, any signs of tearing or dent on the belt should be replaced immediately to avoid straining other features and the engine. Some of the Drive Belt variants used in RAV4 models of the past years include those that can suit the particular transmissions of the vehicle. Starting from the simple flat belts that are commonly used to the modern timing Belt with teeth suitable for accurate movement the type proves to offer several benefits when it comes to its use, tractions and durability. As technologies for belts improved, Drive Belts are considered vital driving components in the mechanical tracts of Toyota RAV4 automobiles to manage power transmission.

If you are in demand for superior quality and affordable OEM Toyota RAV4 Drive Belt, then shop with us! We own a wide range of the reduced-priced genuine Toyota RAV4 Drive Belt. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

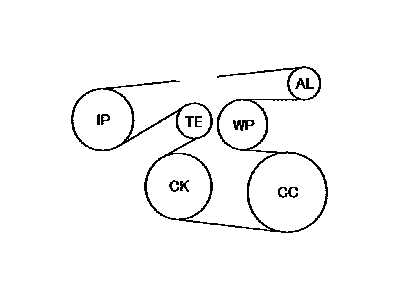

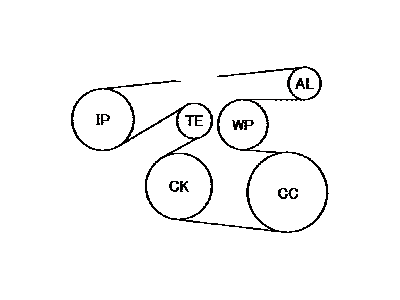

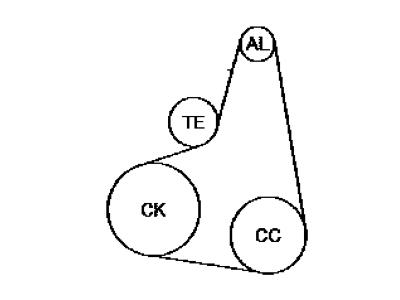

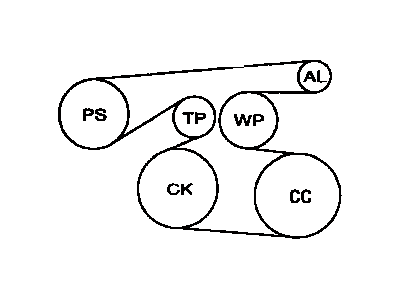

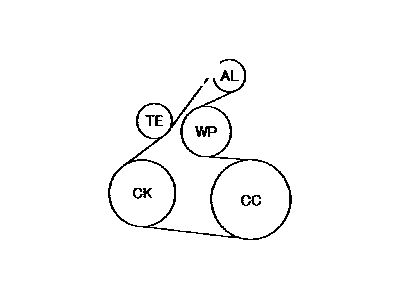

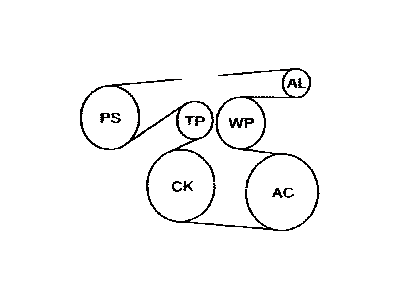

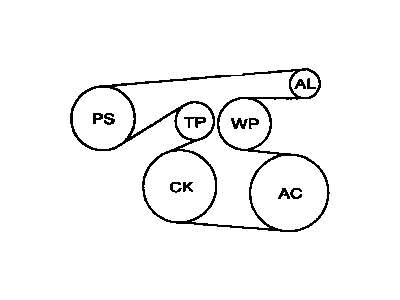

Toyota RAV4 Drive Belt Parts Questions & Experts Answers

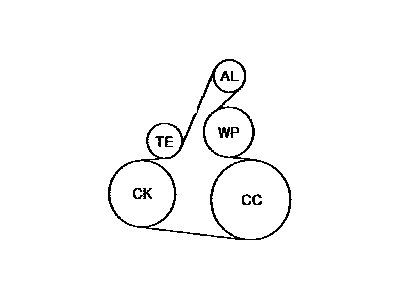

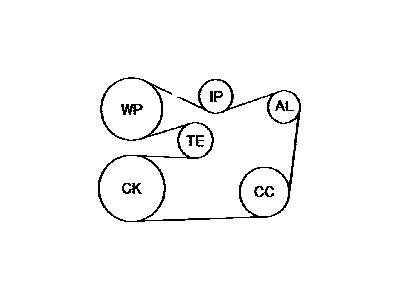

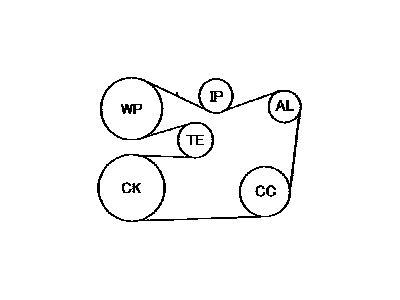

- Q: How to Inspect and Replace the Drive Belt on a Toyota RAV4?A:The drivebelt is located at the right end of the engine and its good condition is critical to the engine's operation. Over time, due to its composition and high stress, the drivebelt stretches and deteriorates, necessitating periodic inspections. A single serpentine drivebelt transmits power from the crankshaft to the alternator, water pump, and air conditioning compressor. With the engine stopped, inspect the full length of the drivebelt(s) for cracks and separation of the belt plies. It may be necessary to turn the engine clockwise using a wrench or socket and breaker bar on the crankshaft pulley bolt to thoroughly inspect the belt. Check for fraying, glazing, and any nicks, cracks, distortion, and corrosion on the pulleys. Small cracks in the edges of the belt ribs are not unusual and unless extensive or very deep, belt replacement is not essential. The drivebelt tension is adjusted automatically by a spring-loaded tensioner. To replace the belt, loosen the lug nuts of the right front wheel, raise the vehicle, support it securely on jackstands, and remove the right front wheel. Open the hood, remove the coolant expansion tank mounting bolts and set the tank aside. Remove the inner fender splash shield for access to the tensioner. Place a wrench on the hexagon portion of the tensioner and rotate it clockwise to release the tension. Slip the belt off the pulleys and slowly release the tensioner. Route the new belt over the pulleys, rotating the tensioner to allow the belt to be installed, then release the bell tensioner. Ensure the bell is properly centered in the pulleys. To replace a faulty tensioner, remove the drive-belt, then unscrew the mounting bolt. On 2017 and later models, the tensioner bolt is covered by a dust cap; use a screwdriver to remove the cap and access the mounting bolt. Installation is the reverse of the removal procedure. Finally, install the drivebelt.

Related Toyota RAV4 Parts

Browse by Year

2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt