My Garage

My Account

Cart

Genuine Toyota Sienna Wheel Cylinder

Brake Wheel Cylinder- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Wheel Cylinders found

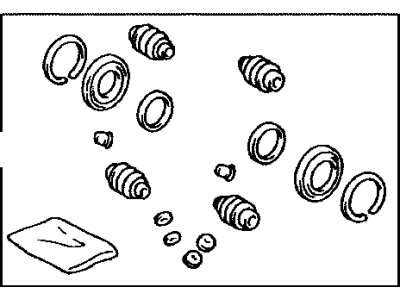

Toyota Sienna Cylinder Kit, Front Dis

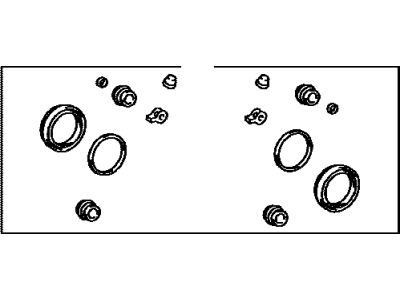

Part Number: 04478-0E030$51.75 MSRP: $72.34You Save: $20.59 (29%)Ships in 1-2 Business DaysToyota Sienna Rear Wheel Brake Cylinder Assembly

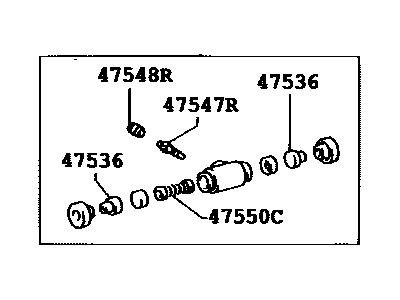

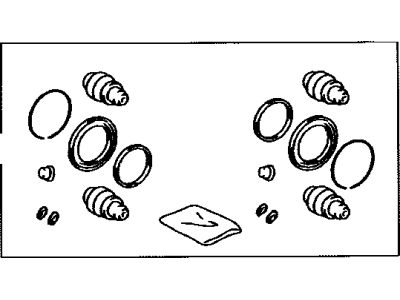

Part Number: 47550-08030$58.54 MSRP: $81.82You Save: $23.28 (29%)Ships in 1-2 Business DaysToyota Sienna Cylinder Kit, Front Dis

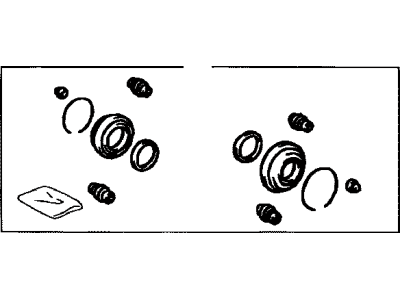

Part Number: 04478-0E050$37.59 MSRP: $52.54You Save: $14.95 (29%)Ships in 1-2 Business DaysToyota Sienna Rear Disc Brake Cylinder Kit

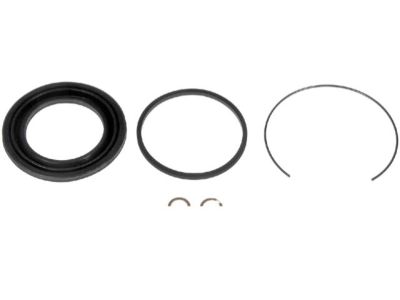

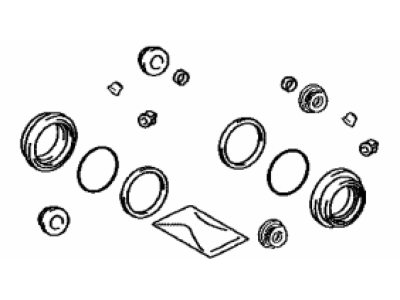

Part Number: 04479-0E060$36.88 MSRP: $51.54You Save: $14.66 (29%)Ships in 1-2 Business DaysToyota Sienna Rear Wheel Brake Cylinder Assembly

Part Number: 47550-08010$58.54 MSRP: $81.82You Save: $23.28 (29%)Ships in 1-3 Business DaysToyota Sienna Cylinder Kit, Rear Dis

Part Number: 04479-0E020$60.88 MSRP: $85.82You Save: $24.94 (30%)Ships in 1-3 Business DaysToyota Sienna Rear Disc Brake cylinder Kit

Part Number: 04479-28170$34.02 MSRP: $47.56You Save: $13.54 (29%)Ships in 1-3 Business DaysToyota Sienna Front Disc Brake Cylinder Kit

Part Number: 04479-08010$56.39 MSRP: $78.83You Save: $22.44 (29%)Ships in 1-3 Business DaysToyota Sienna Rear Disc Brake cylinder Kit

Part Number: 04479-28120$34.02 MSRP: $47.56You Save: $13.54 (29%)Ships in 1-3 Business DaysToyota Sienna Front Disc Brake Cylinder Kit

Part Number: 04478-08100$75.15 MSRP: $105.94You Save: $30.79 (30%)Ships in 1-3 Business DaysToyota Sienna Cylinder Kit, Rear Dis

Part Number: 04479-0E080$136.05 MSRP: $193.42You Save: $57.37 (30%)Ships in 1-3 Business DaysToyota Sienna Rear Disc Brake Cylinder Kit

Part Number: 04479-02470$37.59 MSRP: $52.54You Save: $14.95 (29%)Ships in 1-3 Business DaysToyota Sienna Front Disc Brake Cylinder Kit

Part Number: 04479-06060$62.65 MSRP: $88.31You Save: $25.66 (30%)Ships in 1-3 Business DaysToyota Sienna Front Disc Brake Cylinder Kit

Part Number: 04479-08020$62.65 MSRP: $88.31You Save: $25.66 (30%)Ships in 1-3 Business DaysToyota Sienna Front Disc Brake Cylinder Kit

Part Number: 04478-08081$62.65 MSRP: $88.31You Save: $25.66 (30%)

Toyota Sienna Wheel Cylinder

If you are in demand for superior quality and affordable OEM Toyota Sienna Wheel Cylinder, then shop with us! We own a wide range of the reduced-priced genuine Toyota Sienna Wheel Cylinder. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Sienna Wheel Cylinder Parts Questions & Experts Answers

- Q: How to remove and install a wheel cylinder on Toyota Sienna?A:If an overhaul is indicated, usually due to fluid leakage or sticking brakes, explore all options before beginning the job. New wheel cylinders are available, making this task quite easy, and if the vehicle has high mileage, new wheel cylinders (not rebuilt) are highly recommended. Always replace both wheel cylinders at the same time rather than just one. To begin, raise the rear of the vehicle and support it securely on jackstands, blocking the front wheels to prevent rolling. Remove the brake shoe assembly and clean all dirt and foreign material from around the wheel cylinder. Disconnect the Brake Line using a flare-nut wrench if available, then unscrew the hydraulic line-to-wheel cylinder threaded fitting and remove the mounting bolts without pulling the brake line away from the wheel cylinder. Next, remove the wheel cylinder mounting bolts, detach the wheel cylinder from the brake backing plate, and place it on a clean workbench, immediately plugging the brake line to prevent fluid loss and contamination. For installation, position the new wheel cylinder and install the bolts finger tight, then connect the brake line to the cylinder, ensuring not to cross thread the fitting, and tighten the wheel cylinder bolts to the specified torque. Tighten the brake line fitting and reinstall the brake shoes and drum. Bleed the brakes, install the wheel and lug nuts, lower the vehicle to the ground, and tighten the lug nuts to the specified torque. Finally, check the operation of the brakes carefully before driving the vehicle.

Related Toyota Sienna Parts

Browse by Year

2023 Wheel Cylinder 2022 Wheel Cylinder 2021 Wheel Cylinder 2020 Wheel Cylinder 2019 Wheel Cylinder 2018 Wheel Cylinder 2017 Wheel Cylinder 2016 Wheel Cylinder 2015 Wheel Cylinder 2014 Wheel Cylinder 2013 Wheel Cylinder 2012 Wheel Cylinder 2011 Wheel Cylinder 2010 Wheel Cylinder 2009 Wheel Cylinder 2008 Wheel Cylinder 2007 Wheel Cylinder 2006 Wheel Cylinder 2005 Wheel Cylinder 2004 Wheel Cylinder 2003 Wheel Cylinder 2002 Wheel Cylinder 2001 Wheel Cylinder 2000 Wheel Cylinder 1999 Wheel Cylinder 1998 Wheel Cylinder