My Garage

My Account

Cart

Genuine Toyota Solara Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Ball Joints found

Toyota Solara Front Upper Left Suspension Ball Joint Assembly

Part Number: 43340-09010$65.24 MSRP: $91.97You Save: $26.73 (30%)Ships in 1-3 Business DaysToyota Solara Lower Ball Joint Assembly Front Right

Part Number: 43330-09560$70.79 MSRP: $99.79You Save: $29.00 (30%)Ships in 1-3 Business DaysToyota Solara Front Left Lower Suspension Ball Joint Assembly

Part Number: 43330-09051$69.84 MSRP: $98.45You Save: $28.61 (30%)Ships in 1-3 Business DaysToyota Solara Lower Ball Joint Assembly Front Right

Part Number: 43330-09160$70.79 MSRP: $99.79You Save: $29.00 (30%)Ships in 1-2 Business DaysToyota Solara Front Right Lower Suspension Ball Joint Assembly

Part Number: 43330-09050$70.67 MSRP: $99.62You Save: $28.95 (30%)Ships in 1-3 Business Days

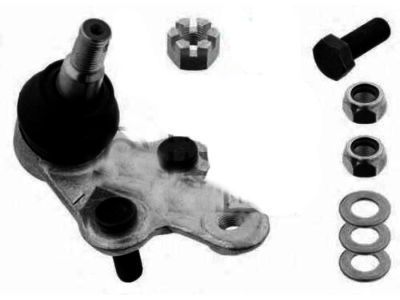

Toyota Solara Ball Joint

If you are in demand for superior quality and affordable OEM Toyota Solara Ball Joint, then shop with us! We own a wide range of the reduced-priced genuine Toyota Solara Ball Joint. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Solara Ball Joint Parts Questions & Experts Answers

- Q: How to Detach and Install a Ball Joint Using the Picklefork and Puller Methods on a 2002-2008 Toyota Solara?A:Open the hub cap and then unbolt half of the wheel lug nuts, lift the vehicle up using a jack and put it on jack stands, after that finally you can remove the wheel. If intending to use a puller for the balljoint, the driveaxle/hub nut should be loosened before lifting the car. Loosen the nut and counter nut without the removal of the cotter pin from the ball joint stud located on the new shackle. Access the balljoint and using a pickle fork-type separator push the balljoint off the Steering Knuckle ensuring that the rubber boot has been greased to avoid it getting damaged, then remove the balljoint stud nut. Subsequently, first, take out the bolt and nuts holding the balljoint to the Control Arm in order to disengage the balljoint from the control arm with the help of a prybar. To install the balljoint on the steering knuckle and it is recommended to install the nut into place but do not over tighten the nut. After that, connect the balljoint to the control arm, screw in the bolt and nuts, and thread it to the suitable torque. Turn head Allen to the specified torque and install a new cotter pin, if it does not coincide with the slots of the nut, turn the nut further without its undoing. Then hang the wheel and the lug nuts, lower the car and again, tighten the lug nuts to the recommended torque. For the puller method, disconnect the control arm from the ball joint, remove the outer end of the drive axle from the steering knuckle with the help of the tool, and holding it with wire. Take out the cotter pin from the balljoint stud and then slacken the nut, although it may not be removed off completely. Insert a small puller to free the stud from the steering knuckle by pulling it out, then you unscrew the nut and the balljoint. Place the new balljoint into the steering knuckle and tighten the nut with requested torque in the instruction specifications, put a new cotter pin in alignment. Place the outer end of the driveaxle through the steering knuckle and screw on the nut and tighten it to some extent but do not over- tighten it. Fix the balljoint to the lower arm and tighten the fasteners to the next mentioned torque. Lastly, the wheel and lugs nuts are fitted and the vehicle raised then the lug nuts are tightened to the appropriate torque setting then the driveaxle/hub is tightened to the appropriate torque and a lock washer/cotter pin is fitted.