My Garage

My Account

Cart

Genuine Toyota Tacoma Air Injection Pump

SAI Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Air Injection Pumps found

Toyota Tacoma Air Pump Assembly

Part Number: 17610-0W020$527.61 MSRP: $787.09You Save: $259.48 (33%)Ships in 1-2 Business DaysToyota Tacoma Pump Assy, Air

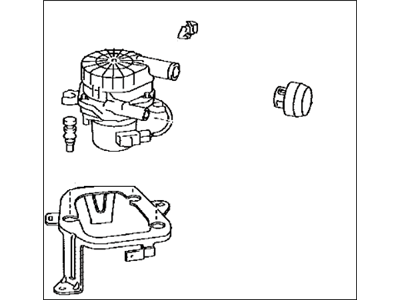

Part Number: 17600-0C020$555.99 MSRP: $830.16You Save: $274.17 (34%)Ships in 1-3 Business DaysToyota Tacoma Pump Assembly, Air W/BRA

Part Number: 17600-0C040$588.96 MSRP: $879.40You Save: $290.44 (34%)Ships in 1-3 Business DaysToyota Tacoma Pump Assembly, Air W/BRA

Part Number: 17600-0P040$642.77 MSRP: $959.74You Save: $316.97 (34%)Ships in 1-3 Business DaysToyota Tacoma Air Pump Assembly

Part Number: 17610-0C050$508.87 MSRP: $759.14You Save: $250.27 (33%)Ships in 1-3 Business Days

Toyota Tacoma Air Injection Pump

If you are in demand for superior quality and affordable OEM Toyota Tacoma Air Injection Pump, then shop with us! We own a wide range of the reduced-priced genuine Toyota Tacoma Air Injection Pump. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Tacoma Air Injection Pump Parts Questions & Experts Answers

- Q: What Is the Purpose of the Air Injection System and Air Injection Pump and How Do You Replace on Toyota Tacoma?A:An air injection system is applied to some four-cylinder engines to help catalytic converters warm up and reach their optimal working temperature during the warm-up modes. PCM, electric air pump, air injection control valve, air pressure sensor, air injection control driver make up this system. The PCM draws information from the CKP sensor, ECT sensor, and MAF/IAT sensor to know the temperature of the engine. If the engine is cold the PCM is determining the amount of air that is needed to warm up the catalysts, the air injection system is activated for a maximum at 80 seconds. The air injection control driver involved turns on the electric air pump and control valve which injects air into the exhaust ports, helping in burning the unburned fuel fumes commonly experienced during warm-ups. It also increases the rate at which exhaust gases and the earlier located catalysts in the pipe are heated. However, most of the components of the air injection system are very reliable; nonetheless, the air pressure sensor, electric air switching valve, the air pump can be replaced if they fail-which in certain situations may necessitate removal of Intake manifold. Air pump assembly is mounted in the right-front corner of the engine compartment while the air switching valve assembly is mounted at the top of the exhaust manifold. It is situated on the back part of intake air connector as the air pressure sensor. These components include electrical connectors and hoses, together with the mounting bolts used in their removal and installation processes, where the sequence is to disconnect and later reconnect but ensure that when connecting, new gasket is used where required.

Related Toyota Tacoma Parts

Browse by Year

2023 Air Injection Pump 2022 Air Injection Pump 2021 Air Injection Pump 2020 Air Injection Pump 2019 Air Injection Pump 2018 Air Injection Pump 2017 Air Injection Pump 2016 Air Injection Pump 2015 Air Injection Pump 2014 Air Injection Pump 2013 Air Injection Pump 2012 Air Injection Pump 2011 Air Injection Pump 2010 Air Injection Pump 2009 Air Injection Pump 2008 Air Injection Pump 2007 Air Injection Pump 2006 Air Injection Pump 2005 Air Injection Pump