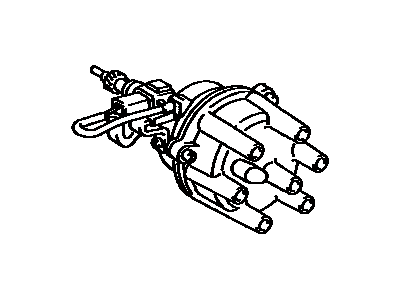

When working with models ranging from 1979 through 1982, one has to start by disconnecting the distributor together with the O-ring from the main body outer flange of the gear. To reach the pick-up coil assembly, the cover has to be unbolted, and the pick-up coil assembly has to be slid out; the clamp, which belongs to this mechanism, has to be pulled out using the corresponding screws. Then, unbolt the vacuum advance unit from the main body, use the DC probe to check the break points and then unscrew the breaker plate to eliminate it. Slide out the grease stopper in the top of the signal rotor, unscrew the top of the shaft and then disengage its rotor assembly and springs from the shaft noting that springs should be placed with their corresponding pegs. Take off the shaft advance weights by unlodging the E-clips from the pivot shafts, and by broaching the opposite end of the pin and knocking the pin out of the gear; to dismantle the rotor shaft from the distributor body is gently eased out. Remove any dirt in the metal parts by using solvent, and dry the metal parts and check the cap for crack, the burnt or corroded terminals of the rotor, the rotation of the breaker plate, the gear, shaft bearing, housing for wear check the signal rotor for the smooth movement on the shaft with little side play check the centrifugal advance springs for crack and for sagging while checking the centrifugal weights the pick-up coil measurement by ohmm In the corresponding steps, replace any worn, damaged, or defective components before reassembling the item in the reverse manner and lubricate the shaft and bearing part with some oil before the others. Most the locating mark and stopper, then mount the signal rotor in the shaft and toggle the centrifugal advance by rotating the rotor to the right and letting is go only for it to turn immediately back into position. Modify the separation distance of the signal rotor with the signal generator; subsequently, fasten the signal generator mounting screws. In case of the distributing assembly, models made from and after 1983 cannot be overhauled, whereas for the 1983 through 1988 non-turbo models and all turbo models of the car, only the distributor driven gear can be replaced, but for 1989 and later non-turbo units, machining is out of the question. If a new distributor or cam position sensor driven gear is required then first, take out the distributor or cam position sensor, then to fix the driven gear on the housing of the vise you need to drill a mark on the driven gear to match the groove on the housing of the vise. In the distributor shaft place a matchmark on the circumference against the groove in the housing. They grind off of the gear and the pin with a grinding wheel. Use hammer and punch to knock out the pin, now take out the old drive gear, this one we can throw away. Next, ensure that the matchmark on the shaft tallies with the mark made when drilling the new gear into the housing; you can then hammer in a new pin with the help of punch to restring the distributor or cam position sensor back into place.

Posted by ToyotaPartsDeal Specialist