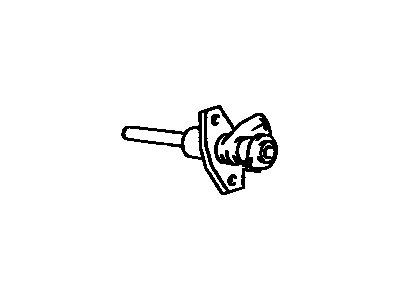

To check for malfunctioning injectors, start the engine and listen to each injector using a stethoscope or screwdriver, ensuring a steady clicking sound that corresponds to engine speed; if no sound or an unusual sound is heard, inspect the wiring connections. If a stethoscope is unavailable, feel for rhythmic clicking with your finger on each injector. To measure injector resistance, unplug the electrical connector and use an ohmmeter, comparing the readings to the specified resistance values; replace any injector that falls outside the acceptable range. For removal, relieve the system fuel pressure, then on specific models, remove the air intake chamber or throttle body as needed, and disconnect the electrical connectors from the injectors. Detach the fuel injector wiring harness and, for certain models, disconnect the cold start injector tube. Remove the pulsation damper or banjo bolt as applicable, ensuring to discard old sealing washers. Catch any spilled fuel by placing a rag or container under the pressure regulator before detaching the fuel return hose. If replacing the fuel pressure regulator, do so before unbolting the fuel rail, then remove the retaining bolts and extract the fuel rail and injectors as a single assembly, discarding the old insulators. Pull the injectors from the fuel rail, removing the O-rings while keeping the cover on the injector tips intact. For installation, replace the grommet and O-ring on each injector, coating them with fuel before assembly, and ensure proper alignment. Insert new insulators into the intake manifold, install the injectors and delivery pipe, and check for smooth rotation; if not, replace the O-rings. Tighten the retaining bolts to the specified torque, and verify there are no fuel leaks by bridging the terminals in the fuel pump check connector and turning the ignition switch to On, repairing any leaks immediately before replacing the connector plug.

Posted by ToyotaPartsDeal Specialist