My Garage

My Account

Cart

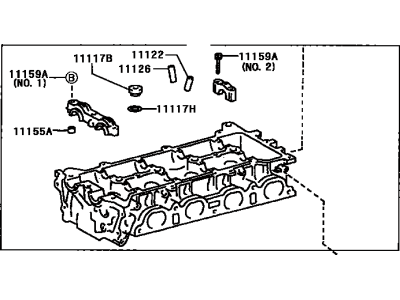

Genuine 1990 Toyota Celica Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Cylinder Heads found

1990 Toyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-19265$814.82 MSRP: $1034.70You Save: $219.88 (22%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Sub-Assy, Cylinder; Cylinder Head

- Part Name Code: 11101

- Item Weight: 26.30 Pounds

- Item Dimensions: 22.3 x 12.2 x 10.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-19265

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

1990 Toyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-74110$940.85 MSRP: $1194.73You Save: $253.88 (22%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Sub-Assy, Cylinder

- Replaced by: 11101-74901

- Part Name Code: 11101

- Item Weight: 26.30 Pounds

- Item Dimensions: 21.7 x 12.2 x 10.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-74110

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Head Sub-Assy, Cylinder

- Part Name Code: 11101

- Item Weight: 26.30 Pounds

- Item Dimensions: 22.3 x 12.7 x 10.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-88384

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

1990 Toyota Celica Cylinder Head

With ToyotaPartsDeal.com, you have access to an extensive inventory of genuine 1990 Toyota Celica Cylinder Head, all priced competitively. Feel secure in your purchase, as all our OEM 1990 Toyota Celica Cylinder Head are covered by the manufacturer's warranty. Plus, we offer a hassle-free return policy and speedy delivery service.

1990 Toyota Celica Cylinder Head Parts Questions & Experts Answers

- Q: What are the steps involved in the thorough cleaning and inspection of the cylinder head and valve train components during an engine overhaul for the 1990 Toyota Celica?A: Thorough cleaning of the cylinder head and related valve train components, followed by a detailed inspection, will enable you to decide how much valve service work must be done during the engine overhaul. Begin by scraping all traces of old gasket material and sealing compound off the head gasket, intake manifold, and exhaust manifold sealing surfaces, taking care not to gouge the cylinder head. Use special gasket removal solvents available at auto parts stores to ease this process. Remove built-up scale from the coolant passages and run a stiff wire brush through various holes to eliminate deposits. Use an appropriate size tap in each threaded hole to remove corrosion and thread sealant, clearing debris with compressed air while wearing eye protection. Clean the exhaust and intake manifold stud threads with a wire brush, then clean the cylinder head with solvent and dry it thoroughly, using compressed air to speed up the drying process. Decarbonizing chemicals may be useful but should be handled with caution. Clean the lifters and rocker arms with solvent, ensuring they are dried thoroughly without mixing them up, and clean all valve springs, spring seats, keepers, and retainers one at a time to avoid confusion. Scrape heavy deposits from the valves and use a motorized wire brush for the valve heads and stems, ensuring not to mix them up. Inspect the head for cracks, coolant leakage, and other damage, consulting an automotive machine shop if necessary. Check the head gasket mating surface for warpage using a straightedge and feeler gauge, and examine the valve seats for pitting, cracking, or burning, which may require professional service. Measure the valve guide inside diameter and valve stem diameter to determine stem-to-guide clearance, checking for excessive movement with a dial indicator. Inspect each valve face for wear, deformation, and cracks, and measure the margin width to ensure it meets specifications. Check valve springs for wear and free length, ensuring they are not shorter than specified, and assess their squareness on a flat surface. Inspect spring retainers and keepers for wear and cracks, replacing any questionable parts, and replace any damaged or excessively worn components. If the inspection indicates that the valve components are in poor condition, reassemble the valves in the cylinder head and follow valve servicing recommendations.