My Garage

My Account

Cart

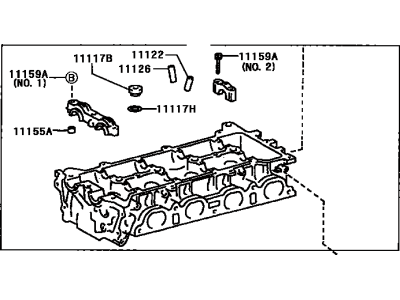

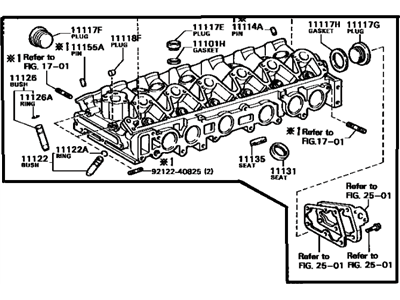

Genuine Toyota Celica Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Cylinder Heads found

Toyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-22052$899.83 MSRP: $1142.64You Save: $242.81 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-74160$614.98 MSRP: $780.93You Save: $165.95 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-19265$814.82 MSRP: $1034.70You Save: $219.88 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-79225$1005.85 MSRP: $1277.28You Save: $271.43 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-22051$899.83 MSRP: $1142.64You Save: $242.81 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-09040$1005.85 MSRP: $1277.28You Save: $271.43 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-49208$507.28 MSRP: $650.02You Save: $142.74 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-49255$615.81 MSRP: $781.97You Save: $166.16 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-29445$643.90 MSRP: $817.66You Save: $173.76 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-88386$734.13 MSRP: $941.54You Save: $207.41 (23%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-49296$844.68 MSRP: $1083.34You Save: $238.66 (23%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-74030$940.85 MSRP: $1194.73You Save: $253.88 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-74110$940.85 MSRP: $1194.73You Save: $253.88 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-29475$968.19 MSRP: $1229.45You Save: $261.26 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-29465$970.70 MSRP: $1232.63You Save: $261.93 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-49295$1443.14 MSRP: $1849.44You Save: $406.30 (22%)Ships in 1-3 Business DaysToyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-39196$191.04 MSRP: $235.11You Save: $44.07 (19%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 31 Results

Toyota Celica Cylinder Head

If you are in demand for superior quality and affordable OEM Toyota Celica Cylinder Head, then shop with us! We own a wide range of the reduced-priced genuine Toyota Celica Cylinder Head. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Celica Cylinder Head Parts Questions & Experts Answers

- Q: Is it more practical and economical for the home mechanic to purchase a replacement cylinder head rather than disassembling, inspecting, and reconditioning the original on Toyota Celica?A:While machined cylinder heads can be rebuilt by the home mechanic by the removal of old, worn or damaged parts, purchase of a new or a re-manufactured head is relatively easier and cheaper to acquisition especially due to shortage and unavailability of some cylinder head parts for one to work on the original cylinder head. Disassembly requires the intake and the exhaust valves and related parts to be also pulled off the engine block provided the lifters, rocker arms and camshaft have been pulled out. It is necessary to sort the valves and their components prior to disposal by marking them in a way that makes it possible to reinstall them in their corresponding valve guides. To dismantle the first valve, first, use the spring compressor to compact the springs and pull out their keepers and then, while slowly releasing the compressor, take off the retainer, spring soldier and, if any, the spring seat. One has to be very careful not to damage the lifter bores when compressing the valve springs, but this mainly applies to other engines apart from the 2S-E units. Once the valve has been pulled out, the guide oil seal should also be also removed out of the guide and in case the valve has a binding problem, it may also be necessary to deburr that area especially round the keeper groove. This process should be done for the other valves and all the parts of each valve should be labeled or packed together for ease of reassembly. After all the valves and other parts have been dismantled and arranged systematically, the head should be washed and inspected carefully; additionally, the engine should be dismantled if a thorough overhaul of the cylinder head is also planned before washing or cleaning and observing the condition of the head.

Related Toyota Celica Parts

Browse by Year

2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head 1986 Cylinder Head 1985 Cylinder Head 1984 Cylinder Head 1983 Cylinder Head 1982 Cylinder Head 1981 Cylinder Head 1980 Cylinder Head 1979 Cylinder Head 1978 Cylinder Head