My Garage

My Account

Cart

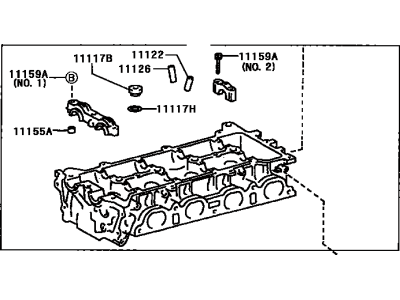

Genuine 1992 Toyota Celica Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Cylinder Heads found

1992 Toyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-74160$614.98 MSRP: $780.93You Save: $165.95 (22%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Sub-Assy, Cylinder

- Manufacturer Note: (J)

- Part Name Code: 11101

- Item Weight: 27.80 Pounds

- Item Dimensions: 21.9 x 12.1 x 10.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-74160

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

1992 Toyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-19265$814.82 MSRP: $1034.70You Save: $219.88 (22%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Sub-Assy, Cylinder; Cylinder Head

- Part Name Code: 11101

- Item Weight: 26.30 Pounds

- Item Dimensions: 22.3 x 12.2 x 10.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-19265

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

1992 Toyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-88386$734.13 MSRP: $941.54You Save: $207.41 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Sub-Assy, Cylinder

- Part Name Code: 11101

- Item Weight: 28.40 Pounds

- Item Dimensions: 21.5 x 12.3 x 10.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-88386

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

1992 Toyota Celica Cylinder Head Sub-Assembly

Part Number: 11101-74110$940.85 MSRP: $1194.73You Save: $253.88 (22%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Sub-Assy, Cylinder

- Replaced by: 11101-74901

- Part Name Code: 11101

- Item Weight: 26.30 Pounds

- Item Dimensions: 21.7 x 12.2 x 10.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-74110

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Head Sub-Assy, Cylinder

- Part Name Code: 11101

- Item Weight: 26.10 Pounds

- Item Dimensions: 21.9 x 12.2 x 10.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-88389

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Head Sub-Assy, Cylinder

- Part Name Code: 11101

- Item Weight: 26.30 Pounds

- Item Dimensions: 22.3 x 12.7 x 10.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-88384

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

- Product Specifications

- Other Name: Head Sub-Assy, Cylinder; Cylinder Head

- Part Name Code: 11101

- Item Weight: 26.10 Pounds

- Item Dimensions: 21.5 x 12.1 x 10.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-88391

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

1992 Toyota Celica Cylinder Head

With ToyotaPartsDeal.com, you have access to an extensive inventory of genuine 1992 Toyota Celica Cylinder Head, all priced competitively. Feel secure in your purchase, as all our OEM 1992 Toyota Celica Cylinder Head are covered by the manufacturer's warranty. Plus, we offer a hassle-free return policy and speedy delivery service.

1992 Toyota Celica Cylinder Head Parts Questions & Experts Answers

- Q: How to remove and install a cylinder head for the 1992 Toyota Celica?A: Before carrying out this process, the engine should preferably be cold, but in any case, it should be allowed to cool down fully. The preliminary steps to begin the process should include turning off the negative terminal cable from the battery, next, the coolant from the engine block and radiators should be drained, then after, the engine oil and the oil filter should be drained. Next, throttle body, injectors, and fuel rails should be unplugged, and then remove the intake manifold, exhaust manifold. Rmucket the timing belt as well as the upper idler pulley sprocket and additionally for the 2S-E engines, extract the camshaft as well as the camshaft housing; for all the other mentioned engines, it will be the camshafts and lifters while for 3S-FE, 5S-FE and 3S-GE engines, the rear timing belt cover should be pulled off. Remove the alternator and distributor bolts, and then remove the power steering pump bolt but do not detach the hoses. Ensure the cylinder head, remove any remaining labels or any items such as coolant fittings tubes cables wires or hoses that may be sticking out of the head. With a breaker bar and the correct Allen-head driver or socket, turn the cylinder head bolts 1/4 turn at a time and as far as the can be turned by hand without use of the breaker bar; since turning them in the right sequence help in avoid warping or cracking of the head. Raise the cylinder head off the engine block carefully if it is seized and stripped the head of all accessories for cleaning and examination of the head surface. The bores on both the cylinder head and block must be impeccably clean for copious seal when the head is fitted; you can employ a gasket scraper to take off any remaining carbon deposits as well as old gasket and clean the surface with lacquer thinner and acetone. Lightly scratch the meeting planes of the block and head and if there is need of a little sharpening you could do so by filing or through machining. Run the appropriate tap through the threads in the head bolt holes, and blow out the holes with compressed air. Mount each bolt in a vise and roll a die down the threads to clean them off and bring them back to the correct size. Reinstall the removed components into the head, fit the new gasket over the dowel pin on the block and before tightening the head bolts, carefully lowering the head onto the block and center the gasket. Ensure that before tightening, you use a small quantity of clean engine oil on the holes where the head bolts are to be tightened and when tightening the bolts ensure that you tighten them by hand. As described above, successively increase the torque of the bolts up to the required values. The remaining installation steps are the reverse of removal and for all but the 2S-E engines the usual checking and adjustment of the valves should be made. The procedures that can be done include: refilling the cooling system with water, replacing the oil filter, and putting some quantities of oil in the engine. Last, crank the vehicle, look for the leakage, adjust the ignition timing and test the vehicle on the road.