My Garage

My Account

Cart

Genuine Toyota 4Runner Air Injection Pump

SAI Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Air Injection Pumps found

Toyota 4Runner Pump Assy, Air

Part Number: 17600-0F010$468.40 MSRP: $698.76You Save: $230.36 (33%)Ships in 1-3 Business DaysToyota 4Runner Air Pump Assembly

Part Number: 17610-0C010$419.79 MSRP: $626.23You Save: $206.44 (33%)Ships in 1-3 Business DaysToyota 4Runner Air Pump Assembly

Part Number: 17610-0C030$505.31 MSRP: $753.82You Save: $248.51 (33%)Ships in 1-3 Business DaysToyota 4Runner Air Pump Assembly

Part Number: 17610-0C040$456.58 MSRP: $681.13You Save: $224.55 (33%)Ships in 1-3 Business Days

Toyota 4Runner Air Injection Pump

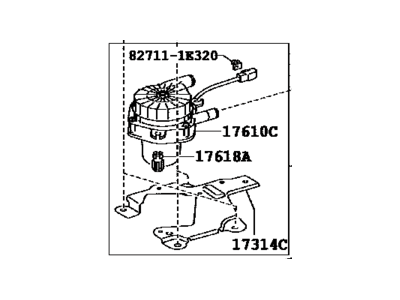

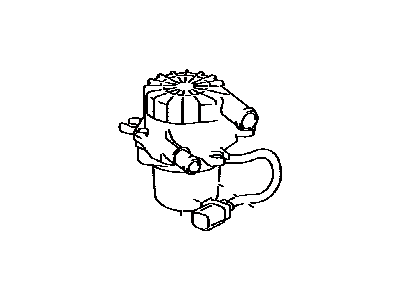

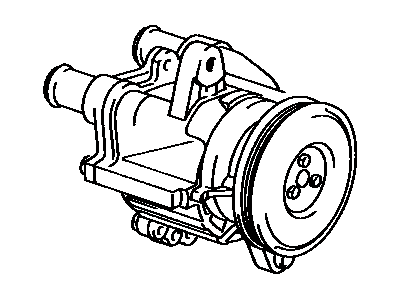

The Toyota Air Injection Pump, which exists in Toyota 4Runner models, forms a part of the secondary Air Injection Pump system to introduce fresh air into the exhaust system. The oxidation of remaining fuel increases through this procedure, which results in lowered hydrocarbons (HC) and carbon monoxide (CO) emissions. During operations, the Toyota system uses either electric or belt-driven 4Runner Air Injection Pump to create pressurized air that directs toward exhaust ports and the catalytic converter at different points according to engine temperature conditions. When the engine needs warming up, the air control valve sends air to the manifold to reduce emissions resulting from a fuel-rich mixture. The engine will transition to use air delivery to the catalytic converter when it achieves its normal operating temperature. The Toyota system safeguards itself with a diverter valve that stops backfires during slowing down, besides using one-way check valves to shield the 4Runner Air Injection Pump from hot exhaust gases. Homes and check valves require regular inspections for sustaining Toyota system performance and integrity.

If you are in demand for superior quality and affordable OEM Toyota 4Runner Air Injection Pump, then shop with us! We own a wide range of the reduced-priced genuine Toyota 4Runner Air Injection Pump. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota 4Runner Air Injection Pump Parts Questions & Experts Answers

- Q: What is the function of the air injection system and how to replace Air Injection Pump on Toyota 4Runner?A:For best efficiency the upstream catalytic converters first have to reach an effective operating temperature during warm up and for this reason an air injection system is installed in the 2005 and later models of V8 cars. The components include the PCM, the CIAICD, the electric air pump, the air pressure sensor, the EASV, two VSVs and two worth of vacuum type air switching valves and corresponding plumbing and wiring harnesses. The PCM employing the information from the ECT and IAT sensors to determine the engine temperature and estimating the right amount of air needed to warm up the catalysts in case the engine is cold. When triggered, the PCM makes the VSVs turn on, AI control driver, the air pump and electric air switching valve and lets air into the exhaust manifolds which assists in burning the unburned fuel vapor residues and at the same time the heating of the exhaust gases and upstream catalysts. The air injection system is considered reasonably robust and few failures occur, however where a failure has occurred then component replacement/renovation could be required, and some of these component may require intake manifold removal to access. Air injection control driver is to the left of the engine compartment sill while the VSVs are on the right side of intake manifold. As it can be observed, the vacuum-type air switching valves are found at the back of the engine and they are attached to the rear coolant bypass housing. Concerning the air pressure sensor, electric air switching valve, the air pump the intake manifold must to be unplugged. Each of them can be disconnected and separated; installation means the reverse of removal; if some gaskets were replaced, it is necessary to use new ones. If replacing the air pump, the air pressure sensor and the air switching valve can be incorporated in a single module that can be easily serviced.

Related Toyota 4Runner Parts

Browse by Year

2024 Air Injection Pump 2023 Air Injection Pump 2022 Air Injection Pump 2021 Air Injection Pump 2020 Air Injection Pump 2019 Air Injection Pump 2018 Air Injection Pump 2017 Air Injection Pump 2016 Air Injection Pump 2015 Air Injection Pump 2014 Air Injection Pump 2013 Air Injection Pump 2012 Air Injection Pump 2011 Air Injection Pump 2010 Air Injection Pump 2009 Air Injection Pump 2008 Air Injection Pump 2007 Air Injection Pump 2006 Air Injection Pump 2005 Air Injection Pump 2004 Air Injection Pump 1991 Air Injection Pump 1990 Air Injection Pump 1989 Air Injection Pump 1988 Air Injection Pump 1987 Air Injection Pump 1985 Air Injection Pump 1984 Air Injection Pump