My Garage

My Account

Cart

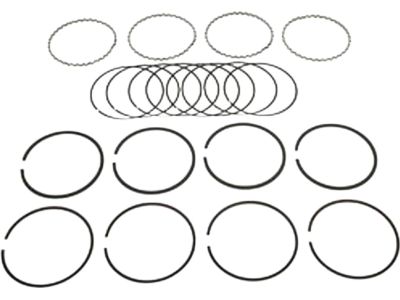

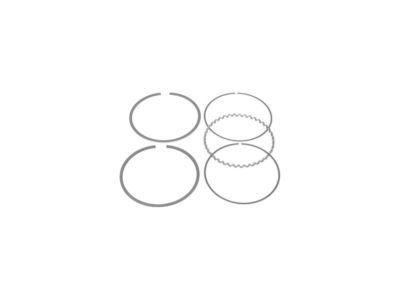

Genuine Toyota 4Runner Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

45 Piston Ring Sets found

Toyota 4Runner Piston Ring Set

Part Number: 13011-31100$301.70 MSRP: $432.62You Save: $130.92 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-75110$178.40 MSRP: $255.81You Save: $77.41 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-31210$243.94 MSRP: $349.78You Save: $105.84 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-35052$202.29 MSRP: $290.07You Save: $87.78 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-75041$323.28 MSRP: $463.56You Save: $140.28 (31%)Ships in 1 Business DayToyota 4Runner Piston Ring Set

Part Number: 13013-62100$401.28 MSRP: $598.62You Save: $197.34 (33%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-65021$257.90 MSRP: $369.82You Save: $111.92 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-62060$257.90 MSRP: $369.82You Save: $111.92 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-50160$422.02 MSRP: $629.56You Save: $207.54 (33%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13013-75110$213.08 MSRP: $305.54You Save: $92.46 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13013-50140$524.63 MSRP: $782.64You Save: $258.01 (33%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-62100$342.07 MSRP: $490.51You Save: $148.44 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13013-75041$364.93 MSRP: $544.40You Save: $179.47 (33%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13013-65021$318.69 MSRP: $456.98You Save: $138.29 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13013-62110$401.28 MSRP: $598.62You Save: $197.34 (33%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13013-50160$467.14 MSRP: $696.88You Save: $229.74 (33%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13015-35041$213.36 MSRP: $305.93You Save: $92.57 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-62110$342.07 MSRP: $490.51You Save: $148.44 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-35050$202.29 MSRP: $290.07You Save: $87.78 (31%)Ships in 1-3 Business DaysToyota 4Runner Piston Ring Set

Part Number: 13011-50161$422.02 MSRP: $629.56You Save: $207.54 (33%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 45 Results

Toyota 4Runner Piston Ring Set

If you are in demand for superior quality and affordable OEM Toyota 4Runner Piston Ring Set, then shop with us! We own a wide range of the reduced-priced genuine Toyota 4Runner Piston Ring Set. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota 4Runner Piston Ring Set Parts Questions & Experts Answers

- Q: How Should Piston Ring Set End Gaps Be Checked and Corrected Before Installation on Toyota 4Runner?A:Before fitting the new piston rings, measure the ring ends and fine the right size for piston ring groove clearance. LIST: Piston/connecting rod assemblies, new ring sets, piston, and cylinder must be laid down so that the corresponding piston and cylinder can be compared during end gap measurement and subsequent assembly of the engine. Place the first ring with the land of the ring touching the cylinder's side wall, and insert it into cylinder, using the top of the piston, which should be near the bottom of the cylinder. To determine the end clearance, set the feeler gauges in between the ends of the ring until it comes to the correct gauge width where it runs with slight friction. If the gap is too small one can conveniently replace the rings without filing the end. End gap is not a factor unless it is greater than approximately 0.040-inch so double-check the rings for the engine. You should do this for every ring in the first cylinder and the remaining cylinders, always trying to pair them sufficiently: rings, pistons, cylinders. After that checks the gap of the ring end and adjustments needs to be made, the rings have to be fitted to the pistons, the first one is the oil control ring which comprises of three rings. Place the spacer/expander into the groove with the anti-rotation tang, if used, in position and then set the lower side rail in place; it is not necessary to use a piston ring installation tool at this time as it can damage the part. For the upper side rail do the same and make sure both can move freely in the grove. Subsequently, the middle ring which indeed has the identification mark facing upwards should be clipped in the same manner into the middle groove using the piston ring installation tool. Last, fit the top ring in the same manner and aligning the mark in upward position and similarly continue the process with all the pistons and rings.

Related Toyota 4Runner Parts

Browse by Year

2024 Piston Ring Set 2023 Piston Ring Set 2022 Piston Ring Set 2021 Piston Ring Set 2020 Piston Ring Set 2019 Piston Ring Set 2018 Piston Ring Set 2017 Piston Ring Set 2016 Piston Ring Set 2015 Piston Ring Set 2014 Piston Ring Set 2013 Piston Ring Set 2012 Piston Ring Set 2011 Piston Ring Set 2010 Piston Ring Set 2009 Piston Ring Set 2008 Piston Ring Set 2007 Piston Ring Set 2006 Piston Ring Set 2005 Piston Ring Set 2004 Piston Ring Set 2003 Piston Ring Set 2002 Piston Ring Set 2001 Piston Ring Set 2000 Piston Ring Set 1999 Piston Ring Set 1998 Piston Ring Set 1997 Piston Ring Set 1996 Piston Ring Set 1995 Piston Ring Set 1994 Piston Ring Set 1993 Piston Ring Set 1992 Piston Ring Set 1991 Piston Ring Set 1990 Piston Ring Set 1989 Piston Ring Set 1988 Piston Ring Set 1987 Piston Ring Set 1986 Piston Ring Set 1985 Piston Ring Set 1984 Piston Ring Set