My Garage

My Account

Cart

Genuine Toyota 4Runner Sway Bar Link

Stabilizer Sway Bar Link- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Sway Bar Links found

Toyota 4Runner Right Front Suspension Stabilizer Bar Link Kit

Part Number: 48820-60050$88.61 MSRP: $124.90You Save: $36.29 (30%)Ships in 1-3 Business DaysToyota 4Runner Left Front Suspension Stabilizer Bar Link Kit

Part Number: 48810-60040$88.61 MSRP: $124.90You Save: $36.29 (30%)Ships in 1-3 Business DaysToyota 4Runner Front Stabilizer Link Assembly

Part Number: 48820-35030$93.21 MSRP: $131.39You Save: $38.18 (30%)Ships in 1-3 Business DaysToyota 4Runner Rear Stabilizer Link Assembly, Driver Side

Part Number: 48830-60030$67.13 MSRP: $94.63You Save: $27.50 (30%)Ships in 1-3 Business DaysToyota 4Runner Rear Stabilizer Link Assembly

Part Number: 48830-35020$84.59 MSRP: $119.25You Save: $34.66 (30%)Ships in 1-3 Business DaysToyota 4Runner Rear Stabilizer Link Assembly

Part Number: 48830-35010$90.85 MSRP: $128.06You Save: $37.21 (30%)Toyota 4Runner Front Stabilizer Link Assembly

Part Number: 48820-35010$59.22 MSRP: $83.48You Save: $24.26 (30%)Toyota 4Runner Front Stabilizer Link Assembly

Part Number: 48820-60090$65.12 MSRP: $91.80You Save: $26.68 (30%)Ships in 1-3 Business DaysToyota 4Runner Rear Stabilizer Link Assembly

Part Number: 48830-60060$72.32 MSRP: $101.94You Save: $29.62 (30%)Ships in 1-3 Business Days

Toyota 4Runner Sway Bar Link

The Sway Bar Link is among those vital parts that distinctively enhance the steadiness as well as reliability of every Toyota 4Runner model. The Sway Bar Link is an essential component of the Toyota 4Runner as it is primarily responsible for linking the sway bar to the control arm in order to control body roll during cornering while on the different road types covering and keeping the passengers comfortable. This feature is very useful where drivers who consider safety and efficiency are involved since balances the distribution of the vehicle mass. Toyota 4Runner has been on the market since 1984 as a mid-size SUV. Moreover, the Sway Bar Link went through five generations to present an optimal level of suspension response in SR5, limited, and TRD Pro models. Successive models of the Sway Bar Link has been designed specially for smoother transfer of motion, which is somehow related to the smooth ride characteristic of Toyota 4Runner. Being highly resistant, the automotive spare part has carved a niche for the Toyota 4Runner Sway Bar Link to become a strong dealer in the automotive industry where it provides drivers with the necessary authority to pursue turns and bumpy roads. This role of handling multiple 4Runner models underlines its importance, and it is a crucial component of the vehicle's suspension. In conclusion, the Toyota 4Runner Sway Bar Link improves the driving performance while engaging the consumers and highly importantly, contributes to the safety and reliability that Toyota makes a point to offer.

If you are in demand for superior quality and affordable OEM Toyota 4Runner Sway Bar Link, then shop with us! We own a wide range of the reduced-priced genuine Toyota 4Runner Sway Bar Link. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota 4Runner Sway Bar Link Parts Questions & Experts Answers

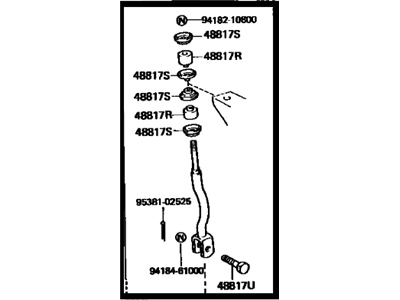

- Q: How to properly remove and inspect the rear Sway Bar Bushing,Sway Bar Kit and Sway Bar Link on 2003 through 2009 Toyota 4Runner?A:Lift the rear of the car and safely support it on jackstands; place chocks in front of the wheels to prevent the vehicle from moving. It is possible to pull out the nuts of sway bar link and both of links and to throw away the nuts with fastening the link on the frame. Next, the bushing bracket bolts and bracket must be removed to disconnect the sway bar from the rear axle, before noting the position of the bushing stopper on the sway bar though. Next, unbolt the sway bar and clean the Sway Bar Bushing of any dirt or debris; if any show signs of cracking, tearing or have significant signs of wear, then it's time for replacement. Looseness of the balljoint on the lower end of each link or the existence of any sign of excessive wear should be checked on the link and suspension setup test by turning the balljoint with an inch-pound torque wrench and comparing the rotational torque to the specified value. When fitting the new rubber bushings in the location where the sway bar was, place the bushing stopper against them. Removal is carried out in the reverse sequence, after which a new link-to-frame nut should be applied, and all the fastenings should be tightened to the specified torque.

Related Toyota 4Runner Parts

Browse by Year

2024 Sway Bar Link 2023 Sway Bar Link 2022 Sway Bar Link 2021 Sway Bar Link 2020 Sway Bar Link 2019 Sway Bar Link 2018 Sway Bar Link 2017 Sway Bar Link 2016 Sway Bar Link 2015 Sway Bar Link 2014 Sway Bar Link 2013 Sway Bar Link 2012 Sway Bar Link 2011 Sway Bar Link 2010 Sway Bar Link 2009 Sway Bar Link 2008 Sway Bar Link 2007 Sway Bar Link 2006 Sway Bar Link 2005 Sway Bar Link 2004 Sway Bar Link 2003 Sway Bar Link 2002 Sway Bar Link 2001 Sway Bar Link 2000 Sway Bar Link 1999 Sway Bar Link 1998 Sway Bar Link 1997 Sway Bar Link 1996 Sway Bar Link 1995 Sway Bar Link 1994 Sway Bar Link 1993 Sway Bar Link 1992 Sway Bar Link 1991 Sway Bar Link 1990 Sway Bar Link 1989 Sway Bar Link 1988 Sway Bar Link 1987 Sway Bar Link 1986 Sway Bar Link 1985 Sway Bar Link