My Garage

My Account

Cart

Genuine Toyota Celica ABS Control Module

Anti Lock Brake Control Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 ABS Control Modules found

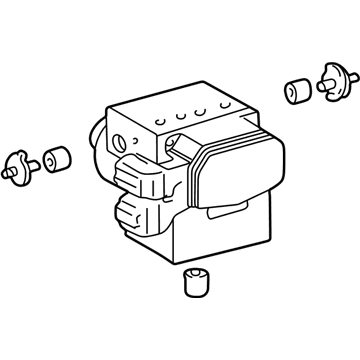

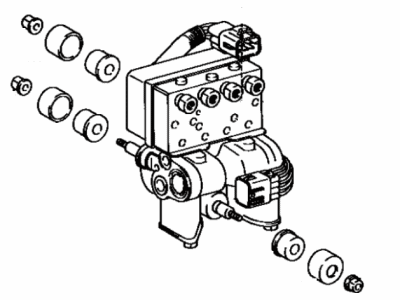

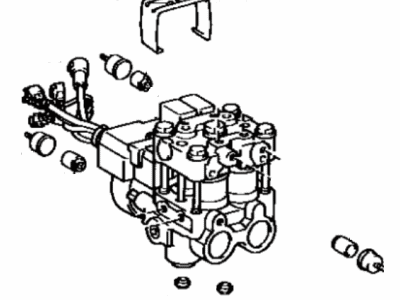

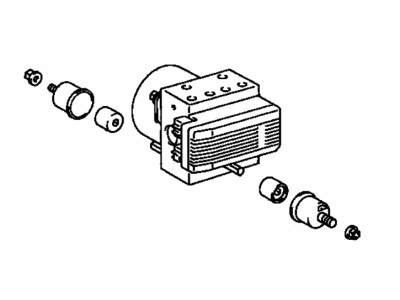

Toyota Celica Brake Actuator Assembly

Part Number: 44050-20110$623.82 MSRP: $800.06You Save: $176.24 (23%)Ships in 1-3 Business DaysToyota Celica Skid Control Computer Assembly

Part Number: 89540-20460$289.78 MSRP: $356.92You Save: $67.14 (19%)Ships in 1-3 Business DaysToyota Celica Brake Actuator Assembly

Part Number: 44510-20140$707.11 MSRP: $906.90You Save: $199.79 (23%)Ships in 1-3 Business DaysToyota Celica Brake Actuator Assembly

Part Number: 44510-20160$1206.93 MSRP: $1547.94You Save: $341.01 (23%)Ships in 1-3 Business DaysToyota Celica Skid Control Computer Assembly

Part Number: 89540-20461$289.78 MSRP: $356.92You Save: $67.14 (19%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

Toyota Celica ABS Control Module

If you are in demand for superior quality and affordable OEM Toyota Celica ABS Control Module, then shop with us! We own a wide range of the reduced-priced genuine Toyota Celica ABS Control Module. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Celica ABS Control Module Parts Questions & Experts Answers

- Q: What is the purpose of the anti-lock brake system,ABS Control Module and Speed Sensor on Toyota Celica?A:The anti-lock brake system, introduced in 1988, is designed to maintain vehicle steerability, directional stability, and optimum deceleration under severe braking conditions and on various road surfaces by monitoring the rotational speed of each wheel and controlling brake line pressure to prevent wheel lock-up. The actuator assembly includes the master cylinder, an electric hydraulic pump, and four solenoid valves, with the pump providing hydraulic pressure to charge the reservoirs that supply pressure to the braking system. Speed sensors located at each wheel generate electrical pulsations to indicate wheel rotational speed, with front sensors mounted to the brake backing plates on 1988 and 1989 models, while later models have sensor rings integrated with the outer Constant Velocity joint. Rear wheel sensors are bolted to the brake backing plates or axle carriers, with sensor rings integral to the rear hub assemblies. The ABS computer, mounted under the dashboard for earlier models and in the luggage compartment for later ones, processes information from the wheel speed sensors to control hydraulic line pressure and prevent wheel lock-up, while also monitoring the system for faults. If a problem arises, an "ANTI-LOCK" or "ABS" light will illuminate on the dashboard, and a diagnostic code will be stored for retrieval by a service technician. If the dashboard warning light remains on during operation, the ABS system needs attention, and while a special electronic ABS diagnostic tester is required for proper diagnosis, preliminary checks such as verifying brake fluid level, ensuring electrical connectors are secure, and checking fuses can be performed by a home mechanic before seeking professional repair.

Related Toyota Celica Parts

Browse by Year

2005 ABS Control Module 2004 ABS Control Module 2003 ABS Control Module 2002 ABS Control Module 2001 ABS Control Module 2000 ABS Control Module 1999 ABS Control Module 1998 ABS Control Module 1997 ABS Control Module 1996 ABS Control Module 1995 ABS Control Module 1994 ABS Control Module 1993 ABS Control Module 1992 ABS Control Module 1991 ABS Control Module 1990 ABS Control Module 1989 ABS Control Module 1988 ABS Control Module