My Garage

My Account

Cart

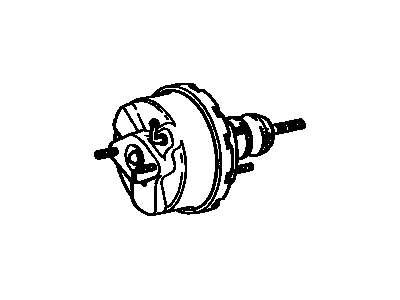

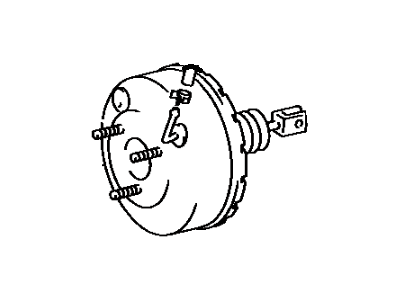

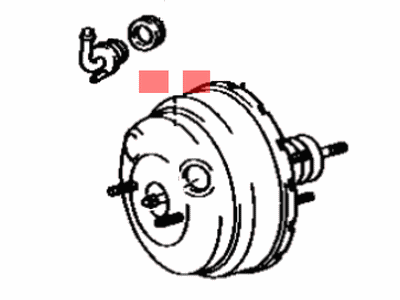

Genuine Toyota Celica Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

38 Brake Boosters found

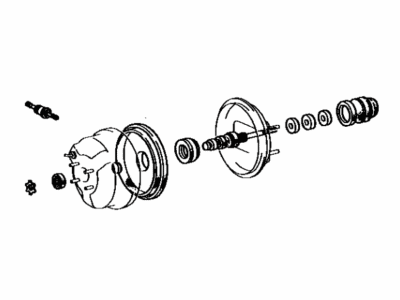

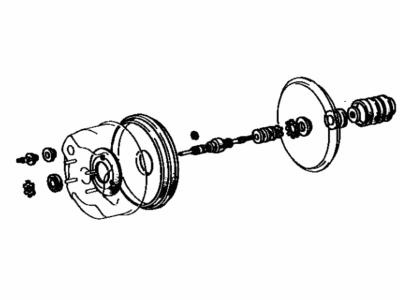

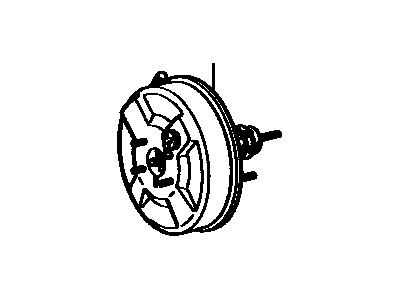

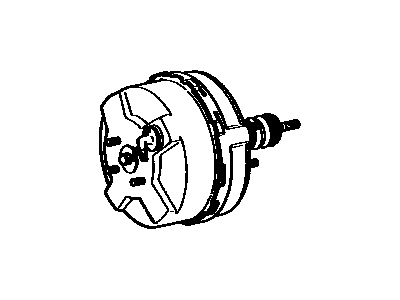

Toyota Celica Brake Booster Assembly

Part Number: 44610-2G080$618.87 MSRP: $924.06You Save: $305.19 (34%)Ships in 1-3 Business DaysToyota Celica Brake Booster Assembly

Part Number: 44610-2G040$542.02 MSRP: $809.30You Save: $267.28 (34%)Ships in 1-3 Business DaysToyota Celica Brake Booster Assembly

Part Number: 44610-2B600$552.32 MSRP: $824.69You Save: $272.37 (34%)Ships in 1-3 Business DaysToyota Celica Brake Booster Assembly

Part Number: 44610-2B620$574.73 MSRP: $858.16You Save: $283.43 (34%)Ships in 1-3 Business DaysToyota Celica Brake Booster Assembly

Part Number: 44610-2G020$618.87 MSRP: $924.06You Save: $305.19 (34%)Ships in 1-3 Business DaysToyota Celica Brake Booster Assembly

Part Number: 44610-2D590$760.46 MSRP: $1135.47You Save: $375.01 (34%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 38 Results

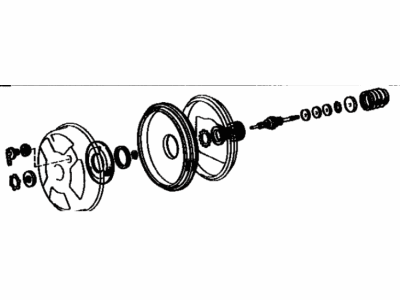

Toyota Celica Brake Booster

The detail fitted Brake Booster is quite important because it improves the level of braking system of Toyota Celica cars, providing safer road use. Well established for its effectiveness and durability, the product diminishes the load on the driver, making the brake much smoother and responsive. It can use either vacuum or hydraulic power, single or dual diaphragm, and depending on the model, there are various designs to suit it. Greater diameter boosters offer greater power aided, and hence the dual diaphragm choice offers small, efficient packaging, perfect for custom installations. Compatibility demonstrates that the Brake Booster is a universal part of Toyota Celica models ranging from the first generation in 1970 up to the final production in 2006, as well as disc and drum braking systems. This characteristic not only improves productivity but is also effective in increasing the safety of the vehicle. Other attributes make the Brake Booster stand out in the auto market, including the phase-regulation system that was launched in late 1997. The sporty design and robust power of the Toyota Celica make it possible for it to retain its place as one of the standout models, and the Brake Booster helps it retain that tradition. All in all, the Brake Booster is a perfect example of the cars' manufacturer-noted quality and advanced features that set Toyota Celica in a league apart from the others.

If you are in demand for superior quality and affordable OEM Toyota Celica Brake Booster, then shop with us! We own a wide range of the reduced-priced genuine Toyota Celica Brake Booster. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Celica Brake Booster Parts Questions & Experts Answers

- Q: How to operate, check, remove, and install a power brake booster on Toyota Celica?A:To perform an operating check, depress the brake pedal several times with the engine off, ensuring no change in the pedal reserve distance. Start the engine while depressing the pedal; a slight drop indicates normal operation. For an airtightness check, start the engine and turn it off after one or two minutes, then slowly depress the brake pedal several times; if the pedal depresses less each time, the booster is airtight. While the engine runs, depress the brake pedal, then stop the engine with the pedal held down; if there's no change in pedal reserve travel after 30 seconds, the booster is airtight. Power brake booster units should not be disassembled due to their complexity and critical role in brake performance; they should be replaced with new or rebuilt units. To remove the booster, first remove the Brake Master Cylinder, then take out the left side under-dash panel to access the pushrod clevis connecting the booster to the brake pedal. Remove the clevis pin retaining clip and pull out the pin, then unscrew the locknut to loosen the clevis. Disconnect the hose from the engine to the booster, taking care not to damage it, and remove the four nuts and washers securing the brake booster to the firewall. Slide the booster straight out until the studs clear the holes. For installation, follow the reverse of removal, tightening the clevis locknut and booster mounting nuts to the specified torque. If replacing the power booster unit, measure and adjust the clearance between the master cylinder piston and the pushrod in the vacuum booster as necessary, ensuring no clearance or interference exists. Finally, after installing the master cylinder and brake hoses, adjust the brake pedal height and freeplay, and bleed the system.

Related Toyota Celica Parts

Browse by Year

2005 Brake Booster 2004 Brake Booster 2003 Brake Booster 2002 Brake Booster 2001 Brake Booster 2000 Brake Booster 1999 Brake Booster 1998 Brake Booster 1997 Brake Booster 1996 Brake Booster 1995 Brake Booster 1994 Brake Booster 1993 Brake Booster 1992 Brake Booster 1991 Brake Booster 1990 Brake Booster 1989 Brake Booster 1988 Brake Booster 1987 Brake Booster 1986 Brake Booster 1985 Brake Booster 1984 Brake Booster 1983 Brake Booster 1982 Brake Booster 1981 Brake Booster 1980 Brake Booster 1979 Brake Booster 1978 Brake Booster