My Garage

My Account

Cart

Genuine Toyota Celica Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

47 Clutch Discs found

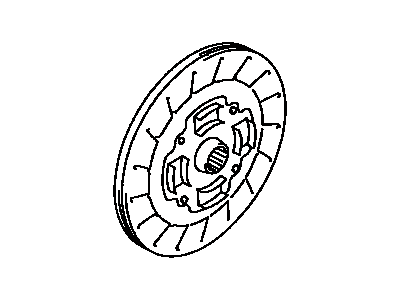

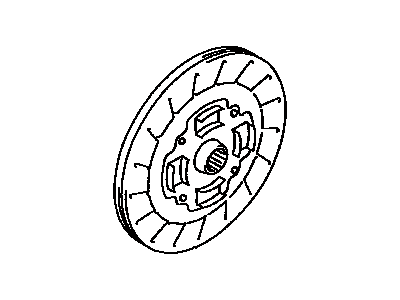

Toyota Celica Clutch Disc Assembly

Part Number: 31250-12360$46.87 MSRP: $65.64You Save: $18.77 (29%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-17040$122.02 MSRP: $173.47You Save: $51.45 (30%)Ships in 1-2 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-14130$131.73 MSRP: $187.28You Save: $55.55 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc

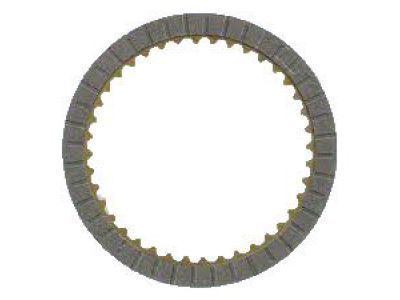

Part Number: 35633-52020$39.00 MSRP: $54.51You Save: $15.51 (29%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-20180$122.02 MSRP: $173.47You Save: $51.45 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-20250$122.02 MSRP: $173.47You Save: $51.45 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-17050$173.85 MSRP: $247.16You Save: $73.31 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-20340$96.51 MSRP: $136.05You Save: $39.54 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-20170$61.67 MSRP: $87.11You Save: $25.44 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-17051$173.85 MSRP: $247.16You Save: $73.31 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-30140$90.57 MSRP: $127.67You Save: $37.10 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-30200$123.69 MSRP: $175.86You Save: $52.17 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-30210$37.06 MSRP: $54.94You Save: $17.88 (33%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-30211$37.06 MSRP: $54.94You Save: $17.88 (33%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-20330$209.83 MSRP: $300.88You Save: $91.05 (31%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-20331$209.83 MSRP: $300.88You Save: $91.05 (31%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-20140$61.67 MSRP: $87.11You Save: $25.44 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-14070$90.57 MSRP: $127.67You Save: $37.10 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-14071$90.57 MSRP: $127.67You Save: $37.10 (30%)Ships in 1-3 Business DaysToyota Celica Clutch Disc Assembly

Part Number: 31250-14072$90.57 MSRP: $127.67You Save: $37.10 (30%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 47 Results

Toyota Celica Clutch Disc

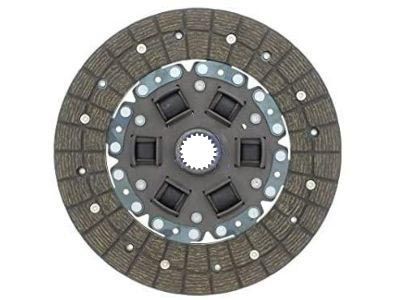

The Clutch Disc in Toyota Celica vehicles plays an essential part in coupling the engine to the input shaft of the transmission for smooth shifting of the gears. It comprises friction materials on both sides that come in contact with the flywheel and pressure plate to transmit power from the engine. The pressure plate unwinds from the Toyota Clutch Disc when the clutch pedal is pressed enabling gear changes. A mixture of types such as organic, ceramic, and more advanced ones e.g. sintered iron has been applied. Organic Celica Clutch Disc are available for normal driving and more specific ceramic and kevlar for performance uses, with higher heat and strength. The design may incorporate a sprung hub, which helps absorb the shock and smoothen the functioning. Finally, the cruciality of the Toyota Celica Clutch Disc cannot be overstated regarding the consistency of the vehicles' functioning and needs to be regularly replaced prior to slippage and damage.

If you are in demand for superior quality and affordable OEM Toyota Celica Clutch Disc, then shop with us! We own a wide range of the reduced-priced genuine Toyota Celica Clutch Disc. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Celica Clutch Disc Parts Questions & Experts Answers

- Q: How to remove the Clutch Disc and Pressure Plate on Toyota Celica?A:The major components of the clutch are accessed by having to remove the transaxle but the engine remains in the vehicle. If major overhauling of the engine is to be done, then clutch should also be inspected and worn out part should be replaced because they are cheap in cost but may be so difficult to remove once the engine is taken off. The release cylinder has to be detached and shifted aside and the hose does not need to be disconnected from the release cylinder. The transaxle needs to be pulled out of the car and the engine needs to be properly supported usually on an engine lift. In all the mentioned configurations, it is indicated that the release fork and bearing can continue to remain incorporate with the transaxle. For enhancing the hold of the clutch disc during such processes like its removal, one should intend to insert a clutch alignment tool through the clutch disc hub. Check for indexing marks on the flywheel and on the pressure plate, reading these if there are any, otherwise create your own for reference when you are re-fitting them. Relieve spring pressure on the pressure plate to the flywheel by slackening the bolts in diagonal fashion and then taking out the bolts, the pressure plate and clutch disc. It is recommended to check every part of the unit but, at least, the flywheel needs to be examined for its cracks and damages, and the clutch disc lining for wears. The Release Bearing should also be replaced together with the clutch disc. Pressure plate should be examined for score marks and overheating and if they are the situation rectified than pressure plate should be changed. For optimum performance it is recommended that the flywheel and pressure plate contact surfaces be clean, free from any oil or grease. Before tightening up the bolts, align the clutch disc and pressure plate using an alignment tool in a correct manner. Before final tightening of the pressure plate-to-flywheel bolts, they should be tightened just enough to create slightly snug fit and at this stage, the clutch disc should be set symmetrically so as to balance it before the bolts are tight, they are tightened in a bolt star pattern while avoiding the ring wrench technique which could cause a distortion of the clutch disc. When tightening all the bolts, it is important to take out the adjustment tool and then apply grease on the interior part of the releasable bearing and all contacts. Last but not the least fit the clutch release bearing, the transaxle, the release cylinder and all other parts removed in this process should then be adequately tightened according to the recommended torque settings.

Related Toyota Celica Parts

Browse by Year

2005 Clutch Disc 2004 Clutch Disc 2003 Clutch Disc 2002 Clutch Disc 2001 Clutch Disc 2000 Clutch Disc 1999 Clutch Disc 1998 Clutch Disc 1997 Clutch Disc 1996 Clutch Disc 1995 Clutch Disc 1994 Clutch Disc 1993 Clutch Disc 1992 Clutch Disc 1991 Clutch Disc 1990 Clutch Disc 1989 Clutch Disc 1988 Clutch Disc 1987 Clutch Disc 1986 Clutch Disc 1985 Clutch Disc 1984 Clutch Disc 1983 Clutch Disc 1982 Clutch Disc 1981 Clutch Disc 1980 Clutch Disc 1979 Clutch Disc 1978 Clutch Disc