My Garage

My Account

Cart

Genuine Toyota Corolla Steering Knuckle

Front Steering Knuckle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

50 Steering Knuckles found

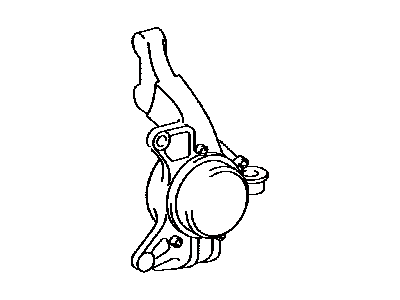

Toyota Corolla Steering Knuckle Left Hand

Part Number: 43212-02220$244.28 MSRP: $350.28You Save: $106.00 (31%)Ships in 1-2 Business DaysToyota Corolla Steering Knuckle Right Hand

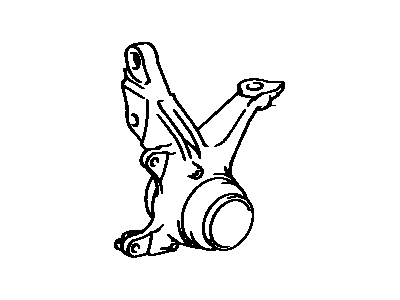

Part Number: 43211-02220$241.85 MSRP: $346.79You Save: $104.94 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

Part Number: 43212-02390$236.74 MSRP: $339.47You Save: $102.73 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

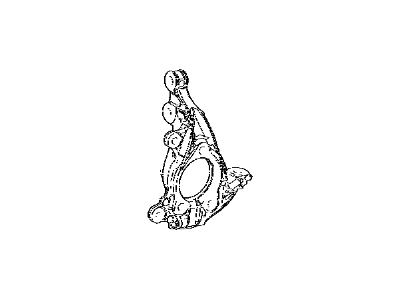

Part Number: 43212-19015$283.26 MSRP: $406.18You Save: $122.92 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-12420$275.84 MSRP: $395.53You Save: $119.69 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

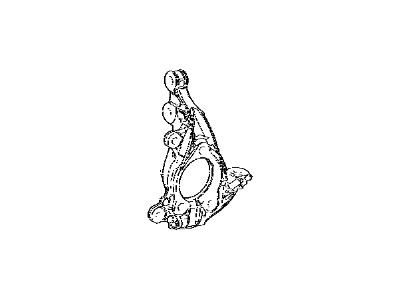

Part Number: 43211-47040$236.74 MSRP: $339.47You Save: $102.73 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-19015$283.26 MSRP: $406.18You Save: $122.92 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

Part Number: 43212-47040$236.74 MSRP: $339.47You Save: $102.73 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-02390$236.74 MSRP: $339.47You Save: $102.73 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-12490$241.85 MSRP: $346.79You Save: $104.94 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

Part Number: 43212-12440$244.28 MSRP: $350.28You Save: $106.00 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

Part Number: 43212-12380$262.38 MSRP: $376.24You Save: $113.86 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

Part Number: 43212-12390$275.84 MSRP: $395.53You Save: $119.69 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-12430$275.84 MSRP: $395.53You Save: $119.69 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-12230$217.88 MSRP: $312.44You Save: $94.56 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

Part Number: 43212-12190$217.88 MSRP: $312.44You Save: $94.56 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-12440$262.38 MSRP: $376.24You Save: $113.86 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Right Hand

Part Number: 43211-12220$259.83 MSRP: $372.57You Save: $112.74 (31%)Ships in 1-3 Business DaysToyota Corolla Steering Knuckle Left Hand

Part Number: 43212-12180$259.83 MSRP: $372.57You Save: $112.74 (31%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 50 Results

Toyota Corolla Steering Knuckle

If you are in demand for superior quality and affordable OEM Toyota Corolla Steering Knuckle, then shop with us! We own a wide range of the reduced-priced genuine Toyota Corolla Steering Knuckle. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Corolla Steering Knuckle Parts Questions & Experts Answers

- Q: How to remove and install the steering knuckle on Toyota Corolla?A:To remove the wheel, first loosen the lug nuts, raise the vehicle, and support it securely on jackstands before taking off the wheel. Next, remove the brake caliper without disconnecting the hose, followed by the brake disc, and disconnect the brake hose from the strut, ensuring the caliper is hung from the coil spring with wire to avoid strain on the hose. If the vehicle has ABS, disconnect and remove the wheel speed sensor. Mark the relationship of the strut to the steering knuckle, then loosen the strut-to-steering knuckle nuts and bolts without removing them. Separate the tie-rod end from the steering knuckle arm, then remove the balljoint-to-lower arm bolt and nuts, prying the Control Arm and balljoint apart with a large prybar or screwdriver. Remove the driveaxle/hub nut and push the driveaxle from the hub, supporting its end with wire. If the axle is out, use a balljoint removal tool or small puller to detach the balljoint from the steering knuckle, noting that if the balljoint is in good condition, it can remain attached when replacing the hub bearings. Remove the strut-to-knuckle bolts and carefully separate the steering knuckle from the strut. For installation, guide the knuckle and hub assembly into position, inserting the driveaxle into the hub. Push the knuckle into the strut flange and install the bolts and nuts without tightening them yet. If the balljoint was removed from the old knuckle and is to be used with the new one, connect it to the knuckle and tighten the balljoint stud nut, installing a new cotter pin. Attach the balljoint to the control arm without tightening the bolt and nuts yet, then attach the tie-rod to the steering knuckle arm. Tighten the strut bolt nuts, the balljoint-to-control arm bolt and nuts, and the tie-rod nut to the specified torque. Place the brake disc on the hub and install the caliper as previously outlined. Install the driveaxle/hub nut and tighten it to the specified torque, then install the wheel and lug nuts. Lower the vehicle and tighten the lug nuts to the specified torque, and finally, have the front-end alignment checked and adjusted if necessary.

Related Toyota Corolla Parts

Browse by Year

2024 Steering Knuckle 2023 Steering Knuckle 2022 Steering Knuckle 2021 Steering Knuckle 2020 Steering Knuckle 2019 Steering Knuckle 2018 Steering Knuckle 2017 Steering Knuckle 2016 Steering Knuckle 2015 Steering Knuckle 2014 Steering Knuckle 2013 Steering Knuckle 2012 Steering Knuckle 2011 Steering Knuckle 2010 Steering Knuckle 2009 Steering Knuckle 2008 Steering Knuckle 2007 Steering Knuckle 2006 Steering Knuckle 2005 Steering Knuckle 2004 Steering Knuckle 2003 Steering Knuckle 2002 Steering Knuckle 2001 Steering Knuckle 2000 Steering Knuckle 1999 Steering Knuckle 1998 Steering Knuckle 1997 Steering Knuckle 1996 Steering Knuckle 1995 Steering Knuckle 1994 Steering Knuckle 1993 Steering Knuckle 1992 Steering Knuckle 1991 Steering Knuckle 1990 Steering Knuckle 1989 Steering Knuckle 1988 Steering Knuckle 1987 Steering Knuckle 1986 Steering Knuckle 1985 Steering Knuckle 1984 Steering Knuckle