My Garage

My Account

Cart

Genuine Toyota Echo Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Calipers found

Toyota Echo Front Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-52010$238.75 MSRP: $342.35You Save: $103.60 (31%)Ships in 1-3 Business DaysToyota Echo Disc Brake Cylinder Assembly Left Hand

Part Number: 47750-52010$238.75 MSRP: $342.35You Save: $103.60 (31%)Ships in 1-3 Business DaysToyota Echo Disc Brake Cylinder Assembly Left Hand

Part Number: 47750-52020$172.80 MSRP: $245.66You Save: $72.86 (30%)Ships in 1-3 Business DaysToyota Echo Front Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-52020$172.80 MSRP: $245.66You Save: $72.86 (30%)Ships in 1-3 Business Days

Toyota Echo Brake Caliper

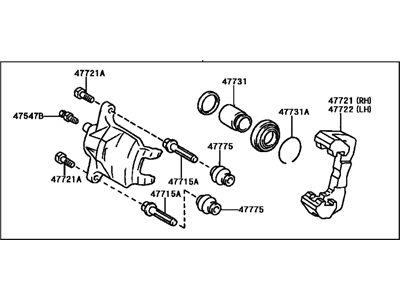

Toyota Echo Brake Caliper is one of the major and essential parts of braking system in those cars which are more famous for their performance and reliability. This Brake Caliper is one that transmits hydraulic pressure coming from the master cylinder to a mechanical force that applied the brake pad to engage the rotor to stop the vehicle promptly. Some of the TS models applied in Toyota Echo incorporate both the fixed as well as the floating Brake Caliper while in their manufacturing process. Fixed caliper provide accurate pressure for multiple pistons whereas floating caliper is a more flexible design. Since this Brake Caliper belongs to Toyota Echo, it is made of cast iron and the piston can be made of steel or phenolic. Proper servicing of the Brake Caliper is critical to avoid various problems as the brake drag or fluid leaks improving both performance and security. Toyota's Echo or as it is called in some markets, the platz or Yaris was targeted at young people seeking affordable vehicles, the cars' Brake Caliper is a rather important factor affecting the vehicle's performance. The Toyota Echo Brake Caliper comes in several choices for single-piston to the new generation multi-piston configuration that makes it quite noticeable in today's automotive industry due to its better stopping power and reliability. After the Toyota Echo was discontinued in the market in 2005, the caliper continues to be associated with efficiency and reliability within the market among the Echo consumers.

If you are in demand for superior quality and affordable OEM Toyota Echo Brake Caliper, then shop with us! We own a wide range of the reduced-priced genuine Toyota Echo Brake Caliper. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Echo Brake Caliper Parts Questions & Experts Answers

- Q: How to remove, overhaul, and refitting of a front brake caliper on Toyota Echo?A:To replace the brake caliper; first, engage the handbrake tighten the front wheel nuts; jack up the front part of the car and put it on some stands; then, take off the right front wheel, which is at the appropriate side where the caliper was damaged. Further, if the caliper is to be fully removed, tighten a brake hose clamp to the flexible hose to prevent leakage of brake fluids, then unscrew the Banjo bolt holding the brake hose and get the copper washers as well. Screw the free ends of the hydraulic unions in the caliper and hose to seal against dust and dirt, and then pull out the brake pads. Using the spanner, loosen the upper guide pin bolt to be able to take out the upper guide pin so as to have the caliper off the mounting bracket. If only unbolting, support the caliper with wire, string, or a cable-tie from a suitable location beneath the wheel arch and make sure that it is not hanging off the flexible hose only. In the unlikely, lose the caliper carrier bracket from the hub carrier if possible. Regarding the overhauling, a rider must understand that the aluminium cylinder bore cannot be honed and if the scoring is apparent, the rider will need to press a stainless steel sleeve together with a new piston. Because of the cost, overhauling is relatively less cost-effective compared with replacing the caliper with a new or rebuilt one that comes with warranty Guarantee, the overhaul process, therefore, is not described. To refit reverse the operations of removing and again check that the flexible brake hose is not twisted while tightening the mounting bolts and wheel nuts to the correct torque. Released pressure in the brake circuit, and unclamped the brake hose, and see if there are any signs of leakage that may have originated from the hose connections when testing the brakes.