My Garage

My Account

Cart

Genuine Toyota Highlander ABS Control Module

Anti Lock Brake Control Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

44 ABS Control Modules found

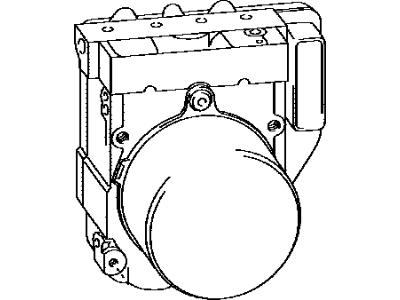

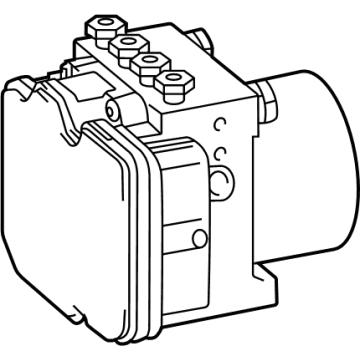

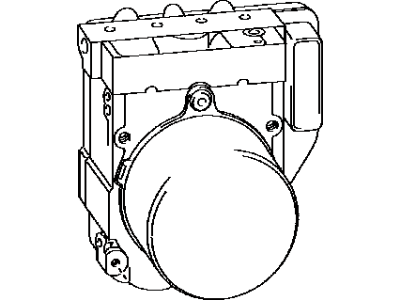

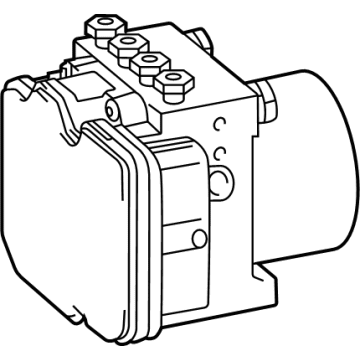

Toyota Highlander Brake Actuator Assembly

Part Number: 44050-48320$1213.47 MSRP: $1556.32You Save: $342.85 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-48190$1377.90 MSRP: $2057.39You Save: $679.49 (34%)Ships in 1-2 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-48120$966.72 MSRP: $1239.85You Save: $273.13 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0E161$1037.79 MSRP: $1331.00You Save: $293.21 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-48A30$938.20 MSRP: $1203.28You Save: $265.08 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly with Fluid

Part Number: 44050-48110$966.72 MSRP: $1239.85You Save: $273.13 (23%)Toyota Highlander Brake Actuator Assembly

Part Number: 44050-0E160$969.28 MSRP: $1243.14You Save: $273.86 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0E300$987.22 MSRP: $1266.14You Save: $278.92 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0E130$1035.12 MSRP: $1327.58You Save: $292.46 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0E180$947.78 MSRP: $1215.57You Save: $267.79 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0E330$947.78 MSRP: $1215.57You Save: $267.79 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0E340$956.69 MSRP: $1226.99You Save: $270.30 (23%)Ships in 1-3 Business DaysToyota Highlander ACTUATOR Assembly, Brake

Part Number: 44050-0E151$1037.79 MSRP: $1331.00You Save: $293.21 (23%)Toyota Highlander Skid Control Computer Assembly

Part Number: 89540-48360$2196.65 MSRP: $2817.29You Save: $620.64 (23%)Ships in 1-3 Business DaysToyota Highlander Skid Control Computer Assembly

Part Number: 89540-48190$406.22 MSRP: $520.53You Save: $114.31 (22%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0E781$839.72 MSRP: $1076.97You Save: $237.25 (23%)Ships in 1-2 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-48340$1211.80 MSRP: $1554.18You Save: $342.38 (23%)Ships in 1-3 Business DaysToyota Highlander Computer Assembly, Skid Control

Part Number: 89540-48460$2335.60 MSRP: $2995.49You Save: $659.89 (23%)Ships in 1-3 Business DaysToyota Highlander Brake Actuator Assembly

Part Number: 44050-0EA20$940.32 MSRP: $1205.99You Save: $265.67 (23%)Ships in 1-2 Business DaysToyota Highlander Actuator Assembly, Brake

Part Number: 44050-48030$778.12 MSRP: $997.97You Save: $219.85 (23%)

| Page 1 of 3 |Next >

1-20 of 44 Results

Toyota Highlander ABS Control Module

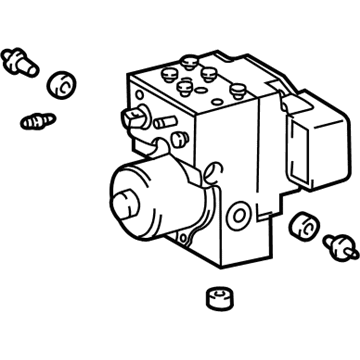

Extremely important for the proper functioning of the car, the Toyota Highlander ABS Control Module is an element of the anti-lock brake system and is known to offer great results in numerous Highlander models. This block is important for improving vehicle safety since it helps avoid the lock-up of the wheels during very vigorous braking and helps maintain necessary control to avoid skidding. Anti-lock brake system is accompanied in the Toyota Highlander ABS Control Module by other sophisticated options like electronic stability control (ESC) and traction control, which enhance control in the manner that brakes some of the wheels and controls the amount of brake force during acceleration. This flexibility serves to balance numerous driving circumstances and therefore keeps the Toyota Highlander as a reliable car for families and other users. All the three-row SUVs, five and seven-traveler available with either front-wheel or all-wheel drive, makes Toyota Highlander suitable for various terrains. The technological features such as wheel speed sensors and electronic control unit (ECU) integrated in the ABS Control Module help to improve efficiency and safety of vehicles stepping up the brand's recognition in automotive industry. However, one cannot help but notice the Toyota Highlander ABS Control Module since it is one of the optimal modules designed to work with the car's systems. Therefore, the vehicle is still a favorite among drivers who want a safe, efficient, and powerful SUV and the mentioned part, ABS Control Module, is one of the key elements that contribute to the vehicle's success.

If you are in demand for superior quality and affordable OEM Toyota Highlander ABS Control Module, then shop with us! We own a wide range of the reduced-priced genuine Toyota Highlander ABS Control Module. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Highlander ABS Control Module Parts Questions & Experts Answers

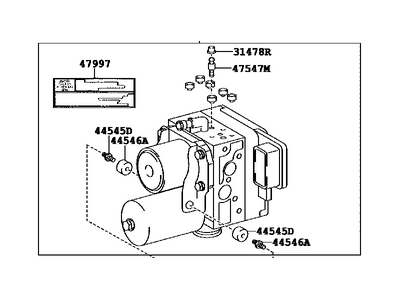

- Q: What is the purpose of the Anti-lock Brake System (ABS),ABS Control Module and Speed Sensor on Toyota Highlander?A:The Anti-lock Brake System (ABS) is designed to maintain vehicle steer ability, directional stability, and optimum deceleration under severe braking conditions and on most road surfaces. It does so by monitoring the rotational speed of each wheel and controlling the brake line pressure to prevent wheel lockup. The ABS system shares information with other optional systems, such as Electronic Brakeforce Distribution (EBO), Trac, and Vehicle Skid Control (VSC), to control vehicle handling. The actuator assembly, consisting of an electric hydraulic pump and solenoid valves, is responsible for providing hydraulic pressure and modulating brake line pressure. Speed sensors located at each wheel generate electrical pulsations indicating wheel rotational speed. The ABS computer processes information from the wheel speed sensors to control hydraulic line pressure and constantly monitors the system for faults. If a warning light comes on, preliminary checks can be performed, such as checking brake fluid level, verifying electrical connectors, checking fuses, and inspecting wiring connections. If the problem persists, the vehicle should be diagnosed and repaired by a qualified technician. Wheel speed sensors can be removed and installed by loosening lug nuts, raising the vehicle, disconnecting the electrical connector, removing the mounting bolt, and carefully pulling out the sensor. Installation is the reverse of the removal procedure.

Related Toyota Highlander Parts

Browse by Year

2024 ABS Control Module 2023 ABS Control Module 2022 ABS Control Module 2021 ABS Control Module 2020 ABS Control Module 2019 ABS Control Module 2018 ABS Control Module 2017 ABS Control Module 2016 ABS Control Module 2015 ABS Control Module 2014 ABS Control Module 2013 ABS Control Module 2012 ABS Control Module 2011 ABS Control Module 2010 ABS Control Module 2009 ABS Control Module 2008 ABS Control Module 2007 ABS Control Module 2006 ABS Control Module 2005 ABS Control Module 2004 ABS Control Module 2003 ABS Control Module 2002 ABS Control Module 2001 ABS Control Module