My Garage

My Account

Cart

Genuine Toyota Highlander Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Ball Joints found

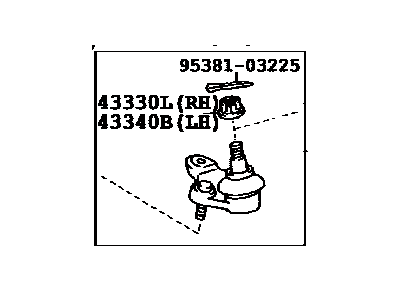

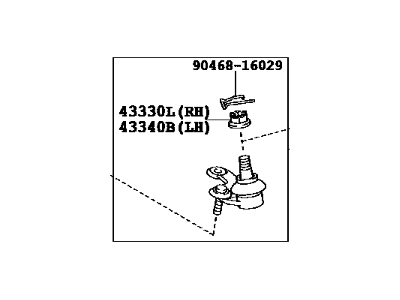

Toyota Highlander Front Upper Right Suspension Ball Joint Assembly

Part Number: 43330-09780$73.50 MSRP: $103.61You Save: $30.11 (30%)Ships in 1-3 Business DaysToyota Highlander Front Upper Left Suspension Ball Joint Assembly

Part Number: 43340-09140$72.91 MSRP: $102.78You Save: $29.87 (30%)Ships in 1-3 Business DaysToyota Highlander Front Upper Left Suspension Ball Joint Assembly

Part Number: 43340-49035$63.12 MSRP: $88.98You Save: $25.86 (30%)Ships in 1-2 Business DaysToyota Highlander Front Upper Right Suspension Ball Joint Assembly

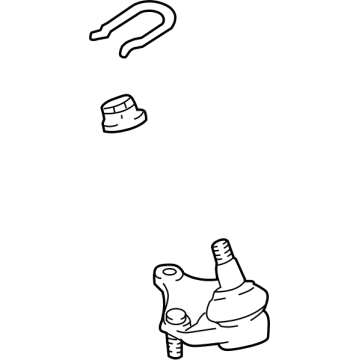

Part Number: 43330-49165$69.37 MSRP: $97.79You Save: $28.42 (30%)Ships in 1-2 Business DaysToyota Highlander Lower Ball Joint Assembly

Part Number: 43330-09B60$62.65 MSRP: $88.31You Save: $25.66 (30%)Ships in 1-3 Business DaysToyota Highlander Lower Ball Joint Assembly Front Right

Part Number: 43330-29405$68.66 MSRP: $96.79You Save: $28.13 (30%)Ships in 1-2 Business DaysToyota Highlander Front Upper Left Suspension Ball Joint Assembly

Part Number: 43340-29175$68.66 MSRP: $96.79You Save: $28.13 (30%)Ships in 1-2 Business DaysToyota Highlander Lower Ball Joint Assembly Front Right

Part Number: 43330-49125$69.37 MSRP: $97.79You Save: $28.42 (30%)Ships in 1-2 Business DaysToyota Highlander Front Upper Left Suspension Ball Joint Assembly

Part Number: 43340-49015$63.12 MSRP: $88.98You Save: $25.86 (30%)Ships in 1-2 Business Days

Toyota Highlander Ball Joint

If you are in demand for superior quality and affordable OEM Toyota Highlander Ball Joint, then shop with us! We own a wide range of the reduced-priced genuine Toyota Highlander Ball Joint. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Highlander Ball Joint Parts Questions & Experts Answers

- Q: How to Remove and Install a Ball Joint Using the Picklefork and Puller Methods on a Toyota Highlander?A:It is recommended that the wheel lug nuts be loosened, the car raised and supported on jack stands before the wheel is removed. If intending to use a puller for the balljoint, then it is advisable to slacken the driveaxle/hub nut before lifting the car. First, make sure to provide a ball joint stud, then, to eliminate the cotter pin and then, unscrew the nut halfway but not more. Disengage the ball joint from the Steering Knuckle with the use of the picklefork-type ball joint separator after which remove the ball joint stud nut. After that, remove the bolt and nuts used to fix the ball joint to the Control Arm, then use the pry bar to disengage ball joint from the control arm. When fitting stick the new balljoint into position on the steering knuckle and thread on the nut but do not over tighten it at this stage. Fix the ball joint to the control arm, next put in the bolt and nuts then tighten the nuts to the recommended torque. The balljoint stud nut should then be tightened to the required torque and a new cotter pin be fitted with the hole in the cotter pin engaging the slots on the nut; if not align the nut by tightening it without loosening it. Bolt the wheel and the lug nuts back in place, raise the vehicle and then tighten the lug nuts to the required measure. Where the puller method is applied, if used to removed the wheel speed sensor, and then loosen and unbolt the control arm to ball-joint and further unfasten the outer part of the driveaxle from the steering knuckle and suspend with a wire. Again unbolt the cotter pin and the nut, after which, use a small puller and place it over the ball joint stud and pull it to detach it from the steering knuckle Thus; remove the nut and the ball joint. Replace the new ball joints into the steering knuckle, and make sure that it is tightened to the right torque, also use a new cotter pin so that it can align properly. Push the outer end of the driveaxle to the steering knuckle and screw in the nut tightly, but do not overtighten it at this stage. Fasten the balljoint to the lower arm and while fastening make sure that the fasteners attain the following torque. Replace wheel speed sensor and then the wheel then the lug nuts, drop the car and then again tighten the lug nuts to the recommended torque. Last of all, ensure that the driveaxle/hub nut is properly torqued to the correct specifications and then go ahead and staking the nut.

Related Toyota Highlander Parts

Browse by Year

2024 Ball Joint 2023 Ball Joint 2022 Ball Joint 2021 Ball Joint 2020 Ball Joint 2019 Ball Joint 2018 Ball Joint 2017 Ball Joint 2016 Ball Joint 2015 Ball Joint 2014 Ball Joint 2013 Ball Joint 2012 Ball Joint 2011 Ball Joint 2010 Ball Joint 2009 Ball Joint 2008 Ball Joint 2007 Ball Joint 2006 Ball Joint 2005 Ball Joint 2004 Ball Joint 2003 Ball Joint 2002 Ball Joint 2001 Ball Joint