My Garage

My Account

Cart

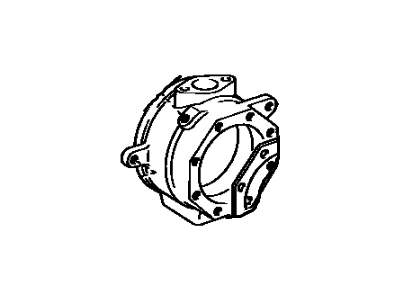

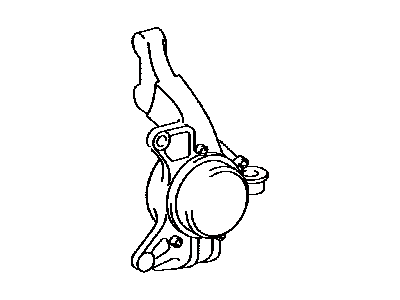

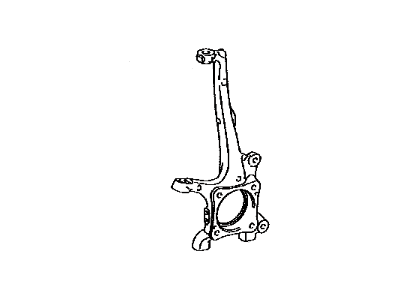

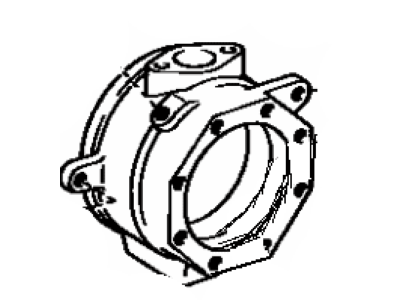

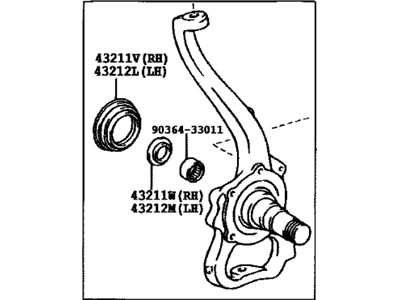

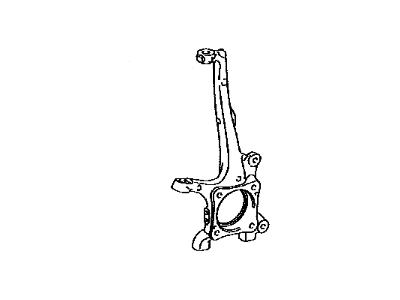

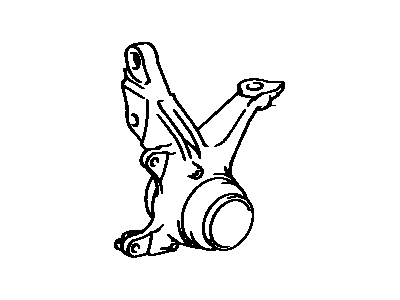

Genuine Toyota Land Cruiser Steering Knuckle

Front Steering Knuckle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Steering Knuckles found

Toyota Land Cruiser Steering Knuckle Right Hand

Part Number: 43211-60120$302.86 MSRP: $434.29You Save: $131.43 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Left Hand

Part Number: 43202-60020$734.11 MSRP: $1096.14You Save: $362.03 (34%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Left Hand

Part Number: 43212-60230$580.27 MSRP: $866.42You Save: $286.15 (34%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Left Hand

Part Number: 43212-60120$302.86 MSRP: $434.29You Save: $131.43 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Right Hand

Part Number: 43201-60020$774.00 MSRP: $1155.68You Save: $381.68 (34%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Right Hand

Part Number: 43211-60190$569.47 MSRP: $850.29You Save: $280.82 (34%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Left Hand

Part Number: 43212-60110$184.51 MSRP: $264.57You Save: $80.06 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Right Hand

Part Number: 43211-60110$184.43 MSRP: $264.45You Save: $80.02 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Right Hand

Part Number: 43211-60230$581.61 MSRP: $868.43You Save: $286.82 (34%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Left Hand

Part Number: 43212-60190$569.47 MSRP: $850.29You Save: $280.82 (34%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Left Hand

Part Number: 43212-60020$162.49 MSRP: $231.01You Save: $68.52 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Right Hand

Part Number: 43211-60020$134.33 MSRP: $190.97You Save: $56.64 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Steering Knuckle Left Hand

Part Number: 43212-60032$219.85 MSRP: $315.25You Save: $95.40 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 24 Results

Toyota Land Cruiser Steering Knuckle

If you are in demand for superior quality and affordable OEM Toyota Land Cruiser Steering Knuckle, then shop with us! We own a wide range of the reduced-priced genuine Toyota Land Cruiser Steering Knuckle. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Land Cruiser Steering Knuckle Parts Questions & Experts Answers

- Q: How to remove and install Steering Knuckle on Toyota Land Cruiser?A:To change a wheel, the lug nuts must be unscrewed, the vehicle has to be lifted and placed on jack stands before the wheel can be changed. Then, the tie-rod shall be detached from the steering knuckle together with removal of brake parts. Following that, remove the front axle axleshaft and unfasten the steering knuckle oil seal by using the oil seal retainer bolts. Turn to the upper Side to take of the steering knuckle arm retaining nuts ad cone washers, go down and take a hold of the lower steering arm assembly and pull down to detach it from the knuckle. Next, remove the upper bearing cap along with the shim, if installed, and then the steering knuckle, where one has to twist the upper bearing cap off. It is important not to mix the bearings hence label the bearings, and use solvent to wash out all the bearing grease from the bearings, axle tube yoke, and steering knuckle while ensuring that the bristles do not get lodged in between the roller bearings. The bearings should be in good condition and the bearing races attached to the inside of the axle tube yoke should also be checked for signs of wear; if they are worn one must drive out the worn race and install a new one with the bearing driver. Check and make sure the bearings are packed with high temperature wheel bearing grease and that there is grease film on each bearing race. Fit a new steering knuckle oil seal, then press the upper bearing into the axle tube yoke; position the lower bearing. Place the steering knuckle over the axle tube yoke and tighten the upper bearing cap, and spacer then put the upper bearing cap bolts. Refit the steering knuckle arm, cone washers and retainers and tighten the nuts by the required tightening torque. To check the bearing preload, use a spring tension gauge, tightening the nut further if the preload needs to be increased, and putting on the correct size shim if the preload needs to be reduced. Last of all, it is advisable to complete the installation by using the corresponding removal steps in the reverse order.

Related Toyota Land Cruiser Parts

Browse by Year

2021 Steering Knuckle 2020 Steering Knuckle 2019 Steering Knuckle 2018 Steering Knuckle 2017 Steering Knuckle 2016 Steering Knuckle 2015 Steering Knuckle 2014 Steering Knuckle 2013 Steering Knuckle 2012 Steering Knuckle 2011 Steering Knuckle 2010 Steering Knuckle 2009 Steering Knuckle 2008 Steering Knuckle 2007 Steering Knuckle 2006 Steering Knuckle 2005 Steering Knuckle 2004 Steering Knuckle 2003 Steering Knuckle 2002 Steering Knuckle 2001 Steering Knuckle 2000 Steering Knuckle 1999 Steering Knuckle 1998 Steering Knuckle 1997 Steering Knuckle 1996 Steering Knuckle 1995 Steering Knuckle 1994 Steering Knuckle 1993 Steering Knuckle 1992 Steering Knuckle 1991 Steering Knuckle 1990 Steering Knuckle 1989 Steering Knuckle 1988 Steering Knuckle 1987 Steering Knuckle 1986 Steering Knuckle 1985 Steering Knuckle 1984 Steering Knuckle 1983 Steering Knuckle 1982 Steering Knuckle 1981 Steering Knuckle 1980 Steering Knuckle 1979 Steering Knuckle 1978 Steering Knuckle 1977 Steering Knuckle 1976 Steering Knuckle 1975 Steering Knuckle 1974 Steering Knuckle 1973 Steering Knuckle 1972 Steering Knuckle 1971 Steering Knuckle 1970 Steering Knuckle 1969 Steering Knuckle