My Garage

My Account

Cart

Genuine Toyota Prius Battery Cable

Car Battery Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Battery Cables found

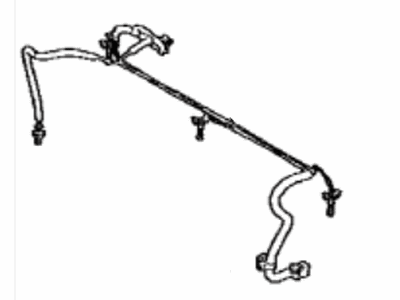

Toyota Prius Main Battery Cable

Part Number: G9242-47090$29.42 MSRP: $41.12You Save: $11.70 (29%)Ships in 1-3 Business DaysToyota Prius Main Battery Cable

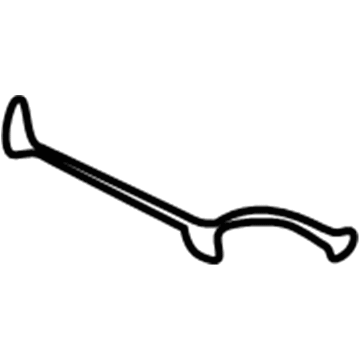

Part Number: G9242-47100$11.55 MSRP: $16.15You Save: $4.60 (29%)Ships in 1-3 Business DaysToyota Prius Wire, Hv Battery Pack

Part Number: G92X2-47010$19.62 MSRP: $27.42You Save: $7.80 (29%)Ships in 1-3 Business DaysToyota Prius HV Battery Thermistor

Part Number: G9282-47060$85.08 MSRP: $119.93You Save: $34.85 (30%)Ships in 1-3 Business DaysToyota Prius Bond Cable

Part Number: 90980-07450$22.28 MSRP: $31.15You Save: $8.87 (29%)Ships in 1-3 Business DaysToyota Prius THERMISTOR, Hv BATTE

Part Number: G9282-47050$83.49 MSRP: $117.69You Save: $34.20 (30%)Ships in 1-3 Business DaysToyota Prius Main Battery Cable

Part Number: G9242-47040$11.07 MSRP: $15.48You Save: $4.41 (29%)Ships in 1-3 Business DaysToyota Prius Bond Cable

Part Number: 90980-07392$12.97 MSRP: $18.13You Save: $5.16 (29%)Ships in 1-3 Business DaysToyota Prius Thermistor, Hybrid Battery

Part Number: G9282-47030$27.83 MSRP: $38.91You Save: $11.08 (29%)Ships in 1-3 Business DaysToyota Prius Bond Cable

Part Number: 90980-07310$9.81 MSRP: $13.71You Save: $3.90 (29%)Ships in 1-3 Business DaysToyota Prius Bond Cable

Part Number: 90980-07292$16.73 MSRP: $23.39You Save: $6.66 (29%)Ships in 1-3 Business DaysToyota Prius Bond Cable

Part Number: 90980-07463$18.91 MSRP: $26.43You Save: $7.52 (29%)Ships in 1-3 Business DaysToyota Prius Wire Earth NO.2

Part Number: 82286-12010$31.17 MSRP: $43.57You Save: $12.40 (29%)Ships in 1-3 Business Days

Toyota Prius Battery Cable

If you are in demand for superior quality and affordable OEM Toyota Prius Battery Cable, then shop with us! We own a wide range of the reduced-priced genuine Toyota Prius Battery Cable. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Prius Battery Cable Parts Questions & Experts Answers

- Q: How should you periodically inspect battery cables for damage and corrosion on Toyota Prius?A:Periodically inspect each battery cable for damage, cracked or burned insulation, and corrosion, as poor connections can lead to starting problems and decreased engine performance. Check the cable-to-terminal connections for cracks, loose wire strands, and corrosion; white, fluffy deposits under the insulation indicate corrosion and necessitate replacement. When removing cables, always disconnect the negative cable first and connect it last to avoid shorting the battery. Disconnect the old cables from the battery, trace them to their opposite ends, and detach them from the terminals, noting the routing for correct installation. If replacing cables, take the old ones to ensure identical parts; positive cables are typically red, larger in cross-section, and have a larger diameter battery post clamp, while ground cables are usually black, smaller, and have a slightly smaller diameter clamp. Clean the threads of the solenoid or ground connection with a wire brush to remove rust and corrosion, then apply a light coat of battery terminal corrosion inhibitor or petroleum jelly to prevent future corrosion. Attach the cable to the solenoid or ground connection and securely tighten the mounting nut or bolt. Before connecting a new cable to the battery, ensure it reaches the battery post without stretching, and connect the positive cable first, followed by the negative cable.

Related Toyota Prius Parts

Browse by Year

2024 Battery Cable 2023 Battery Cable 2022 Battery Cable 2021 Battery Cable 2020 Battery Cable 2019 Battery Cable 2018 Battery Cable 2017 Battery Cable 2016 Battery Cable 2015 Battery Cable 2014 Battery Cable 2013 Battery Cable 2012 Battery Cable 2011 Battery Cable 2010 Battery Cable 2009 Battery Cable 2008 Battery Cable 2007 Battery Cable 2006 Battery Cable 2005 Battery Cable 2004 Battery Cable 2003 Battery Cable 2002 Battery Cable 2001 Battery Cable