My Garage

My Account

Cart

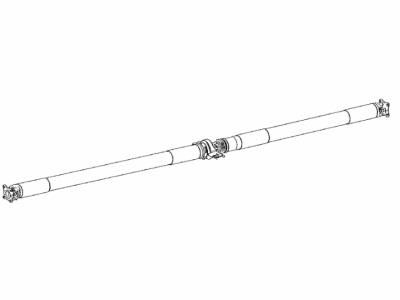

Genuine Toyota RAV4 Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Drive Shafts found

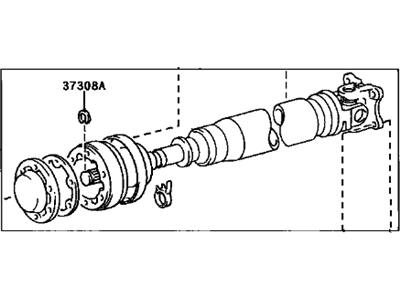

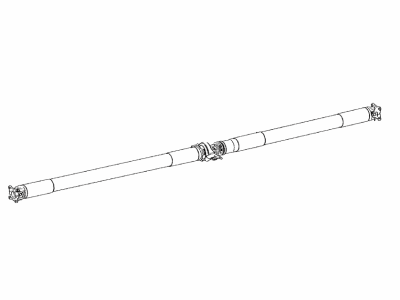

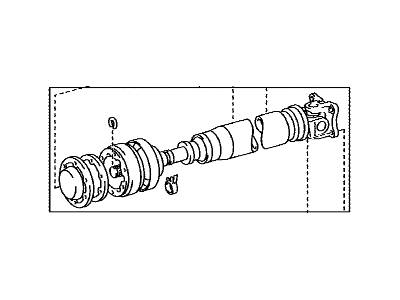

Toyota RAV4 Propeller Shaft Assembly with Center Bearing

Part Number: 37100-42090$695.68 MSRP: $1038.75You Save: $343.07 (34%)Ships in 1-3 Business DaysToyota RAV4 Propeller Shaft Assembly with Center Bearing

Part Number: 37100-42060$736.79 MSRP: $1100.13You Save: $363.34 (34%)Ships in 1-3 Business DaysToyota RAV4 Propeller Shaft Assembly with Center Bearing

Part Number: 37100-42021$526.41 MSRP: $785.30You Save: $258.89 (33%)Ships in 1-3 Business DaysToyota RAV4 Propelle Shaft Assembly

Part Number: 37100-42070$809.87 MSRP: $1209.24You Save: $399.37 (34%)Ships in 1-3 Business DaysToyota RAV4 Propelle Shaft Assembly

Part Number: 37110-42040$322.35 MSRP: $462.22You Save: $139.87 (31%)Ships in 1-3 Business DaysToyota RAV4 Propelle Shaft Assembly

Part Number: 37100-42100$654.35 MSRP: $977.04You Save: $322.69 (34%)Ships in 1-3 Business DaysToyota RAV4 Propeller Shaft Assembly with Center Bearing

Part Number: 37100-42040$871.14 MSRP: $1300.74You Save: $429.60 (34%)Ships in 1-3 Business DaysToyota RAV4 Propeller Intermediate Shaft Assembly

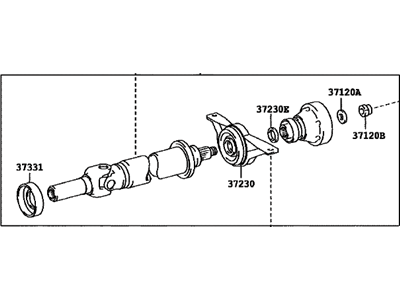

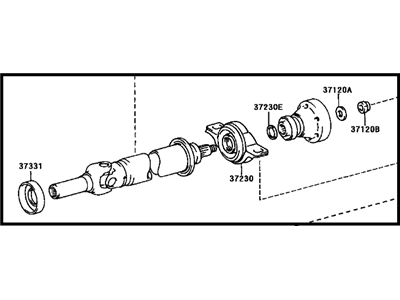

Part Number: 37120-42010$388.25 MSRP: $579.20You Save: $190.95 (33%)Ships in 1-3 Business DaysToyota RAV4 Propeller Intermediate Shaft Assembly

Part Number: 37120-42030$332.99 MSRP: $477.48You Save: $144.49 (31%)Ships in 1-3 Business DaysToyota RAV4 Propeller Intermediate Shaft Assembly

Part Number: 37120-42020$396.22 MSRP: $591.07You Save: $194.85 (33%)Ships in 1-3 Business DaysToyota RAV4 Propeller Shaft Assembly with Center Bearing

Part Number: 37100-42010$526.41 MSRP: $785.30You Save: $258.89 (33%)Ships in 1-3 Business DaysToyota RAV4 Propeller Shaft Assembly with Center Bearing

Part Number: 37100-0R010$695.68 MSRP: $1038.75You Save: $343.07 (34%)Ships in 1-3 Business Days

Toyota RAV4 Drive Shaft

If you are in demand for superior quality and affordable OEM Toyota RAV4 Drive Shaft, then shop with us! We own a wide range of the reduced-priced genuine Toyota RAV4 Drive Shaft. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota RAV4 Drive Shaft Parts Questions & Experts Answers

- Q: How to check and remove the Drive Shaft on a Toyota Rav4?A:Firstly, lift the rear of the vehicle and use jackstands to support them and turn the front wheels and set the parking brake, likewise, engage the transmission on the Neutral. Next, move around the car and crawl under it to check the outer surface of the car driveshaft; Whereby, if there are any form of dent or crack, then the Shafts needs to be replaced. From the transfer case connection one has to check for leakage at this end because this is commonly caused by a bad seal while at the Differential end if one observes leakage then there is a common problem with the pinion seal. As an assistant turns a rear wheel, look for the universal joints without wobbling, squeaking, or looseness, carefully listening for any coming from the middle bearing; The rubber part should be checked for cracks or their separation. The universal joints can be checked without the driveshaft being in motion, by attempting to twist the joint; any sideways movement is indicative of severe wear and there will usually be movement if the shaft is lifted; in such a situation the driveshaft assembly will require replacement. Last but not the least, make sure that the drive shaft mounting bolts are well tightened. To remove and install the differential, again jack up the rear of the vehicle and support with jack stands, and chock the front wheels. While in this position and with the transmission in Neutral and with the parking brake off, one can make reference marks on the flanges of the both driveshaft and the differential pinion for realignment whenever the two are to be re-positioned. Loosen and take out the bolts holding the centre support bearing and slowly drop it, remove the rear universal joint flange nuts and the washers and rotate the driveshaft in order to gain access. Then it is necessary to unscrew and take off the nuts and washers of the transfer unit output shaft flange in the same way as before and finally the driveshaft. Reinstallation is an inverted process of the removal where the driveshaft is connected to the flange of the transfer unit next to the differential flange; it is positioned well to fit the marks and the fasteners are tightened. Last but not the least, place the center support bearing bracket on the floorpan and then fasten the bolts.

Browse by Year

2024 Drive Shaft 2023 Drive Shaft 2022 Drive Shaft 2021 Drive Shaft 2020 Drive Shaft 2019 Drive Shaft 2018 Drive Shaft 2017 Drive Shaft 2016 Drive Shaft 2015 Drive Shaft 2014 Drive Shaft 2013 Drive Shaft 2012 Drive Shaft 2011 Drive Shaft 2010 Drive Shaft 2009 Drive Shaft 2008 Drive Shaft 2007 Drive Shaft 2006 Drive Shaft 2005 Drive Shaft 2004 Drive Shaft 2003 Drive Shaft 2002 Drive Shaft 2001 Drive Shaft 2000 Drive Shaft 1999 Drive Shaft 1998 Drive Shaft 1997 Drive Shaft 1996 Drive Shaft