My Garage

My Account

Cart

Genuine Toyota RAV4 Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

59 Pistons found

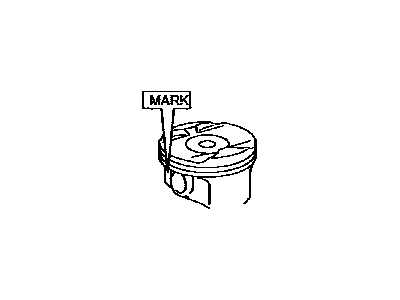

Toyota RAV4 Piston

Part Number: 13211-0V012-B0$92.03 MSRP: $129.73You Save: $37.70 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-31090$60.14 MSRP: $84.79You Save: $24.65 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-31092-A0$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-28031-A0$99.70 MSRP: $140.54You Save: $40.84 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-31092-B0$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-0V012-A0$92.03 MSRP: $129.73You Save: $37.70 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-36032-A0$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-25030$86.36 MSRP: $121.74You Save: $35.38 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-36032-B0$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-28110-A0$99.34 MSRP: $140.04You Save: $40.70 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-28110-B0$101.35 MSRP: $142.87You Save: $41.52 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-36090-A0$86.45 MSRP: $121.85You Save: $35.40 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-31091$60.14 MSRP: $84.79You Save: $24.65 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-25040$85.89 MSRP: $121.08You Save: $35.19 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-31092-C0$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-36030-A0$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-36032-C0$95.10 MSRP: $134.05You Save: $38.95 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-28111-A0$99.34 MSRP: $140.04You Save: $40.70 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston

Part Number: 13211-36031-B0$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Piston Sub-Assembly with Pin

Part Number: 13101-74191-02$106.71 MSRP: $150.41You Save: $43.70 (30%)

| Page 1 of 3 |Next >

1-20 of 59 Results

Toyota RAV4 Piston

If you are in demand for superior quality and affordable OEM Toyota RAV4 Piston, then shop with us! We own a wide range of the reduced-priced genuine Toyota RAV4 Piston. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota RAV4 Piston Parts Questions & Experts Answers

- Q: How to remove piston/connecting rod assemblies on Toyota Rav4?A:Before disassembling the piston and connecting rod assemblies, the cylinder head, oil pan, balancer assembly, and the lower crankcase have to be almost dismantled. To start with, inspect for any ridge at the limit of ring travel in each cylinder and onwards, if present, should be scraped off with a special tool. Next unscrew the four spikes / ridges that are used to align the connecting rods and with the crankshaft standing upright check the end-float using the feeler gauges, the amount should be within the service limit. Locate rodents with marks, then remove the connecting rod cap and bearing insert, and pushing the connecting rod/ piston assembly up and out through the top of the engine. This procedure has to be done for the rest of cylinders and then the caps and inserts must be tightly screwed back on to preserve the bearing metal. The pistons and connecting rods are swung around which are then in a position to be inspected and refurbished. When carburetor is rebuilt or newly pistons rings are to be fitted make sure that the rings sides and end gaps are correct and also the side clearance of piston rings. Place the first piston to the first set of ring and cylinder and then holding the top ring, place it to the cylinder and checked the measuring of end gap of the ring with the feeler gauge. If the gap needs to be increased or decreased, the gap should be filed by progreesively narrowing the ring ends. The correct position of the rings depends on their specific designation; begin with the oil control ring, then the middle and the top. Before the piston/connecting rod assemblies installation, it is required to deglaze the cylinder walls and to provide the rounding of the top edge of the cylinder bores. Examining the connecting rod, require that the bearing surfaces are clean, and the new bearing inserts will fit impeccably. Align the gaps of the pistin rings to be at right angles between each other, grease the piston and the rings, and finally use a piston ring compressor for this. Slide the piston/connecting rod assembly into the cylinder bore such that the connecting rod eye is pointed at the crankshaft journal. Ensure that the connecting rod bearing oil clearance is correct with Plastigage and if not correct the bearing inserts. To restore the used Plastigage material, clean the bearing faces using a solvent and then coat with a layer of grease, re-install the connecting rod and finally torque up the rod cap bolts as recommended. Perform the same for the other assemblies, make sure they are clean, and oriented in the right direction. Last, take the crankshaft and turn it in order to feel whether there is any binding and then again check the end play of the connecting rod and adjust as per the requirements.

Related Toyota RAV4 Parts

Browse by Year

2024 Piston 2023 Piston 2022 Piston 2021 Piston 2020 Piston 2019 Piston 2018 Piston 2017 Piston 2016 Piston 2015 Piston 2014 Piston 2013 Piston 2012 Piston 2011 Piston 2010 Piston 2009 Piston 2008 Piston 2007 Piston 2006 Piston 2005 Piston 2004 Piston 2003 Piston 2002 Piston 2001 Piston 2000 Piston 1999 Piston 1998 Piston 1997 Piston 1996 Piston