My Garage

My Account

Cart

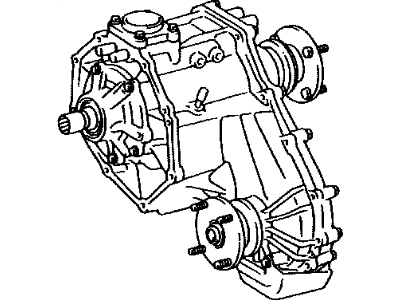

Genuine Toyota Sequoia Transfer Case

Speed Transfer Case- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Transfer Cases found

Toyota Sequoia Case, Transfer, Rear

Part Number: 36112-35090$400.61 MSRP: $597.63You Save: $197.02 (33%)Ships in 1-3 Business DaysToyota Sequoia Transfer Assembly

Part Number: 36100-34193$2446.11 MSRP: $3106.17You Save: $660.06 (22%)Ships in 1-3 Business DaysToyota Sequoia Transfer Assembly

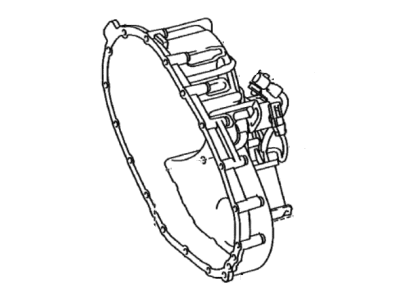

Part Number: 36100-34191$2024.37 MSRP: $2570.63You Save: $546.26 (22%)Toyota Sequoia Case Transfer Front

Part Number: 36111-35070$978.56 MSRP: $1461.12You Save: $482.56 (34%)Ships in 1-3 Business DaysToyota Sequoia Case Sub Assembly Trans

Part Number: 36103-0C020$1112.93 MSRP: $1661.76You Save: $548.83 (34%)Ships in 1-3 Business DaysToyota Sequoia Transfer Assembly

Part Number: 36110-34040$3283.72 MSRP: $4169.79You Save: $886.07 (22%)Ships in 1-3 Business DaysToyota Sequoia Transaxle Case Sub-Assembly

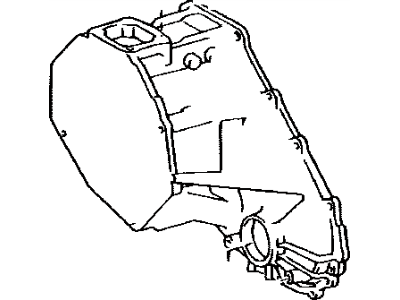

Part Number: 36104-34044$409.32 MSRP: $610.62You Save: $201.30 (33%)Ships in 1-3 Business DaysToyota Sequoia Transaxle Case Sub-Assembly

Part Number: 36104-34043$423.93 MSRP: $632.43You Save: $208.50 (33%)Ships in 1-3 Business DaysToyota Sequoia Transaxle Case Sub-Assembly

Part Number: 36104-34041$535.03 MSRP: $798.15You Save: $263.12 (33%)Ships in 1-3 Business DaysToyota Sequoia Transaxle Case Sub-Assembly

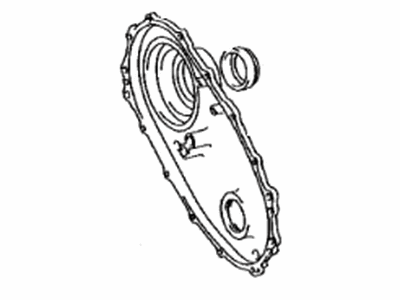

Part Number: 36103-34031$633.88 MSRP: $946.47You Save: $312.59 (34%)Ships in 1-3 Business DaysToyota Sequoia Transfer Case Sub-Assembly Front

Part Number: 36103-34030$1267.74 MSRP: $1892.91You Save: $625.17 (34%)Ships in 1-3 Business DaysToyota Sequoia Transmission Case Sub Assembly

Part Number: 36104-0C020$80.15 MSRP: $112.98You Save: $32.83 (30%)Ships in 1-3 Business DaysToyota Sequoia Transfer Assembly

Part Number: 36100-34192$2446.11 MSRP: $3106.17You Save: $660.06 (22%)Ships in 1-3 Business DaysToyota Sequoia Transfer Assembly

Part Number: 36100-34183$3008.57 MSRP: $3820.39You Save: $811.82 (22%)Ships in 1-3 Business DaysToyota Sequoia Transfer Assembly

Part Number: 36100-34181$2952.72 MSRP: $3749.48You Save: $796.76 (22%)Ships in 1-3 Business DaysToyota Sequoia Transfer Assembly

Part Number: 36100-34182$3041.88 MSRP: $3862.69You Save: $820.81 (22%)Ships in 1-3 Business Days

Toyota Sequoia Transfer Case

If you are in demand for superior quality and affordable OEM Toyota Sequoia Transfer Case, then shop with us! We own a wide range of the reduced-priced genuine Toyota Sequoia Transfer Case. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Sequoia Transfer Case Parts Questions & Experts Answers

- Q: Is overhauling a transfer case a difficult job for the do-it-yourselfer on Toyota Sequoia?A:In a manner adroit, rebuilding a transfer is not easy for the do-it-yourselfer because of many intricate parts which are in sequences sold in sets, having to measure tiny clearance and possible reconditioning with spacers and snap rings. Although the average, capable person can replace the transfer case or even do the swapping, the overhaul is a job that is advisable to be done by a transmission repair shop since the time needed and the cost exceeds a rebuilt transfer case that may be available from the dealer parts department or auto part stores. Thus, although it is possible for an inexperienced mechanic to successfully rebuild a transfer case, special tools and a methodical approach to the task will be necessary to ensure that nothing is missed. Some of the necessary equipment for the job are snap ring internal/external pliers, puller for bearings, slide hammer, combination set of pin punches, dial indicator, probably hydraulic press and robust table and vise or transfer case stand. Pertaining to disassembly steps, it is very vital to note down every position and how the components were mounted. Moreover, knowing the troubled area in the transfer case makes the investigation and, if necessary, the replacement or removal of certain elements more manageable.

Related Toyota Sequoia Parts

Browse by Year

2025 Transfer Case 2024 Transfer Case 2023 Transfer Case 2022 Transfer Case 2021 Transfer Case 2020 Transfer Case 2019 Transfer Case 2018 Transfer Case 2017 Transfer Case 2016 Transfer Case 2015 Transfer Case 2014 Transfer Case 2013 Transfer Case 2012 Transfer Case 2011 Transfer Case 2010 Transfer Case 2009 Transfer Case 2008 Transfer Case 2007 Transfer Case 2006 Transfer Case 2005 Transfer Case 2004 Transfer Case 2003 Transfer Case 2002 Transfer Case 2001 Transfer Case