My Garage

My Account

Cart

Genuine Toyota Sienna ABS Control Module

Anti Lock Brake Control Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

45 ABS Control Modules found

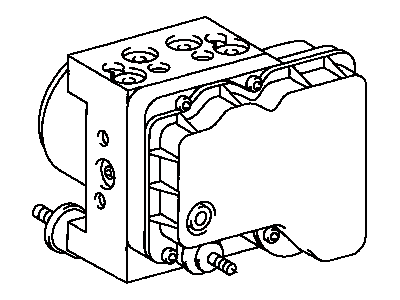

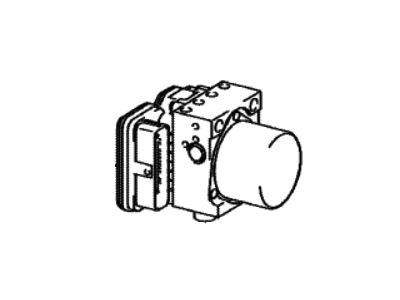

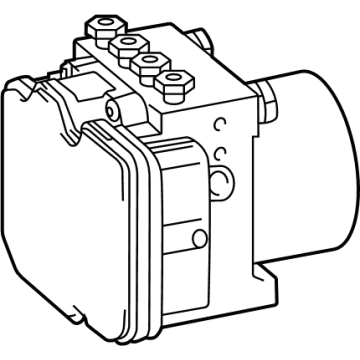

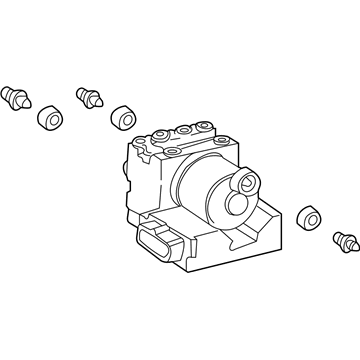

Toyota Sienna Brake Actuator Assembly

Part Number: 44050-08061$1038.79 MSRP: $1332.29You Save: $293.50 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08150$1068.31 MSRP: $1370.15You Save: $301.84 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

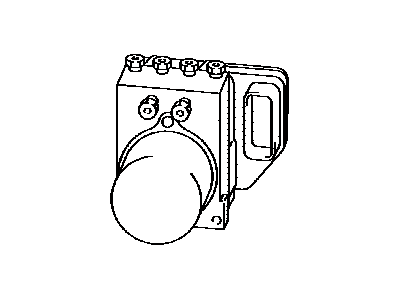

Part Number: 44050-08221$963.71 MSRP: $1236.00You Save: $272.29 (23%)Ships in 1-2 Business DaysToyota Sienna Skid Control Computer

Part Number: 89541-08020$2594.17 MSRP: $3873.46You Save: $1279.29 (34%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08200$1047.71 MSRP: $1343.72You Save: $296.01 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08160$951.34 MSRP: $1220.13You Save: $268.79 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08170$1037.90 MSRP: $1331.14You Save: $293.24 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08330$918.26 MSRP: $1177.70You Save: $259.44 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08350$821.17 MSRP: $1053.18You Save: $232.01 (23%)Ships in 1-2 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08290$954.69 MSRP: $1224.42You Save: $269.73 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08352$839.72 MSRP: $1076.97You Save: $237.25 (23%)Ships in 1-2 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08151$1061.85 MSRP: $1361.86You Save: $300.01 (23%)Toyota Sienna Brake Actuator Assembly

Part Number: 44050-45010$918.26 MSRP: $1177.70You Save: $259.44 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08260$947.78 MSRP: $1215.57You Save: $267.79 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08190$1010.83 MSRP: $1296.43You Save: $285.60 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08092$1579.54 MSRP: $2025.82You Save: $446.28 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08250$933.08 MSRP: $1196.70You Save: $263.62 (23%)Ships in 1-3 Business DaysToyota Sienna Brake Actuator Assembly

Part Number: 44050-08270$882.50 MSRP: $1131.84You Save: $249.34 (23%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 45 Results

Toyota Sienna ABS Control Module

If you are in demand for superior quality and affordable OEM Toyota Sienna ABS Control Module, then shop with us! We own a wide range of the reduced-priced genuine Toyota Sienna ABS Control Module. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Sienna ABS Control Module Parts Questions & Experts Answers

- Q: What is the purpose and function of the Anti-lock Brake System (ABS),ABS Control Module and Speed Sensor on Toyota Sienna?A:The Anti-lock Brake System (ABS) is designed to maintain vehicle steerability, directional stability, and optimum deceleration under severe braking conditions and on most road surfaces by monitoring the rotational speed of each wheel and controlling brake line pressure to prevent wheel lock-up. It works in conjunction with Automatic Skid Control and tire pressure warning systems, where the former helps control skids by braking outside wheels during oversteering, and the latter alerts the driver to low tire pressure through a dashboard light. The actuator assembly includes the master cylinder, an electric hydraulic pump, and four solenoid valves that modulate brake line pressure during ABS operation. Speed sensors located at each wheel generate electrical pulsations to indicate wheel rotational speed, with front sensors mounted to the steering knuckle and rear sensors bolted to the axle carriers. The ABS computer, housed within the actuator, processes information from the wheel speed sensors to control hydraulic line pressure and monitors the system for faults, illuminating an "ABS" light on the dashboard if a problem arises. The built-in self-diagnosis system detects sensor malfunctions and stores failure codes, which can be accessed by turning the ignition key off and using jumper wires on the data link connectors. The ABS warning light indicates diagnostic codes through a series of flashes, with specific patterns corresponding to different malfunctions. After diagnosis, trouble codes can be cleared by jumping terminals on the data link connector and pressing the brake pedal multiple times, after which the system or component should be checked or serviced as needed.

Related Toyota Sienna Parts

Browse by Year

2024 ABS Control Module 2023 ABS Control Module 2022 ABS Control Module 2021 ABS Control Module 2020 ABS Control Module 2019 ABS Control Module 2018 ABS Control Module 2017 ABS Control Module 2016 ABS Control Module 2015 ABS Control Module 2014 ABS Control Module 2013 ABS Control Module 2012 ABS Control Module 2011 ABS Control Module 2010 ABS Control Module 2009 ABS Control Module 2008 ABS Control Module 2007 ABS Control Module 2006 ABS Control Module 2005 ABS Control Module 2004 ABS Control Module 2003 ABS Control Module 2002 ABS Control Module 2001 ABS Control Module 2000 ABS Control Module 1999 ABS Control Module 1998 ABS Control Module