My Garage

My Account

Cart

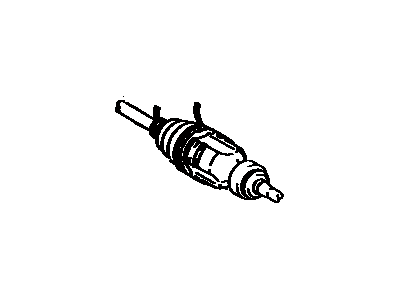

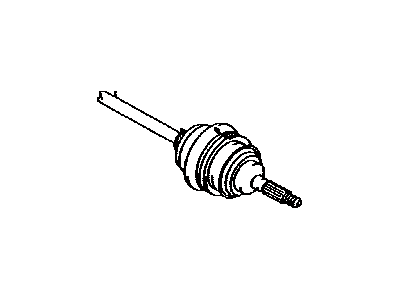

Genuine Toyota Solara Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

55 Axle Shafts found

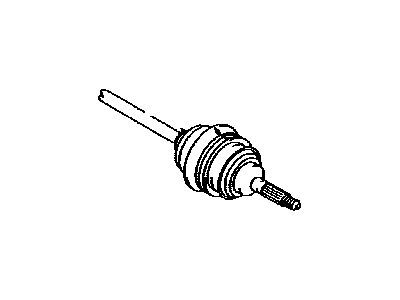

Toyota Solara Front Drive Shaft Assembly Left Hand

Part Number: 43420-08010$397.37 MSRP: $592.80You Save: $195.43 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Left Hand

Part Number: 43420-06450$451.34 MSRP: $673.30You Save: $221.96 (33%)Toyota Solara Shaft Assembly, Front Cv Axle, Left

Part Number: 43420-06490$456.80 MSRP: $681.46You Save: $224.66 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Left Hand

Part Number: 43420-06161$222.85 MSRP: $422.71You Save: $199.86 (48%)Ships in 1-2 Business DaysToyota Solara Front Drive Outboard Joint Shaft Assembly Left Hand

Part Number: 43470-09A16$199.39 MSRP: $285.91You Save: $86.52 (31%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06330$457.62 MSRP: $682.68You Save: $225.06 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06271$522.03 MSRP: $778.76You Save: $256.73 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Outboard Joint Shaft Assembly Left Hand

Part Number: 43470-09890$236.83 MSRP: $339.59You Save: $102.76 (31%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Left Hand

Part Number: 43420-06251$340.11 MSRP: $487.70You Save: $147.59 (31%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06281$384.34 MSRP: $573.35You Save: $189.01 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Left Hand

Part Number: 43420-06460$390.00 MSRP: $581.80You Save: $191.80 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Left Hand

Part Number: 43420-06261$422.13 MSRP: $629.73You Save: $207.60 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Left Hand

Part Number: 43420-06262$422.13 MSRP: $629.73You Save: $207.60 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06261$423.69 MSRP: $632.05You Save: $208.36 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06460$500.94 MSRP: $747.30You Save: $246.36 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06251$501.11 MSRP: $747.56You Save: $246.45 (33%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06252$501.11 MSRP: $747.56You Save: $246.45 (33%)Ships in 1-3 Business DaysToyota Solara Shaft Assembly Front Drive Outboard Joint Right

Part Number: 43460-09630$524.89 MSRP: $783.02You Save: $258.13 (33%)Ships in 1-3 Business DaysToyota Solara Shaft Assembly Front Drive Outboard Joint Right

Part Number: 43460-09640$614.57 MSRP: $917.64You Save: $303.07 (34%)Ships in 1-3 Business DaysToyota Solara Front Drive Shaft Assembly Right Hand

Part Number: 43410-06221$501.40 MSRP: $748.00You Save: $246.60 (33%)

| Page 1 of 3 |Next >

1-20 of 55 Results

Toyota Solara Axle Shaft

The Axle Shaft of Toyota Solara vehicles is an important component, which transmit torque from the differential system to the drive wheels to provide independent rotation, consequently increasing the tractive force. All these steel shafts are of different types including the solid axles for trucks and older cars and half shafts for the cars with independent suspension system. Differentials as well as axle shafts are established by solid axles, and half axles transmit force from the transaxle to the wheels. Each type can become worn with time and as such can cause noises, vibrations and possibly loss of lubricant. Axle shafts are crucial components to support the weight of the vehicle and transmit torque besides providing wheel alignment; thus, they are crucial for Toyota Solara automobiles.

If you are in demand for superior quality and affordable OEM Toyota Solara Axle Shaft, then shop with us! We own a wide range of the reduced-priced genuine Toyota Solara Axle Shaft. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

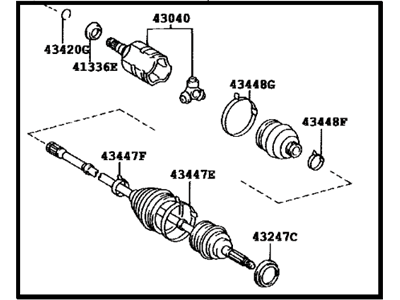

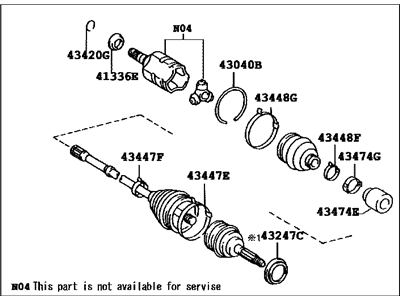

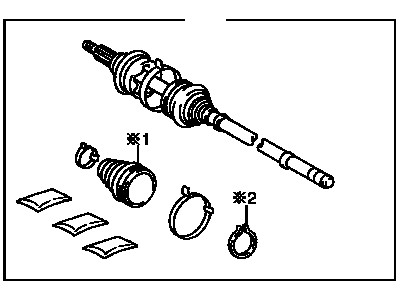

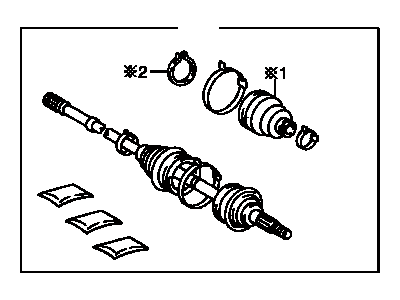

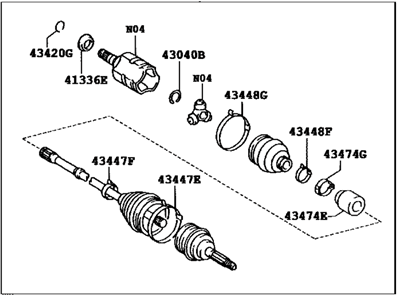

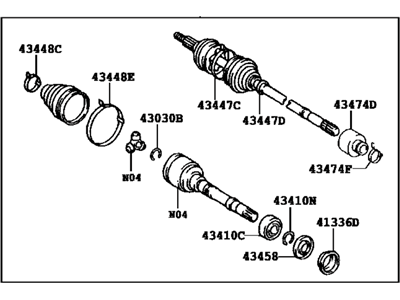

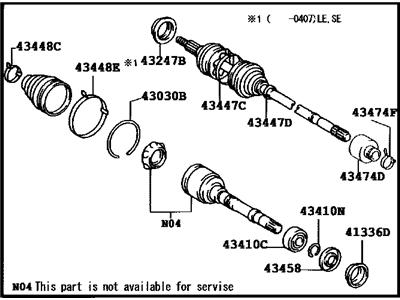

Toyota Solara Axle Shaft Parts Questions & Experts Answers

- Q: What Are the Components and Maintenance Practices for Axle Shafts and Constant Velocity Joints on 2002 through 2008 Toyota Solara?A:The torque is then transmitted into wheels through two axle shafts, with the inner ends being counsel to the transaxle and extended side gears of the differential and the outer ends being splined to the axle hubs, although a large nut is used to lock them. The left side axle shaft is shorter while that of the right side is longer and is provided with an intermediate shaft on the bearing. On the inner ends of the axle shafts, there are sliding CV joints allowing for angular and axial movements; there can be a tripod bearing with the joint tulip or a ball and cage type of joint that slides as the axle shaft moves with the wheel. The mating parts of these joints are separable for cleaning if, for example, a whole boot has failed, while the damaged part must be replaced as a single entity. The ball bearings between the inner and outer races are of such nature that the angular movement only is possible at the outer joints. It is also important to inspect the boots for tears and leaks often since if the boots are worn out, or there is leakage of the lubricant, ripped boots may severely harm the animals' joints. Ordinarily, boot replacement entails axle shaft extraction, although there is the so-called split type of boots that can be fitted fairly easily. But, dismantling the axle shaft and washing the CV joint is advised to get rid of particles which worsens the wear. Signs of worn or damaged CV joints include the leakage of lubricants, noises especially when the car is turning, clamping sound when accelerating after coasting, and vibrations at high speeds excluding when accelerating. To check for wear, take each axle at a time and while holding the joint of the CV by hands, rotate the axle and feel for such play on the splines or joint as if loose or worn, visually inspect the axle shaft for cracks, dents or any deformities.