My Garage

My Account

Cart

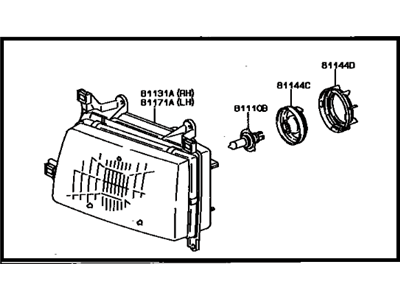

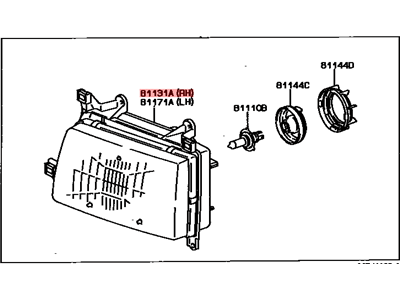

Genuine Toyota T100 Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Headlights found

Toyota T100 Headlight

The Toyota T100 Headlight is one of the parts of the vehicles, and it demonstrates that the brand is all about dependability and speed for the customers by providing safety and efficiency. The Toyota T100 Headlight is specifically intended for different models manufactured between 1993 and 1998, so that the drivers can have proper lighting at night and be more conspicuous to other motorists. The T100 employs today's highly popular composite headlamps containing halogen, LED and Xenon types of lighting, each with different merits in the aspects of illumination, operational life and energy consumption. Halogen Headlight, which have been dominant in earlier models, demonstrate the assembly of the ability to offer inexpensive options, whereas LEDs or xenon Headlight are distinguished by their constitution and better lighting, lifespan over 50 thousand hours. This change in the Toyota T100 Headlight mould portrays a great improvement in automotive safety and looks. Given that the T100 is positioned between mid-sized competitors and full-size trucks, this specifically underlines the role of the Headlight system in improving the vehicle's performance. Accredited by its quality, the Toyota T100 was awarded for instance, the J.D. Power and associates initial quality survey highly full-size pickup and this included warranty of the components of the car such as the Headlight system. Finally, the Toyota T100 Headlight improves the vehicle's performance while strengthening Toyota's tagline of manufacturing reliable automobiles that guarantee the safety of its users, in this case, the driver.

If you are in demand for superior quality and affordable OEM Toyota T100 Headlight, then shop with us! We own a wide range of the reduced-priced genuine Toyota T100 Headlight. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota T100 Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to ensure driver safety on Toyota T100?A:Thus, the headlights must be properly aligned so that the driver does not dazzle other drivers on the road and for achieving the best vision on the road. It is recommended that the aim should be checked at least once every one year or time the headlight is changed or front-end body work is done. The adjustment process involves two screws on the headlight housing: half would be designed for the vertical motion and the other half for the transverse motion. One of the elementary methods in adjustment needs a blank wall to the vehicle's front at a distance of 25 feet and, a level ground. The vertical masking tape must be used on the wall and such points as the centerline of the vehicle and the centerline of both headlights must be marked with the help of tapes; one horizontal tape line is also necessary. It is advised that the adjustments should be made when the vehicle is stationary, and the gas tank is half full, equally it should not be overloaded. Concerning low beams, the high-intensity zone should be located two inches below the horizontal line and two inches to the right of the vertical one. The vertical screw at the head of the apparatus varies the height of the beam and horizontal one-the direction of it. While the beam is on high, the high-intensity area is supposed to be below the straight line. Due to the Requirements or laws it may not be suitable to align both top and bottom beams to an optimum level, so for safety should adjust the bottom beams. One should need to get the car's headlights realigned by a professional as soon as possible.