My Garage

My Account

Cart

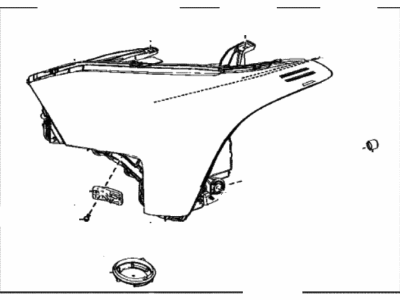

Genuine Toyota Tundra Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

66 Headlights found

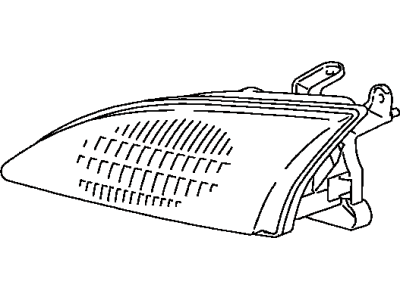

Toyota Tundra Driver Side Headlight Unit Assembly

Part Number: 81170-0C051$180.83 MSRP: $259.30You Save: $78.47 (31%)Ships in 1-3 Business DaysToyota Tundra Passenger Side Headlight Unit Assembly

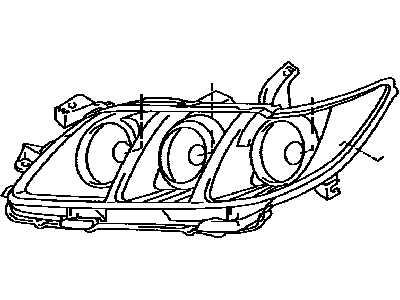

Part Number: 81130-0C051$180.83 MSRP: $259.30You Save: $78.47 (31%)Ships in 1-3 Business DaysToyota Tundra Driver Side Headlight Assembly

Part Number: 81150-0C091$268.99 MSRP: $385.71You Save: $116.72 (31%)Ships in 1-2 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C051$236.51 MSRP: $339.14You Save: $102.63 (31%)Ships in 1-3 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C091$271.08 MSRP: $388.71You Save: $117.63 (31%)Ships in 1-3 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C020$187.56 MSRP: $268.95You Save: $81.39 (31%)Ships in 1-2 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C010$187.56 MSRP: $268.95You Save: $81.39 (31%)Ships in 1-3 Business DaysToyota Tundra Passenger Side Headlight Assembly

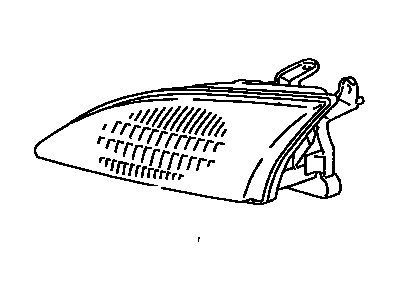

Part Number: 81110-0C210$339.98 MSRP: $487.52You Save: $147.54 (31%)Ships in 1-2 Business DaysToyota Tundra Driver Side Headlight Assembly Composite

Part Number: 81150-0C051$236.51 MSRP: $339.14You Save: $102.63 (31%)Ships in 1-2 Business DaysToyota Tundra Driver Side Headlight Assembly

Part Number: 81150-0C211$312.03 MSRP: $447.43You Save: $135.40 (31%)Ships in 1-3 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C070$326.41 MSRP: $468.06You Save: $141.65 (31%)Ships in 1-2 Business DaysToyota Tundra Driver Side Headlight Assembly

Part Number: 81150-0C010$187.56 MSRP: $268.95You Save: $81.39 (31%)Ships in 1-2 Business DaysToyota Tundra Driver Side Headlight Assembly

Part Number: 81150-0C020$187.56 MSRP: $268.95You Save: $81.39 (31%)Ships in 1-2 Business DaysToyota Tundra Driver Side Headlight Assembly

Part Number: 81150-0C070$321.42 MSRP: $460.90You Save: $139.48 (31%)Ships in 1-2 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C211$344.51 MSRP: $494.00You Save: $149.49 (31%)Ships in 1-3 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C130$236.40 MSRP: $338.98You Save: $102.58 (31%)Ships in 1-2 Business DaysToyota Tundra Driver Side Headlight Assembly

Part Number: 81150-0C111$232.34 MSRP: $333.15You Save: $100.81 (31%)Ships in 1-3 Business DaysToyota Tundra Passenger Side Headlight Assembly

Part Number: 81110-0C030$244.63 MSRP: $350.78You Save: $106.15 (31%)Ships in 1-3 Business DaysToyota Tundra Driver Side Headlight Assembly

Part Number: 81150-0C210$326.06 MSRP: $467.56You Save: $141.50 (31%)Ships in 1-2 Business DaysToyota Tundra Headlamp Assembly Right Hand

Part Number: 81110-0C260$1586.77 MSRP: $2369.26You Save: $782.49 (34%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 66 Results

Toyota Tundra Headlight

If you are in demand for superior quality and affordable OEM Toyota Tundra Headlight, then shop with us! We own a wide range of the reduced-priced genuine Toyota Tundra Headlight. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Tundra Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to ensure driver safety on Toyota Tundra?A:This creates a danger since the vehicle head lights must be aligned appropriately in a way that they do not blind the driver of another car or hinder visibility throughout the night and in poorly lit areas. The aim should be checked every 12 months and whenever there is a change of a front-headlight or if there is a replacement of front-end body work. The following is a procedure to lead to an effective temporary fix until the proper alignment can be done by a professional. Start with the Phillips head little screwdriver in order to manipulate the vertical mobility by the screws that can be found in the top part of the projector headlight. As a basic modification, stand a wall without any markings at a distance of twenty-five feet from the vehicle and preferably on a flat area. masking tape to mark out the vehicle centerline as well as the centerline of one head-light; place an additional horizontal tape line. It is preferable that the vehicle is not tilting; a gas tank halfway filled and no excess weight. Low beam adjustment can be done by aligning the high intensity zones two inches below the horizontal centrally drawn line on the front of the car and two inches to the side of the headlight's vertical line pointing towards oncoming traffic adjust the top screw clockwise to raise the beam and counterclockwise to lower it. It is noted that the high intensity part of the beam should be aimed at the point immediately below the horizontal axis, while low beams are used more often than high and are vital for safety. There may be slight misalignments that may need the attention of a dealer or an automotive service station in the shortest possible time.

Related Toyota Tundra Parts

Browse by Year

2024 Headlight 2023 Headlight 2022 Headlight 2021 Headlight 2020 Headlight 2019 Headlight 2018 Headlight 2017 Headlight 2016 Headlight 2015 Headlight 2014 Headlight 2013 Headlight 2012 Headlight 2011 Headlight 2010 Headlight 2009 Headlight 2008 Headlight 2007 Headlight 2006 Headlight 2005 Headlight 2004 Headlight 2003 Headlight 2002 Headlight 2001 Headlight 2000 Headlight