My Garage

My Account

Cart

Genuine Toyota Yaris Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Drive Belts found

Toyota Yaris V Belt

Part Number: 90916-02500$17.12 MSRP: $23.93You Save: $6.81 (29%)Ships in 1-3 Business DaysToyota Yaris V-Ribbed Belt

Part Number: 90916-02705$21.65 MSRP: $30.25You Save: $8.60 (29%)Ships in 1-3 Business DaysToyota Yaris V Belt

Part Number: 90916-02556$21.65 MSRP: $30.25You Save: $8.60 (29%)Ships in 1-2 Business DaysToyota Yaris Water Pump Belt

Part Number: 90118-WB464$20.17 MSRP: $28.19You Save: $8.02 (29%)Ships in 1 Business DayToyota Yaris V-Ribbed Belt

Part Number: 90916-02704$18.43 MSRP: $25.77You Save: $7.34 (29%)Ships in 1-3 Business DaysToyota Yaris V Belt

Part Number: 90916-02499$18.43 MSRP: $25.77You Save: $7.34 (29%)Ships in 1-2 Business Days

Toyota Yaris Drive Belt

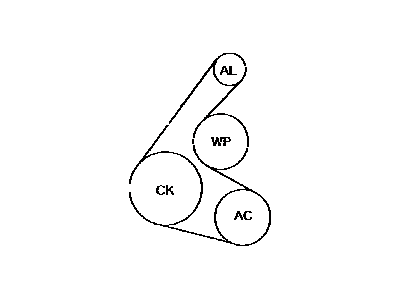

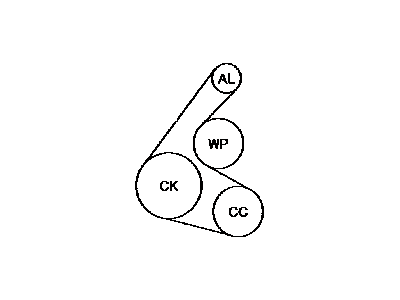

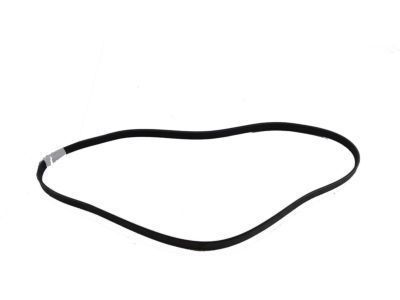

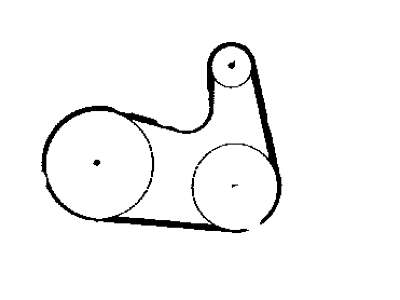

The Drive Belt in Toyota Yaris series of automobiles is instrumental in other parts like the alternator and the A/C compressor to be powered by the engine. Usually, these parts are linked by a serpentine belt that drives the belt and transitions them to the crankshaft pulley. The Driving Belts into Yaris car's are usually expected to works for approximately 100,000miles before they are require to be replaced to avoid further harm to both the parts and the engine. Belts are elastic bands applied in mechanical applications so that they can connect shafts and transmit movement proficiently; there are several groups including V-belts' type and timing belts, which have enhanced grip, endurance, and no-slip features. These advancements have therefore adopted the Drive Belt as a significant component with automobile production.

If you are in demand for superior quality and affordable OEM Toyota Yaris Drive Belt, then shop with us! We own a wide range of the reduced-priced genuine Toyota Yaris Drive Belt. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Yaris Drive Belt Parts Questions & Experts Answers

- Q: How to Operate the Drive Belt on Toyota Yaris?A:To install a Drive Belt, have a wrench, socket set, pry bar, and new belt on hand. Loosen the tensioner pulley, install a new belt using the correct diagram for routing, apply tension with the bar, and tighten the pulley. Check alignment and ensure the belt is seated properly on all pulleys.

- Q: How to Inspect and Maintain the Drive Belt on a Toyota Yaris?A:A single auxiliary drivebelt is fitted at the right-hand side of the engine. The length of the drivebelt varies according to whether power steering or air conditioning is fitted. A manual tensioner is fitted, so the drivebelt tension should be checked at regular intervals and particularly after fitting a new drivebelt. Due to their function and material makeup, drivebelts are prone to failure after a long period of time, and should therefore be inspected regularly. The drivebelt is located very close to the right-hand side of the engine compartment, and better access can be gained by jacking up the right-hand front wheel and removing the engine right-hand lower cover panel. With the engine stopped, inspect the full length of the drivebelt for cracks and separation of the belt plies. Twist the belt between the pulleys to check its condition. Also check for fraying and glazing which gives the belt a shiny appearance. Check the pulleys for nicks, cracks, distortion, and corrosion. Small cracks in the belt ribs are not usually serious, but look closely to see whether the crack has extended into the belt plies. If the belt is in any way suspect or is known to have seen long service, renew it. Check the drivebelt tension by pressing on the belt at a point midway on the longest run between two pulleys. Compare the deflection noted with the figures quoted in the Specifications. If the drivebelt appears excessively taut or slack, adjust the belt tension. If the belt appears not to be too slack but has actually been slipping in service, check the belt for any sign of external contamination and cure the source of the leak before fitting a new belt.

- Q: How to Remove the Drive Belt on a Toyota Yaris?A:Jack up the right front wheel and support the car. Remove the engine's lower cover panel. Loosen the alternator's pivot and lockbolt, unscrew the adjuster bolt, and push the alternator to release the drivebelt. Note the belt's routing as you remove it from the pulleys. For hydraulic power steering models, loosen the adjuster bolt and pivot bolt, then remove the belt from the pump and crankshaft pulleys. Refit the belt onto the pulleys, with the alternator pulley last. Loosen the adjuster bolt if needed to fit a new belt. Tighten the adjuster bolt to remove slack, then adjust the belt tension. Check tension by pressing on the belt. Repeat until satisfactory. Tighten the lockbolt and pivot bolt to the specified torque. Lower the car and check for slipping. If a new belt was fitted, recheck tension after a month or 1000 kilometers.