My Garage

My Account

Cart

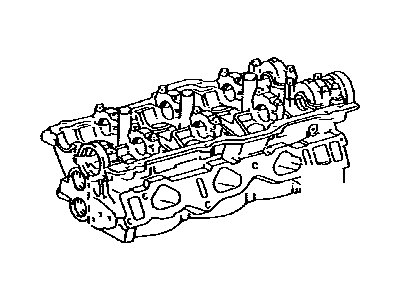

Genuine 2002 Toyota Tacoma Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Cylinder Heads found

2002 Toyota Tacoma Cylinder Head Sub-Assembly

Part Number: 11101-79266$1128.58 MSRP: $1433.11You Save: $304.53 (22%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Sub-Assy, Cylinder; Cylinder Head

- Replaces: 11101-79265

- Part Name Code: 11101

- Item Weight: 27.30 Pounds

- Item Dimensions: 21.9 x 12.7 x 11.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11101-79266

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

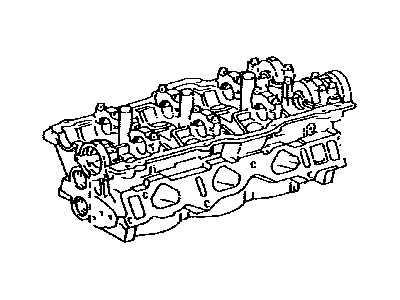

2002 Toyota Tacoma Cylinder Head Sub-Assembly

Part Number: 11101-69135$1083.80 MSRP: $1376.25You Save: $292.45 (22%)Product Specifications- Other Name: Head Sub-Assy, Cylinder

- Replaced by: 11101-69136

- Part Name Code: 11101

- Item Weight: 25.80 Pounds

- Item Dimensions: 21.9 x 12.6 x 10.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 11101-69135

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2002 Toyota Tacoma Cylinder Head

With ToyotaPartsDeal.com, you have access to an extensive inventory of genuine 2002 Toyota Tacoma Cylinder Head, all priced competitively. Feel secure in your purchase, as all our OEM 2002 Toyota Tacoma Cylinder Head are covered by the manufacturer's warranty. Plus, we offer a hassle-free return policy and speedy delivery service.

2002 Toyota Tacoma Cylinder Head Parts Questions & Experts Answers

- Q: How to thorough clean and inspect of cylinder heads and valve components during an engine overhaul for the 2002 Toyota Tacoma?A: Cleaning the cylinder head(s) including the required valve train parts, then examining the parts in detail, will allow you; determine how much valve related work will be required during the engine rebuild. If the engine was severely overheated, the cylinder head is certainly warped. Clean off all the remnants of the old gasket and the sealing compound off the head gasket, the intake manifold, and the exhaust manifold sealing surfaces but ensure that you do not scratch the cylinder head. Some of the gasket removing solutions can be bought at auto parts stores, and their use when removing the gaskets makes the process easier. Deprone all the accumulated scale from the passageway for the coolant as well as the flow channel and run a hard wire brush through all the various holes in an effort to get rid of deposits. If very thick rust deposits are present in the water passages, where the head is exposed, one should have the bare coffee head professionally cleaned at the machine shop. For each of the threaded holes this is done by running an appropriate size tap to clear holes of corrosion and thread sealant also clear holes of debris using compressed air. After that, navigate the wire brush into the exhaust and intake manifold stud threads then clean the cylinder head with solvent and compressed air make the drying process faster. The use of decarbonizing chemicals may be advisable during the cleaning of cylinder heads and the valve train parts but should be administered carefully. Wipe the lifters with solvent and then allow them to dry but at the same time ensure that they are not interchanged. Thoroughly clean all valve springs, spring seats, keepers and retainer using solvent on one valve at a time excluding mixing of parts. Remove any thick layers on the valves, and with the help of a wire brush motorized clean the heads and stems of the valves, so that they are placed in order. Be sure to check the head for cracks, signs of coolant leakage and other signs of damage, should the head be cracked it is recommended that you seek the help of an automotive machine shop. The head gasket mating surface should be checked for the warpage using a straightwire and feeler gauge and if the warpage is off this should be taken to an automotive machine for facing. Inspect the valve seats on each combustion chamber for such conditions as pitting, cracking or burning for they are beyond the home mechanics' repairs. Confirm the valve stem to the guide clearance with a small hole gauge and measure the micrometer while confirming the valve stem deflection using the dial indicator. Each valve face to be examined for end wear, distortion, cracks or pits, signs of severe burning to be looked for and each valve stem to be examined for scuffing or galling. Check the margin width on each valve and make sure that it lies within the set standards. Look at every valve spring for wear and pits, pull through the free length measurement and ensure that any spring which has a free length lesser than the specified amount is discarded. All springs should also be checked in terms of pressure before they can be recommended for use in the rebuilt engine. Over each spring used, stand on a flat surface annually and ensure it is square; if the spring is distorted or sagged, replace it with the correct one. Check the spring retainers and keepers for wear and crack and rebuild them for potential large failure during the running of the engine. Any worn out or worn beyond limits of serviceability must be substituted with new ones; if the check reveals that general condition of the valve components is rather poor, assembled the valves in the cylinder head and proceed with the valve servicing as is advised.