My Garage

My Account

Cart

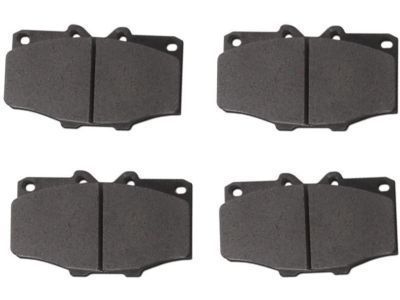

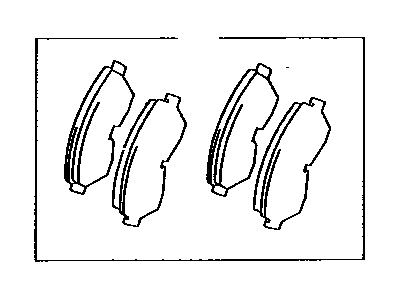

Genuine Toyota 4Runner Brake Pad Set

Disc Brake Pad Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Brake Pad Sets found

Toyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35290$74.93 MSRP: $104.50You Save: $29.57 (29%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Kit

Part Number: 04465-60320$74.93 MSRP: $104.50You Save: $29.57 (29%)Toyota 4Runner Rear Disc Brake Pad Kit

Part Number: 04466-60140$52.35 MSRP: $72.80You Save: $20.45 (29%)Toyota 4Runner Rear Disc Brake Pad Kit

Part Number: 04466-60090$52.11 MSRP: $72.48You Save: $20.37 (29%)Ships in 1-3 Business DaysToyota 4Runner Disc Brake Pad Kit

Part Number: 04465-35330$79.00 MSRP: $111.37You Save: $32.37 (30%)Ships in 1-2 Business DaysToyota 4Runner Front Disc Brake Pad Kit

Part Number: 04465-35240$74.93 MSRP: $104.50You Save: $29.57 (29%)Ships in 1 Business DayToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35230$74.93 MSRP: $104.50You Save: $29.57 (29%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35170$62.96 MSRP: $88.75You Save: $25.79 (30%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35040$67.48 MSRP: $95.13You Save: $27.65 (30%)Ships in 1-3 Business DaysToyota 4Runner Disc Brake Pad Kit

Part Number: 04465-35260$50.44 MSRP: $70.45You Save: $20.01 (29%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35190$74.93 MSRP: $104.50You Save: $29.57 (29%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35140$67.01 MSRP: $94.46You Save: $27.45 (30%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-22090$65.24 MSRP: $91.97You Save: $26.73 (30%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04491-35160$67.48 MSRP: $95.13You Save: $27.65 (30%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04491-35220$45.11 MSRP: $63.08You Save: $17.97 (29%)Ships in 1-2 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35031$50.44 MSRP: $70.45You Save: $20.01 (29%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04465-35020$59.46 MSRP: $83.85You Save: $24.39 (30%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04491-60010$62.96 MSRP: $88.75You Save: $25.79 (30%)Ships in 1-3 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04491-35101$62.96 MSRP: $88.75You Save: $25.79 (30%)Ships in 1-2 Business DaysToyota 4Runner Front Disc Brake Pad Set

Part Number: 04491-35150$43.59 MSRP: $60.95You Save: $17.36 (29%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 43 Results

Toyota 4Runner Brake Pad Set

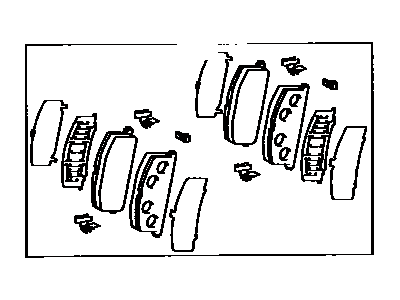

Toyota 4Runner Brake Pad Set are the car parts that enable creation of friction to the brake rotors to bring the car to a halt. These are pads made from friction compounds fastened on a metal backing plate; they like all other kinds are consumed through usage due to the natural wearing off of materials. It is worth listing that many 4Runner models have standard wear sensors or indicators that signal when pads' thickness is low and, thus, they should be replaced. Year after year, several styles of Brake Pad Set have been used on Toyota 4Runner: non-metallic, semi-metallic, and ceramic. All three types have their special benefits in relation to amount of friction, wear and tear and level of noise. Correct care, including the change of related equipment such as clips and springs, is important for the functionality and the durability of the brake pads and should be done approximately every 50,000 miles.

If you are in demand for superior quality and affordable OEM Toyota 4Runner Brake Pad Set, then shop with us! We own a wide range of the reduced-priced genuine Toyota 4Runner Brake Pad Set. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota 4Runner Brake Pad Set Parts Questions & Experts Answers

- Q: How to replace the front brake pad set on fixed and floating calipers for a 2003-2009 Toyota 4Runner?A:Take off the cap for the brake fluid, and then, drain the existing liquid about one-and-a-half inches or 40mm and dispose it effectively. Lose the wheel lug nuts, lift and safely jack up this car, then, place it on suitable stands before removing the wheels. Place a drain pan beneath the brake caliper assembly and wash the disc together with the caliper with the brake system cleaner, guaranteeing that you do this without the use of compressed air. Look at the Brake Disc and if it has to be machined, remove the disc together with the calipers and pads. When it comes to fixed calipers, please refer to the pad replacement illustrated here, where the caliper is dismantled and retaining clips, shrouded anti-rattle springs and pad pins pulled out are removed. The brake pads need to be pushed inward to force the pistons back, after that backplates and contact surfaces have to be cleaned, new pads have to be lubricated and put back on with shims if needed. For floating calipers, retract the piston back into the bore with the help of C- clamp; make sure that the master cylinder's fluid does not spill over. Pull out the caliper, pads and the support plates but while replacing the parts that have worn out and lubricant the new ones before fitting. Replace the new pads as the next step after removing the wheel and lug nuts, put back the wheel and the lug nuts, lower the car, and finally, tighten the lug nuts. Crank the engine and apply the brake pedal several times for the pads to contact the discs, then inspect brake fluid level, and add it if necessary, for proper braking before operating the vehicle.

Related Toyota 4Runner Parts

Browse by Year

2024 Brake Pad Set 2023 Brake Pad Set 2022 Brake Pad Set 2021 Brake Pad Set 2020 Brake Pad Set 2019 Brake Pad Set 2018 Brake Pad Set 2017 Brake Pad Set 2016 Brake Pad Set 2015 Brake Pad Set 2014 Brake Pad Set 2013 Brake Pad Set 2012 Brake Pad Set 2011 Brake Pad Set 2010 Brake Pad Set 2009 Brake Pad Set 2008 Brake Pad Set 2007 Brake Pad Set 2006 Brake Pad Set 2005 Brake Pad Set 2004 Brake Pad Set 2003 Brake Pad Set 2002 Brake Pad Set 2001 Brake Pad Set 2000 Brake Pad Set 1999 Brake Pad Set 1998 Brake Pad Set 1997 Brake Pad Set 1996 Brake Pad Set 1995 Brake Pad Set 1994 Brake Pad Set 1993 Brake Pad Set 1992 Brake Pad Set 1991 Brake Pad Set 1990 Brake Pad Set 1989 Brake Pad Set 1988 Brake Pad Set 1987 Brake Pad Set 1986 Brake Pad Set 1985 Brake Pad Set 1984 Brake Pad Set