My Garage

My Account

Cart

Genuine Toyota Avalon Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Brake Boosters found

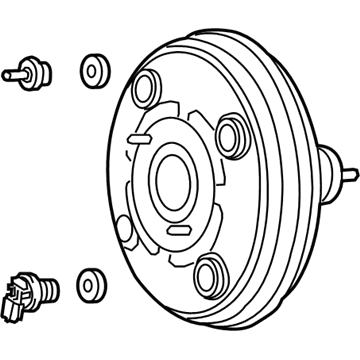

Toyota Avalon Brake Booster Assembly

Part Number: 44610-06670$588.96 MSRP: $879.40You Save: $290.44 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07131$706.71 MSRP: $1055.21You Save: $348.50 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07110$709.50 MSRP: $1059.38You Save: $349.88 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-06761$702.03 MSRP: $1048.23You Save: $346.20 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07112$676.63 MSRP: $1010.31You Save: $333.68 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07120$749.15 MSRP: $1118.59You Save: $369.44 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07170$565.12 MSRP: $843.81You Save: $278.69 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07140$600.43 MSRP: $896.54You Save: $296.11 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07132$616.70 MSRP: $920.82You Save: $304.12 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-06472$702.03 MSRP: $1048.23You Save: $346.20 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-06760$702.03 MSRP: $1048.23You Save: $346.20 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07130$706.71 MSRP: $1055.21You Save: $348.50 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07111$669.58 MSRP: $999.77You Save: $330.19 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-06471$757.51 MSRP: $1131.07You Save: $373.56 (34%)Ships in 1-3 Business DaysToyota Avalon Brake Booster Assembly

Part Number: 44610-07070$225.40 MSRP: $1334.13You Save: $1108.73 (84%)Ships in 1-2 Business Days

Toyota Avalon Brake Booster

The Toyota Avalon Brake Booster is an important unit that diminishes force required to trigger disc brakes and improving the driver's braking, or better still, the petal operation. The Brake Booster also operates with a vacuum chamber to intensify the hydraulic pressure coming from the master cylinder, thus, increasing the force applied by the driver to the brake pedal. There are two main types of boosters used in Avalon vehicles: vacuum operated boosters and hydraulic boosters. Vacuum boosters work on the draw of vacuum that is created by the engine and the atmospheric pressure while hydraulic boosters work on the force exerted by the hydraulic fluid during the application of brakes. The Brake Booster is pretty much standard and could be faulty at times and when this happens, one has to replace the brake booster or get a new one, or get a completely new repair kit.

If you are in demand for superior quality and affordable OEM Toyota Avalon Brake Booster, then shop with us! We own a wide range of the reduced-priced genuine Toyota Avalon Brake Booster. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Avalon Brake Booster Parts Questions & Experts Answers

- Q: How to operate and check the power brake booster on 2002 through 2006 Toyota Avalon?A:The brake test for Avalon models has two steps: with the engine off, press and release the brake pedal several times to see if the brake distance stays the same, then start the engine and watch how the pedal moves down slightly. The engine needs to run for one or two minutes, then stop. Brake pedal depression brings good news: you've got an effective air seal in your booster. When you start the engine, you must keep the brake pedal depressed for 30 seconds when shutting down, then let go of the pedal. If the pedal move the same amount, you know the booster is sealed properly. Repairing a power brake booster isn't possible, because it has too many components that affect how the brakes work. Get a new or remanufactured unit to replace it. To lift the brake master cylinder, disconnect the electrical connector for the precharge pump when Vehicle Stability Control is present, detach all hoses and bolts, too. Also remove the air cleaner unit, then unplug the vacuum connection from the brake booster. Before starting work, drivers must remove the kick panel underneath, knee bolster, reinforcement brace, and other parts directly near the brake pedal. First, the attaching pin between the brake pedal and booster pushrod gets taken off. Then, two nuts and washers need to come out to detach the brake booster from the firewall. You reinstall the booster by tightening the clevis locknut and mounting nuts to the correct tightening force. When you put a new power brake booster unit in, you need to check and adjust the pushrod clearance first, then set the brake pedal height, make it easy to push down, and clear all air from the system.

Related Toyota Avalon Parts

Browse by Year

2022 Brake Booster 2021 Brake Booster 2020 Brake Booster 2019 Brake Booster 2018 Brake Booster 2017 Brake Booster 2016 Brake Booster 2015 Brake Booster 2014 Brake Booster 2013 Brake Booster 2012 Brake Booster 2011 Brake Booster 2010 Brake Booster 2009 Brake Booster 2008 Brake Booster 2007 Brake Booster 2006 Brake Booster 2005 Brake Booster 2004 Brake Booster 2003 Brake Booster 2002 Brake Booster 2001 Brake Booster 2000 Brake Booster 1999 Brake Booster 1998 Brake Booster 1997 Brake Booster 1996 Brake Booster 1995 Brake Booster