My Garage

My Account

Cart

Genuine Toyota Corolla Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

90 Drive Belts found

Toyota Corolla V-Ribbed Belt

Part Number: 90916-A2016$33.55 MSRP: $46.89You Save: $13.34 (29%)Ships in 1-3 Business DaysToyota Corolla V-Ribbed Belt

Part Number: 90916-02679$29.38 MSRP: $41.07You Save: $11.69 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90080-91139$43.78 MSRP: $61.19You Save: $17.41 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90916-02664$33.07 MSRP: $46.22You Save: $13.15 (29%)Ships in 1-2 Business DaysToyota Corolla V Belt

Part Number: 90916-A2011$39.62 MSRP: $55.37You Save: $15.75 (29%)Ships in 1-3 Business DaysToyota Corolla V-Ribbed Belt

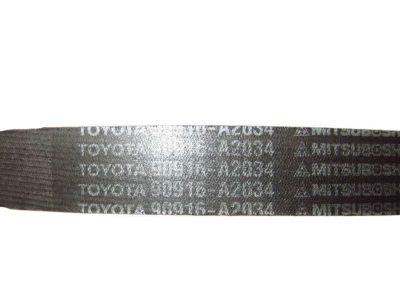

Part Number: 90916-A2034$32.00 MSRP: $44.73You Save: $12.73 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90916-A2018$31.05 MSRP: $43.39You Save: $12.34 (29%)Ships in 1-3 Business DaysToyota Corolla V-Ribbed Belt

Part Number: 90916-A2035$27.00 MSRP: $37.74You Save: $10.74 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90916-02653$39.62 MSRP: $55.37You Save: $15.75 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90916-A2007$47.59 MSRP: $66.52You Save: $18.93 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90916-02354$13.67 MSRP: $19.11You Save: $5.44 (29%)Ships in 1 Business DayToyota Corolla V Belt

Part Number: 90082-93002$15.73 MSRP: $21.98You Save: $6.25 (29%)Ships in 1-3 Business DaysToyota Corolla V-Ribbed Belt

Part Number: 90916-02754$32.00 MSRP: $44.73You Save: $12.73 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90080-91055$17.84 MSRP: $24.93You Save: $7.09 (29%)Ships in 1-3 Business DaysToyota Corolla V-Ribbed Belt

Part Number: 90916-02706$31.05 MSRP: $43.39You Save: $12.34 (29%)Ships in 1-2 Business DaysToyota Corolla V Belt

Part Number: 99365-20970$17.84 MSRP: $24.93You Save: $7.09 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 99332-10860$8.08 MSRP: $11.29You Save: $3.21 (29%)Ships in 1-3 Business DaysToyota Corolla V-Ribbed Belt

Part Number: 90916-A2024$31.05 MSRP: $43.39You Save: $12.34 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90080-91051$7.84 MSRP: $10.96You Save: $3.12 (29%)Ships in 1-3 Business DaysToyota Corolla V Belt

Part Number: 90916-02148$17.60 MSRP: $24.60You Save: $7.00 (29%)Ships in 1-3 Business Days

| Page 1 of 5 |Next >

1-20 of 90 Results

Toyota Corolla Drive Belt

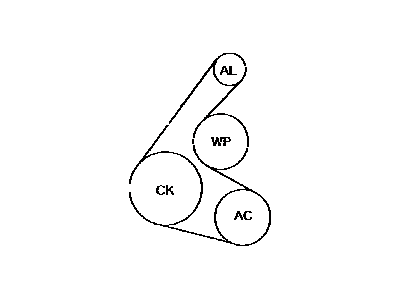

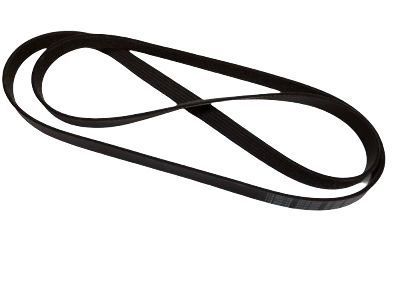

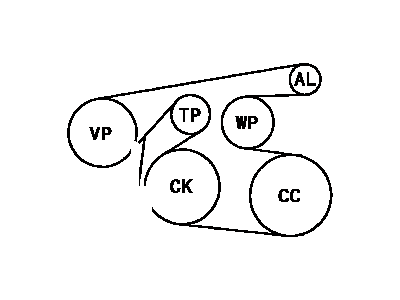

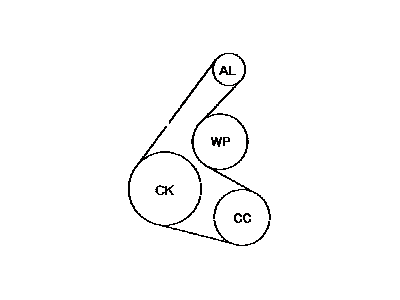

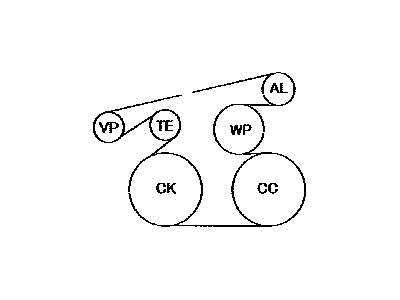

The Drive Belt in Toyota Corolla automobiles is a sprocket-type belt that allows the engine to drive Accsessory equipments including the alternator and A/C compressor. Usually a serpentine belt is applied to link the parts to the crankshaft pulley and other parts in order to guarantee power transmission. In Corolla cars, most Drive Belts have a life span of approximately 100000 miles and a damaged belt poses a serious problem to the engine and parts. There have been occasions where different types of Drive Belts which include V-belts and the timing belt have been used in different Corolla models because of the requirement to cater for a certain type of transmission and need for better traction, durability and non slip feature. These belts have the functionality of maintaining the mechanical performance of the car and its efficiency.

If you are in demand for superior quality and affordable OEM Toyota Corolla Drive Belt, then shop with us! We own a wide range of the reduced-priced genuine Toyota Corolla Drive Belt. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

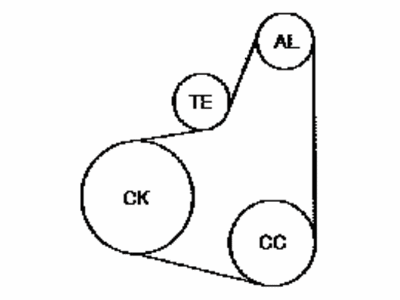

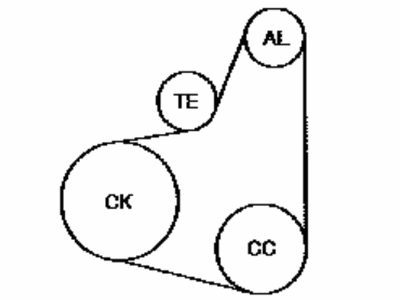

Toyota Corolla Drive Belt Parts Questions & Experts Answers

- Q: How to inspect and replace the Drive Belt on Toyota Corolla?A:The alternator, power steering pump, water pump, and air-conditioning compressor are all driven by one serpentine belt. Due to their composition and the stresses they are subjected to, drive belts stretch and deteriorate as they get older, necessitating periodic inspections. The serpentine belt has no adjustment for tension, unlike older systems with multiple V-belts. The engine has a tensioner that automatically applies the right belt tension and compensates for belt stretch over time. With the engine off, open the hood and locate the drive belt. Using a flashlight, check the belt for various signs of wear and tear. Both sides of the belt should be inspected, which means you will have to twist the belt to check the underside. Use your fingers to feel the belt where you can't see it. If any of the above conditions are evident, replace the belt. Rotate the belt tensioner clockwise to release the tension, then slip the belt off the pulleys and slowly release the tensioner. Route the new belt over the pulleys, again rotating the tensioner to allow the belt to be installed, then release the belt tensioner. Ensure the belt is properly centered in the pulleys. To replace a tensioner that can't properly tension the belt or one that exhibits binding or a worn-out bearing/pulley, remove the drive belt then unscrew the mounting bolt and nut. Installation is the reverse of the removal procedure. Tighten the fasteners to the torque values. Install the drive belt.

Related Toyota Corolla Parts

Browse by Year

2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt 1992 Drive Belt 1991 Drive Belt 1990 Drive Belt 1989 Drive Belt 1988 Drive Belt 1987 Drive Belt 1986 Drive Belt 1985 Drive Belt 1984 Drive Belt 1983 Drive Belt 1982 Drive Belt 1981 Drive Belt 1980 Drive Belt 1979 Drive Belt 1978 Drive Belt 1977 Drive Belt 1976 Drive Belt 1975 Drive Belt