My Garage

My Account

Cart

Genuine Toyota Highlander Fuel Pump

Gas Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Fuel Pumps found

Toyota Highlander Mechanical Fuel Pump Assembly

Part Number: 23101-0P020$888.40 MSRP: $1326.51You Save: $438.11 (34%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump

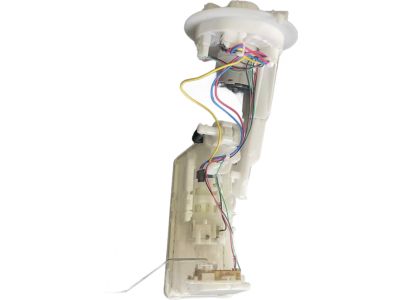

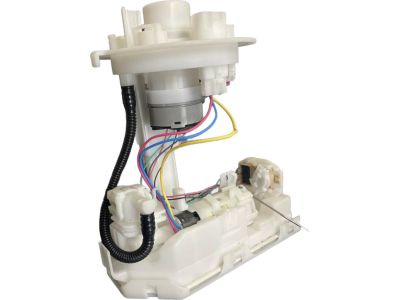

Part Number: 23221-25030$122.69 MSRP: $174.41You Save: $51.72 (30%)Ships in 1-2 Business DaysToyota Highlander Fuel Suction Tube Assembly with Pump & Gage

Part Number: 77020-0E130$356.23 MSRP: $531.42You Save: $175.19 (33%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump Assembly

Part Number: 23220-0P180$335.23 MSRP: $480.70You Save: $145.47 (31%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump Assembly

Part Number: 23221-20030$337.72 MSRP: $503.81You Save: $166.09 (33%)Ships in 1-2 Business DaysToyota Highlander Fuel Pump Assembly with Filter

Part Number: 23220-31180$398.27 MSRP: $594.13You Save: $195.86 (33%)Ships in 1-3 Business DaysToyota Highlander Fuel Suction Tube Assembly with Pump & Gage

Part Number: 77020-0E111$482.78 MSRP: $720.21You Save: $237.43 (33%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump Assembly

Part Number: 77020-0E162$363.59 MSRP: $542.40You Save: $178.81 (33%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump Assembly

Part Number: 23221-62060$354.45 MSRP: $528.76You Save: $174.31 (33%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump

Part Number: 23221-31130$216.33 MSRP: $310.19You Save: $93.86 (31%)Ships in 1-3 Business DaysToyota Highlander Fuel Suction Tube Assembly with Pump & Gage

Part Number: 77020-0E070$553.76 MSRP: $826.84You Save: $273.08 (34%)Ships in 1-3 Business DaysToyota Highlander Fuel Suction Tube Assembly with Pump & Gage

Part Number: 77020-0E021$550.08 MSRP: $821.35You Save: $271.27 (34%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump Sub-Assembly

Part Number: 23101-F0010$888.40 MSRP: $1326.51You Save: $438.11 (34%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump Sub-Assembly

Part Number: 23101-25040$888.40 MSRP: $1326.51You Save: $438.11 (34%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump and Strainer Set

Part Number: 23221-31370$285.58 MSRP: $409.51You Save: $123.93 (31%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump Assembly

Part Number: 23221-75020$332.10 MSRP: $476.20You Save: $144.10 (31%)Ships in 1-3 Business DaysToyota Highlander Fuel Suction Tube Assembly with Pump & Gage

Part Number: 77020-0E090$482.78 MSRP: $720.21You Save: $237.43 (33%)Ships in 1-3 Business DaysToyota Highlander Fuel Pump

Part Number: 23221-25080$269.46 MSRP: $386.38You Save: $116.92 (31%)Ships in 1-2 Business DaysToyota Highlander Electric Fuel Pump Assembly

Part Number: 23221-28020$363.70 MSRP: $542.58You Save: $178.88 (33%)Ships in 1-3 Business DaysToyota Highlander Fuel Suction Tube Assembly

Part Number: 77020-48260$404.18 MSRP: $602.95You Save: $198.77 (33%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 29 Results

Toyota Highlander Fuel Pump

The Toyota Highlander Fuel Pump is pivotal in supplying fuel to the engine to guarantee a proper burning process. It pumps fuel from the tank to the carburetor or the fuel injector if the vehicle uses the fuel injection system and usually contains an electric pump. The other type being mechanical, including diaphragm and plunger types were widely used in carburetor engines unlike at present where electric types are used due to the variety of pressure and efficiency as compared to earlier models. Some of the features of these pumps include the fact that the electronic control units are used in monitoring the safe and efficient delivery off fuel; that direct-injection engines incorporate high-pressure pumps using advanced configurations for enhancement of performance as well as cutting on emissions. Fuel pump whether required for a new fuel module or for getting a high flow pump for more horsepower is crucial for providing the engine with the requisite fuel quantity and pressure.

If you are in demand for superior quality and affordable OEM Toyota Highlander Fuel Pump, then shop with us! We own a wide range of the reduced-priced genuine Toyota Highlander Fuel Pump. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Highlander Fuel Pump Parts Questions & Experts Answers

- Q: How to remove and install a fuel pump and Fuel Level Sensor on Toyota Highlander?A:This procedure depicts a typical pump used on 2003 and earlier models. The pump used on later models is slightly different. Remove the rear seat. Note that on 2007 and later models, once the rear seats are removed from the vehicle it will be necessary to disassemble the rear section components and lift the carpet to gain access to the fuel pump module cover. Remove the fuel pump/Fuel Level Sensor floor service hole cover by carefully prying it out with a screwdriver. Relieve the fuel system pressure and remove the fuel tank cap. Disconnect the fuel pump electrical connector by depressing the release tab and pulling up. Disconnect the cable from the negative battery terminal. Disconnect the fuel supply line from the top of the fuel pump unit by removing the clip and pulling the fitting straight up. Before reconnecting the fitting, inspect the O-ring inside the fitting and replace if damaged. Remove the retaining bolts from the fuel pump/Fuel Level Sensor mounting flange on 2006 and earlier models, or remove the retaining ring on 2007 and later models using a special tool. Carefully lift the fuel pump/Fuel Level Sensor assembly from the fuel tank, angling it to protect the fuel inlet strainer and the Fuel Level Sensor float. Inspect the fuel pump inlet strainer for contamination and clean if necessary. When installing the retaining ring on 2007 and later models, align the triangle mark on the retaining ring with the "S" mark on the fuel tank and tighten 1-1/2 turns. The triangle mark must be positioned between the MIN and MAX marks on the fuel tank. The remainder of installation is the reverse of removal.

- Q: How to perform general checks fuel system, including assessing fuel pump operation and conducting a fuel pressure check on Toyota Highlander?A:To perform general checks on the fuel system, first ensure that there is enough fuel in the Fuel Tank. Then, verify that the fuel pump is running by having an assistant turn the ignition switch to ON and listening for a whirring noise indicating the pump is pressurizing the system. If there is no sound, check the EFI fuse and the circuit opening or EFI relay. If these are fine, check the wiring back to the fuel pump. If voltage is present at the fuel pump connector, the pump is defective, but if there is no voltage, the PCM may be faulty. For a fuel pump pressure check, relieve the fuel system pressure. For four-cylinder models, a fuel pressure gauge and T-fitting are needed to measure the pressure. Disconnect the fuel supply line from the Fuel Rail and connect the gauge between the line and the rail using the T-fitting. For V6 models, a fuel pressure gauge, hose, and adapter are required. Remove the engine cover and unscrew the banjo bolt securing the crossover line to the front fuel rail. Screw the adapter into the rail and connect the fuel pressure test hose. For 2GR-FKS engines, disconnect the low-pressure side fuel delivery line and connect a special service tool between the connections. With the engine off, turn the ignition switch to ON and note the reading on the gauge. Start the engine and check if the pressure remains the same. If the pressure is not within specifications, check the fuel pressure regulator, fuel line, and fuel filter. If necessary, replace the fuel pressure regulator and pump. Leaking Fuel Injectors could also cause low pressure. After testing, relieve the pressure, reconnect the fuel line or crossover line, and check for leaks when starting the engine.

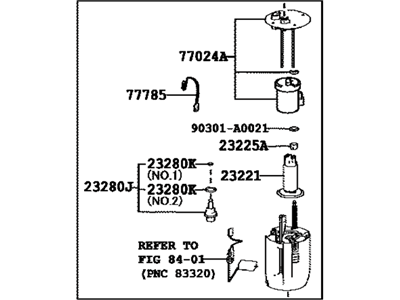

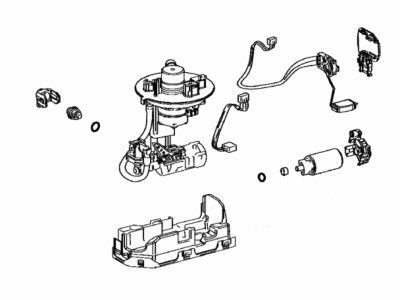

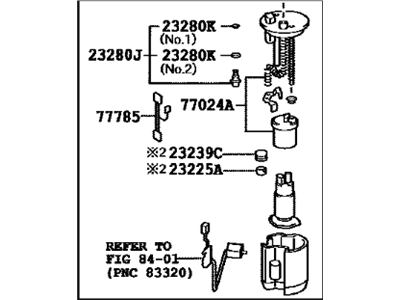

- Q: How to Disassemble the Fuel Level Sensor and Fuel Pump on a Toyota Highlander?A:To replace or repair the components of a fuel pump/Fuel Level Sensor, start by removing the Fuel Level Sensor from the fuel tank and draining residual gasoline. For models up to 2007 (excluding 2007 RX 350), carefully pry off the end cap and remove the rubber insulator, fuel pump inlet strainer, fuel pressure regulator, fuel return jet tube assembly, and fuel pump from the fuel filter assembly. Then, separate the fuel filter housing and detach the Fuel Level Sensor from the upper part of the pump assembly. For installation, reverse the disassembly process. For 2007 RX 350 and models from 2008 onwards, the components are modular. Disconnect the fuel sender electrical connector to remove the Fuel Level Sensor, and disconnect the fuel pump electrical connector to remove the fuel pump. Additionally, remove and inspect the strainer for contamination. For 2GR-FKS models, remove the fuel pump module and the hairpin clip from the module body, and then pull the main valve from the module body. Replace the O-ring on the main valve, lubricate it with clean fuel, and press it into its original bore. Reinstall the hairpin clip and complete the remaining assembly in reverse order.

- Q: How to remove and replace a direct injection 2GR-FKS model's fuel pump on Toyota Highlander?A:First of all, to replace the fuel pump, relieve the fuel system pressure, disconnect the battery, remove the intake manifold, undo the electrical connector attached to the high-pressure fuel pump, and remove the wiring harness bracket, and the fuel line. Use a wrench to remove the high-pressure tube, but when you are loosening the bolts, take caution due to the intense pressure. Then, remove the lifter guide, the spacer gasket, and the O-ring. For the installation process, mount an O-ring onto the pump and rotate the crankshaft to the proper position. Then, install the lifter and guide it into the housing, align the key to the groove, install the spacer gasket and lifter guide to the valve cover, and line up the fuel pump bolt holes. Also, before fully tightening the high-pressure fuel pump bolts they should be tightened by hand, and install the high-pressure fuel tube. Finally, you can tighten the high-pressure fuel pump mounting bolts and the fuel tube nuts to the proper torque.

Related Toyota Highlander Parts

Browse by Year

2024 Fuel Pump 2023 Fuel Pump 2022 Fuel Pump 2021 Fuel Pump 2020 Fuel Pump 2019 Fuel Pump 2018 Fuel Pump 2017 Fuel Pump 2016 Fuel Pump 2015 Fuel Pump 2014 Fuel Pump 2013 Fuel Pump 2012 Fuel Pump 2011 Fuel Pump 2010 Fuel Pump 2009 Fuel Pump 2008 Fuel Pump 2007 Fuel Pump 2006 Fuel Pump 2005 Fuel Pump 2004 Fuel Pump 2003 Fuel Pump 2002 Fuel Pump 2001 Fuel Pump