My Garage

My Account

Cart

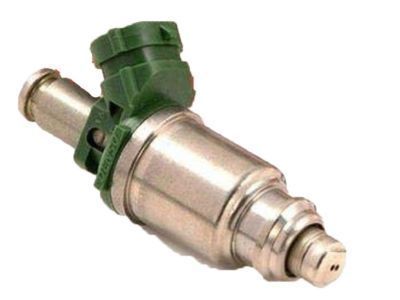

Genuine Toyota MR2 Fuel Injector

Gas Injector- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Fuel Injectors found

Toyota MR2 Fuel Injector Assembly

Part Number: 23209-74100$181.64 MSRP: $260.47You Save: $78.83 (31%)Ships in 1-3 Business Days

Toyota MR2 Fuel Injector

If you are in demand for superior quality and affordable OEM Toyota MR2 Fuel Injector, then shop with us! We own a wide range of the reduced-priced genuine Toyota MR2 Fuel Injector. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota MR2 Fuel Injector Parts Questions & Experts Answers

- Q: How can you remove and install a malfunctioning fuel injector on Toyota MR2?A:It is possible for an injector to pass various tests but still operate improperly; if malfunctioning is suspected despite passing checks, a dealer should perform a volume test, as it requires specialized tools. To test, use an automotive stethoscope to listen to each injector with the engine running, ensuring a steady clicking sound that varies with engine RPM; if a stethoscope is unavailable, feel for vibrations with your finger. Disconnect the electrical connector from the suspect injector and check the resistance with an ohmmeter, which should be between 1.5 to 3.0 ohms; if not, replace the injector. To remove the injector, relieve fuel pressure, disconnect the negative battery terminal, and disconnect the throttle return spring. Use a screwdriver to pop the throttle link rod loose, remove the PCV hose, and disconnect electrical connectors from the fuel injectors and the cold start injector vacuum switching valve. Remove the VSV hose and disconnect the fuel return line from the pressure regulator, then remove the pulsation damper and disconnect the fuel inlet hose from the fuel rail. Remove the banjo bolt and disconnect the cold start injector pipe from the fuel rail, then take out the three fuel rail mounting bolts, carefully pulling the fuel rail free from the cylinder head while ensuring the injectors do not fall out. Use a side-to-side rocking motion to extract the faulty injector from the fuel rail. For installation, replace the O-ring seal whether installing a new injector or fixing a leaking one, applying a light coat of gasoline to the O-ring before inserting the injector back into the fuel rail, ensuring it rotates smoothly. Lubricate the injector nozzle insulators with a little engine oil for easier insertion into the cylinder head, and follow the reverse order of removal for installation, tightening the fuel rail bolts and pulsation damper to the specified torque.