My Garage

My Account

Cart

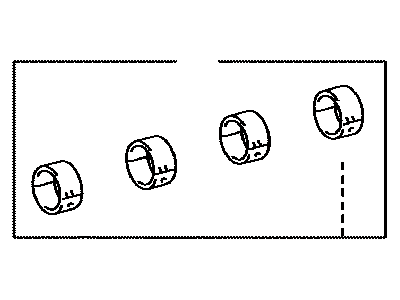

Genuine Toyota MR2 Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Rod Bearings found

Toyota MR2 Connecting Rod Bearing Set

Part Number: 13204-88360$61.47 MSRP: $86.65You Save: $25.18 (30%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-88360-01$13.55 MSRP: $18.95You Save: $5.40 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing Set

Part Number: 13204-74030$59.46 MSRP: $83.82You Save: $24.36 (30%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-16070-02$12.25 MSRP: $17.11You Save: $4.86 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-88360-02$13.55 MSRP: $18.95You Save: $5.40 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-88360-03$13.55 MSRP: $18.95You Save: $5.40 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-16040-02$13.44 MSRP: $18.78You Save: $5.34 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-74030-02$15.82 MSRP: $22.10You Save: $6.28 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-16070-01$10.58 MSRP: $14.78You Save: $4.20 (29%)Toyota MR2 Connecting Rod Bearing

Part Number: 13041-16040-03$13.44 MSRP: $18.78You Save: $5.34 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-16040-01$13.44 MSRP: $18.78You Save: $5.34 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing Set

Part Number: 13204-16040$50.33 MSRP: $70.34You Save: $20.01 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-74030-03$15.82 MSRP: $22.10You Save: $6.28 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing Set

Part Number: 13204-16070$59.13 MSRP: $82.66You Save: $23.53 (29%)Ships in 1-3 Business DaysToyota MR2 Connecting Rod Bearing

Part Number: 13041-16070-03$10.58 MSRP: $14.78You Save: $4.20 (29%)

Toyota MR2 Rod Bearing

The Toyota MR2 Rod Bearing is one of the highly important parts that have the functionality of improving the performance and durability of Toyota MR2 vehicles. Located between the crankshaft and connecting rods, the function of the Rod Bearing is to resist rotation and to minimize friction as this affects the the engine efficiently. Comes in both bi-metal and tri-metal types, these Rod Bearing are especially ideal for high speed use, and hence is frequently applied by those who own MR2 cars. The bi-metal variant has an aluminium alloy inner layer and the tri-metal option has a copper alloy inner layer giving stronger fatigue properties. Interchangeability with other MR2 models is evident as the Toyota Rod Bearing can fit the W10, W20, and W30 generations of the car. Owning to its function in improving the efficiency of the engine, it also has a mandate of supporting safety to the vehicle through preserving the proper oil space and smooth lubrication. Some of the unique characteristics that the consumers of Toyota Rod Bearing could find interesting include the larger oil holes and the use of better materials for the construction of the car, thus making it easier for the consumer to have their MR2 vehicle enhanced. Having being proved to offer strength and efficiency, the Toyota MR2 Rod Bearing is still regarded as the key component any MR2 owner needs for his car to gain the much needed capacity and strength.

If you are in demand for superior quality and affordable OEM Toyota MR2 Rod Bearing, then shop with us! We own a wide range of the reduced-priced genuine Toyota MR2 Rod Bearing. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota MR2 Rod Bearing Parts Questions & Experts Answers

- Q: Why is it important to examine Rod Bearings during an engine overhaul on a Toyota MR2?A:While the main and connecting rod bearings should be replaced with the new ones through an engine overhaul process, it is essential to preserve the old bearings for a detailed investigation of the possible problems with the engine. Common causes of bearing failure consist of; inadequate lubrication, contaminants/foreign particles, overloading and corrosion and should be identified and addressed before reconstruction for future occurrence. Regarding the bearings, it should be removed from the engine block and arranged on a flat surface in positions that correspond the crankshaft journal with the identical problem. Foreign material may also be brought into the, engine during its assembly, through the engine's filters or the PCV system, or through the use of reconditioned metal ch Ips and abrasives. These foreign objects may get lodged in the soft bearing material; the larger particle may cut or dig into the bearing and journal. Proper cleaning of all parts and changing of oil and filter should be done, regular as a precaution measure. This condition is caused by insufficient supply of oil due to high temperature, overloading, leakage of oil, or blockage of oil supply channel resulting to bearing material being removed either by wiping or extrusion from the backing and temperatures augmenting inflammation of the steel. Other driving behaviors also impact bearing life; 'luging' the engine establishes high loads which press out the oil film; short runs cause corrosion because condense water and gases do not get burnt and form acids, sludge. Also, wrong installation practices may result in the failure owing to inadequate oil clearance or dirt got trapped behind the inserts, which resulted in high spots in the bearing.