My Garage

My Account

Cart

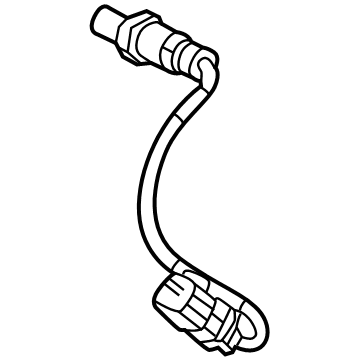

Genuine Toyota Prius Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Oxygen Sensors found

Toyota Prius Air Fuel Ratio Oxygen Sensor

Part Number: 89467-52060$204.50 MSRP: $293.23You Save: $88.73 (31%)Ships in 1-3 Business DaysToyota Prius Oxygen Sensor

Part Number: 89465-47080$134.77 MSRP: $191.61You Save: $56.84 (30%)Ships in 1-3 Business DaysToyota Prius Oxygen Sensor

Part Number: 89465-47070$126.58 MSRP: $179.95You Save: $53.37 (30%)Ships in 1-3 Business DaysToyota Prius Oxygen Sensor

Part Number: 89465-76010$136.29 MSRP: $193.76You Save: $57.47 (30%)Ships in 1-3 Business DaysToyota Prius Air Fuel Ratio Oxygen Sensor

Part Number: 89467-47010$174.34 MSRP: $249.98You Save: $75.64 (31%)Ships in 1-3 Business DaysToyota Prius Air Fuel Ratio Oxygen Sensor No.2

Part Number: 89467-47020$211.22 MSRP: $302.88You Save: $91.66 (31%)Ships in 1-3 Business DaysToyota Prius Air Fuel Ratio Oxygen Sensor

Part Number: 89467-47030$197.88 MSRP: $283.75You Save: $85.87 (31%)Ships in 1-3 Business DaysToyota Prius Oxygen Sensor

Part Number: 89465-47090$133.37 MSRP: $189.60You Save: $56.23 (30%)Ships in 1-3 Business DaysToyota Prius Air Fuel Ratio Oxygen Sensor

Part Number: 89467-28090$198.12 MSRP: $284.09You Save: $85.97 (31%)Ships in 1-3 Business DaysToyota Prius Oxygen Sensor

Part Number: 89465-47060$122.37 MSRP: $173.97You Save: $51.60 (30%)Ships in 1-2 Business DaysToyota Prius Oxygen Sensor

Part Number: 89465-47050$117.40 MSRP: $166.33You Save: $48.93 (30%)Ships in 1-3 Business DaysToyota Prius Air Fuel Ratio Sensor

Part Number: 89467-47040$168.00 MSRP: $238.84You Save: $70.84 (30%)Ships in 1-2 Business DaysToyota Prius Air Fuel Ratio Sensor

Part Number: 89467-47050$188.95 MSRP: $270.94You Save: $81.99 (31%)

Toyota Prius Oxygen Sensor

If you are in demand for superior quality and affordable OEM Toyota Prius Oxygen Sensor, then shop with us! We own a wide range of the reduced-priced genuine Toyota Prius Oxygen Sensor. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Prius Oxygen Sensor Parts Questions & Experts Answers

- Q: What is the general information regarding On-Board Diagnostics 11 (OBD-II) engine management systems and oxygen sensors on Toyota Prius?A:All the vehicles have On-Board Diagnostics 11 (OBD-II) engine management systems to confirm the feedback loop from the oxygen sensor to the ECM by installing sensors at the pre-Catalytic Converter and post-catalytic converter. While the first sensor is installed in the exhaust manifold, the second one is placed behind the catalytic converter; downstream sensor is heated and upstream sensor measures air/fuel ratio. That is, while they look like they do similar functions, the air/fuel sensor puts out a variable voltage signal that is an analog of the actual air/fuel blend in the cylinder, instead of a low voltage signifying lean and a high voltage signifying rich at the stoic point like the oxygen sensor; the air/fuel sensor voltage runs between 3.0 and 3.3 volts, depending on how much oxygen is hanging around During cleaning of these sensors some precautions are needed to avoid damage to the pigtail and the electrical connector, as well as to prevent any contaminants, including cleaning solvents from coming into contact with the part; the position of the silicone boot must also be correct. In the case of Oxygen sensor replacement, a proper procedure should warm the engine to ease pulling off of Oxygen sensor, the second step is to separate the negative terminal for auxiliary battery while the next procedure includes: turning off hybrid high-voltage battery, removing the radiator support cover lastly drain the inverter/converter coolant. Depending on the make, the air/fuel ratio sensor will require removal using the oxygen sensor socket, while the heated oxygen sensor will require unscrewing from the downstream exhaust pipe. Anti-seize compound has to be applied on the threads of the sensor to be installed, the electrical connector has to be connected again and the final step is a test drive to make sure there are no check engine lights on.

Related Toyota Prius Parts

Browse by Year

2024 Oxygen Sensor 2023 Oxygen Sensor 2022 Oxygen Sensor 2021 Oxygen Sensor 2020 Oxygen Sensor 2019 Oxygen Sensor 2018 Oxygen Sensor 2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor 2007 Oxygen Sensor 2006 Oxygen Sensor 2005 Oxygen Sensor 2004 Oxygen Sensor 2003 Oxygen Sensor 2002 Oxygen Sensor 2001 Oxygen Sensor