My Garage

My Account

Cart

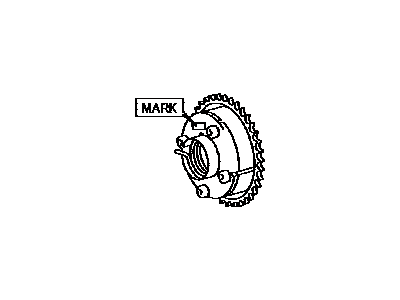

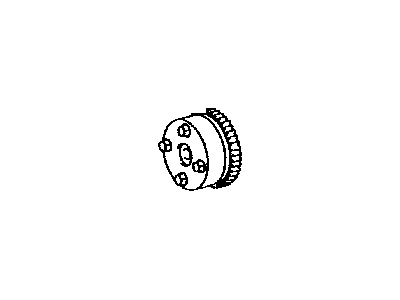

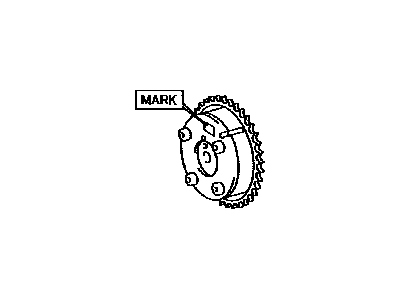

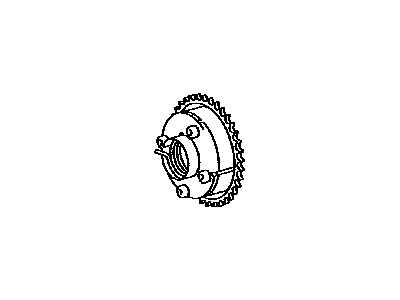

Genuine Toyota Sienna Variable Timing Sprocket

Timing Gear Sprocket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Variable Timing Sprockets found

Toyota Sienna Camshaft Gear Assembly

Part Number: 13050-0V011$324.09 MSRP: $464.73You Save: $140.64 (31%)Toyota Sienna Camshaft Gear Assembly

Part Number: 13070-0V013$347.76 MSRP: $498.66You Save: $150.90 (31%)Toyota Sienna Gear Assy, Camshaft Timing Exhaust, LH

Part Number: 13080-31030$316.55 MSRP: $453.91You Save: $137.36 (31%)Ships in 1-3 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13050-36011$324.09 MSRP: $464.73You Save: $140.64 (31%)Toyota Sienna Camshaft Gear Assembly

Part Number: 13050-36030$259.25 MSRP: $371.75You Save: $112.50 (31%)Toyota Sienna Camshaft Gear Assembly

Part Number: 13080-0P040$315.39 MSRP: $452.25You Save: $136.86 (31%)Ships in 1-3 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13070-36011$347.76 MSRP: $498.66You Save: $150.90 (31%)Ships in 1-2 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13080-31050$315.39 MSRP: $452.25You Save: $136.86 (31%)Ships in 1 Business DayToyota Sienna Camshaft Gear Assembly

Part Number: 13050-31170$280.59 MSRP: $402.35You Save: $121.76 (31%)Toyota Sienna Camshaft Gear Assembly

Part Number: 13070-0V040$315.39 MSRP: $452.25You Save: $136.86 (31%)Toyota Sienna Camshaft Gear Assembly

Part Number: 13070-0P011$373.18 MSRP: $556.71You Save: $183.53 (33%)Ships in 1-2 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13050-0P081$280.59 MSRP: $402.35You Save: $121.76 (31%)Ships in 1-2 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13050-0P071$280.59 MSRP: $402.35You Save: $121.76 (31%)Toyota Sienna Camshaft Gear Assembly

Part Number: 13070-36030$315.39 MSRP: $452.25You Save: $136.86 (31%)Ships in 1-3 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13070-36010$347.76 MSRP: $498.66You Save: $150.90 (31%)Ships in 1-3 Business DaysToyota Sienna Engine Timing Camshaft Gear Assembly

Part Number: 13050-20011$337.50 MSRP: $503.48You Save: $165.98 (33%)Ships in 1 Business DayToyota Sienna Camshaft Gear Assembly

Part Number: 13050-0P070$280.59 MSRP: $402.35You Save: $121.76 (31%)Ships in 1-3 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13070-F0020$175.02 MSRP: $248.82You Save: $73.80 (30%)Toyota Sienna Camshaft Gear Assembly

Part Number: 13050-F0010$408.86 MSRP: $609.94You Save: $201.08 (33%)Ships in 1-3 Business DaysToyota Sienna Camshaft Gear Assembly

Part Number: 13050-0V030$259.25 MSRP: $371.75You Save: $112.50 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 29 Results

Toyota Sienna Variable Timing Sprocket

If you are in demand for superior quality and affordable OEM Toyota Sienna Variable Timing Sprocket, then shop with us! We own a wide range of the reduced-priced genuine Toyota Sienna Variable Timing Sprocket. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Sienna Variable Timing Sprocket Parts Questions & Experts Answers

- Q: How to Check and Replace the Spool Valve and Variable Timing Sprocket on a Toyota Sienna?A:From models manufactured in 2001, Variable Valve Timing (VVT) is incorporated in the assembly, with the control valve being affiliated to the oil system, the oil filter, or the intake Camshaft sprocket/actuator of either cylinder head. The VVT system controls intake camshaft position by regulating the pressure of oil to improve torque, fuel consumption, exhaust emission. Part include PCM; the Oil control valves (OCVs); the oil filters; the intake camshaft sprocket/actuator. The PCM expends signal data from different sensors to regulate the OCV, which disseminates oil pressure to modify the position of the camshaft. Within the sprocket/actuator assembly, there is an internal hub with set vanes which is rotated with the help of oil pressure for the adjustment of up to 21°. In different loads of the engine, the system changes the camshaft timing to increase performance and more efficiency. Problems in the VVT system arise from the OCVs and filters requiring service often. Occasionally, certain OCV filters become clogged which can cause issues, that means the filter needs to be checked and preferably cleaned. It is necessary to check the OCV, for doing this you must measure the resistance across its terminals; if the value is out of the range it should be replaced. For replacement, unplug the electrical connector, and unscrew the hold-down bolt in addition to installing a new O-ring. The camshaft sprocket/actuator assembly thus needs to be well handled, s accepting that it must remain locked at idle conditions. Relatively, the advance side oil port if cleaned and subjected to air pressure, the actuator should move freely; if it fails to do so, replacement is mandatory. In case of replacing the assembly, make sure that the lock pin is aligned to the groove, lubricate the seating plane to the assembly, and use a new retaining nut which is retailed to be turned in the opposite direction. Last but not the least, replace back the intake camshaft, timing belt and finally the valve cover.

Related Toyota Sienna Parts

Browse by Year

2024 Variable Timing Sprocket 2023 Variable Timing Sprocket 2022 Variable Timing Sprocket 2021 Variable Timing Sprocket 2020 Variable Timing Sprocket 2019 Variable Timing Sprocket 2018 Variable Timing Sprocket 2017 Variable Timing Sprocket 2016 Variable Timing Sprocket 2015 Variable Timing Sprocket 2014 Variable Timing Sprocket 2013 Variable Timing Sprocket 2012 Variable Timing Sprocket 2011 Variable Timing Sprocket 2010 Variable Timing Sprocket 2009 Variable Timing Sprocket 2008 Variable Timing Sprocket 2007 Variable Timing Sprocket 2006 Variable Timing Sprocket 2005 Variable Timing Sprocket 2004 Variable Timing Sprocket 2003 Variable Timing Sprocket 2002 Variable Timing Sprocket 2001 Variable Timing Sprocket 2000 Variable Timing Sprocket 1999 Variable Timing Sprocket 1998 Variable Timing Sprocket