My Garage

My Account

Cart

Genuine Toyota Tundra Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

40 Camshafts found

Toyota Tundra Camshaft

Part Number: 13501-50050$487.47 MSRP: $727.20You Save: $239.73 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13054-62030$231.76 MSRP: $332.32You Save: $100.56 (31%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13501-31040$537.83 MSRP: $803.06You Save: $265.23 (34%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13502-62030$231.76 MSRP: $332.32You Save: $100.56 (31%)Ships in 1-3 Business DaysToyota Tundra N Camshaft Sub-Assembly

Part Number: 13053-31090$482.34 MSRP: $719.55You Save: $237.21 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13053-38010$387.90 MSRP: $578.66You Save: $190.76 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13053-62050$336.97 MSRP: $483.19You Save: $146.22 (31%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13501-0F020$426.70 MSRP: $636.55You Save: $209.85 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13502-38010$387.90 MSRP: $578.66You Save: $190.76 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13502-31010$537.83 MSRP: $803.06You Save: $265.23 (34%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13054-31010$537.83 MSRP: $803.06You Save: $265.23 (34%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13053-31010$537.83 MSRP: $803.06You Save: $265.23 (34%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13053-0S010$387.90 MSRP: $578.66You Save: $190.76 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13054-38010$387.90 MSRP: $578.66You Save: $190.76 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13501-0S010$410.31 MSRP: $612.10You Save: $201.79 (33%)Ships in 1-3 Business DaysToyota Tundra N Camshaft Sub-Assembly

Part Number: 13054-31090$482.34 MSRP: $719.55You Save: $237.21 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13502-0S010$387.90 MSRP: $578.66You Save: $190.76 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft Sub-Assembly

Part Number: 13054-0S010$387.90 MSRP: $578.66You Save: $190.76 (33%)Ships in 1-3 Business DaysToyota Tundra Camshaft

Part Number: 13501-38010$410.31 MSRP: $612.10You Save: $201.79 (33%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 40 Results

Toyota Tundra Camshaft

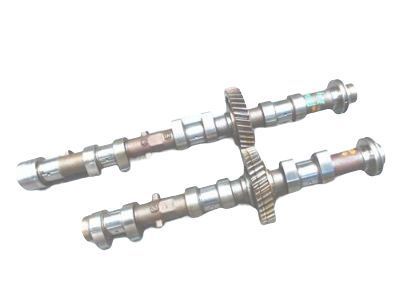

If you are in demand for superior quality and affordable OEM Toyota Tundra Camshaft, then shop with us! We own a wide range of the reduced-priced genuine Toyota Tundra Camshaft. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Tundra Camshaft Parts Questions & Experts Answers

- Q: What are the steps involved in the removal and installation of camshafts in the cylinder heads in 4.7L engine on Toyota Tundra?A:Before performing this procedure get two 6 x 1.0 mm bolts 16 to 20 mm long which are commonly referred to as service bolts. It is recommended to begin with the removal of the valve covers and measuring the lift of the valves and clearance before removing the Timing Belt. If cylinder head work that includes the valves is expected to be carried out, do not measure the clearances at this point. It should be noted that the crankshaft of the specimen must be placed at the angle of 45 degrees TTDC. Next, extract the cam sprockets and the camshaft position sensor out of the engine compartment. For the removal of the camshafts on each cylinder head, firstly locate the right bank cylinder head and make sure that the exhaust camshaft sub-gear is fixed to the driven gear by a service bolt and turn the camshafts in such a manner such that it is in a position that is set approximately 10 degree from the initial position. Position the cam at the top with the two key holes aligned vertically and bring the cam out to contact the drive and driven gears; timing mark on the right side cylinder head should be at an upward 10 degree angle. Turn the camshaft bearing cap bolts by 1/4 turn until they can be undone by hand, in the reverse of the sequence applied. The bearing caps, oil feed pipe and camshafts must be unbolted, lifted using the fingers and placed on a bench with the patented shape end up to reduce the chances of damaging them. The same is done for the left bank cylinder head and the gears are set by camshaft provided that they are not set at a 10 deg angle. Carefully mark each bolt so that you will be able to have them correctly aligned when assembling the bearing caps back again. If necessary, lifters and shims should be removed with a magnetic tool and placed in another place. Screw the hex bolt and remove the timing tube assembly; you also have to release the screw plug, along with its sealing washer while the intake camshaft must be mounted on a vise. To get to the exhaust camshaft, it is possible to eliminate the drive gear from the timing tube assembly which is screwed on four bolts. According to the manual, to disassemble an exhaust camshaft gear, place the cam in a vise and the use the pin spanner to turn the sub-gear clockwise so as to remove the service bolt and the snap ring. The wave washer, sub-gear and camshaft gear spring can then be successfully withdrawn. For installation, use new camshaft plugs in the cylinder head with a little amount of the RTV sealant, new oil seal should be fitted and the drive gear mated to the timing tube. To put the exhaust camshaft gear back in, place all the necessary parts and cover the lifters with grease or engine assembly lube before putting them back in their correct positions. Using a light grade of oil, oil the cam lobes, bearing journals, and tooth faces of the gear, arrange the intake and exhaust camshafts with the timing surfaces set at 10 degrees for the right bank and the same for the left bank. Place RTV sealant on the bearing cap interface componants while the engine is upright, install the bearing caps sequentially, and torque the bolts to 90 degrees in a star pattern. For the service bolt of the exhaust cam gear, remove it and replace the new camshaft oil seal on both the cylinder heads. Replace the timing belt and inspect the valve outcomes; the other parts should also be reinstalled in the reverse manner. Before replacing the valve covers, apply RTV sealant on the surfaces to be connected, and finally replace the cooling system. Then, start the engine and look for evidence of leakage or Signs that the motor is running in the right manner.

Related Toyota Tundra Parts

Browse by Year

2024 Camshaft 2023 Camshaft 2022 Camshaft 2021 Camshaft 2020 Camshaft 2019 Camshaft 2018 Camshaft 2017 Camshaft 2016 Camshaft 2015 Camshaft 2014 Camshaft 2013 Camshaft 2012 Camshaft 2011 Camshaft 2010 Camshaft 2009 Camshaft 2008 Camshaft 2007 Camshaft 2006 Camshaft 2005 Camshaft 2004 Camshaft 2003 Camshaft 2002 Camshaft 2001 Camshaft 2000 Camshaft