My Garage

My Account

Cart

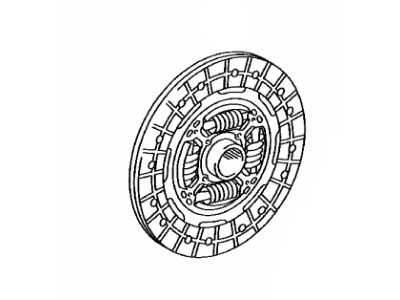

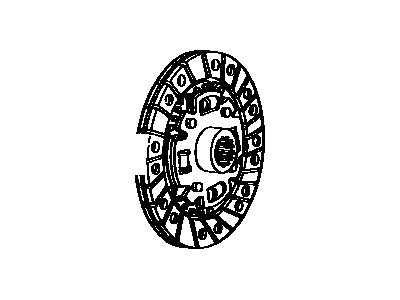

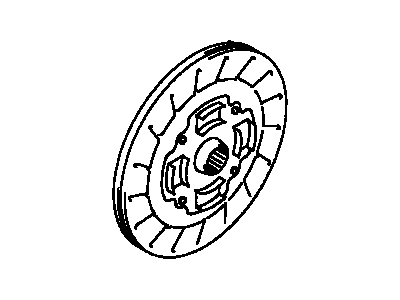

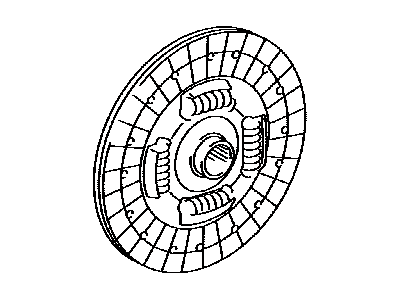

Genuine Toyota Corolla Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

68 Clutch Discs found

Toyota Corolla Clutch Disc Assembly

Part Number: 31250-33040$116.69 MSRP: $164.48You Save: $47.79 (30%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-12360$46.87 MSRP: $65.64You Save: $18.77 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-05101$118.28 MSRP: $168.15You Save: $49.87 (30%)Toyota Corolla Clutch Disc Assembly

Part Number: 31250-02240$140.15 MSRP: $199.25You Save: $59.10 (30%)Ships in 1-2 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-05060$118.28 MSRP: $168.15You Save: $49.87 (30%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc

Part Number: 35633-52020$39.00 MSRP: $54.51You Save: $15.51 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-17020$46.87 MSRP: $65.64You Save: $18.77 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-17010$40.50 MSRP: $56.71You Save: $16.21 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-12670$47.35 MSRP: $66.19You Save: $18.84 (29%)Toyota Corolla Clutch Disc

Part Number: 35633-12080$49.62 MSRP: $69.36You Save: $19.74 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-14090$103.06 MSRP: $145.29You Save: $42.23 (30%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-33041$116.69 MSRP: $164.48You Save: $47.79 (30%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc

Part Number: 35633-33090$54.62 MSRP: $76.34You Save: $21.72 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc

Part Number: 35633-32060$49.62 MSRP: $69.36You Save: $19.74 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-12290$40.50 MSRP: $56.71You Save: $16.21 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-12201$40.50 MSRP: $56.71You Save: $16.21 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc

Part Number: 35667-33020$48.67 MSRP: $68.04You Save: $19.37 (29%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-12021$102.01 MSRP: $143.81You Save: $41.80 (30%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-12040$103.06 MSRP: $145.29You Save: $42.23 (30%)Ships in 1-3 Business DaysToyota Corolla Clutch Disc Assembly

Part Number: 31250-02230$129.27 MSRP: $183.78You Save: $54.51 (30%)

| Page 1 of 4 |Next >

1-20 of 68 Results

Toyota Corolla Clutch Disc

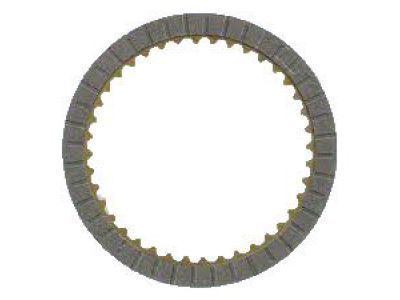

The Clutch Disc in Toyota Corolla performs an essential task by connecting motor power to the input shaft of the transmission to facilitate smooth gearbox operations. The Clutch Disc provides two sides with friction material to enable smooth power transmission by connecting with the flywheel and pressure plate. The clutch pedal button operation triggers the pressure plate unhooking from the Clutch Disc so that gear changes become possible. The Clutch Disc becomes activated after release and enables power to transfer between components. Multiple Toyota Clutch Disc materials such as organic disks alongside ceramic disks and high-performance kevlar and sintered iron options have been employed in Corolla vehicles throughout their history. The regular driving choice features organic Clutch Discs whereas ceramic system parts support performance requirements. The street uses sprung hub designs to minimize shock and motor noise while rigid hub Toyota replacement units remain optimal for competitive racing events. Performance along with durability depends on which Corolla replacement part type is applied since each material presents different heat resistance properties.

If you are in demand for superior quality and affordable OEM Toyota Corolla Clutch Disc, then shop with us! We own a wide range of the reduced-priced genuine Toyota Corolla Clutch Disc. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Corolla Clutch Disc Parts Questions & Experts Answers

- Q: How to remove and inspect of Clutch Disc and Pressure Plate on Toyota Corolla?A:The clutch parts are usually accessed with the transaxle of the vehicle in place, although the engine remains a part of the car. In case of a major overhaul of the engine then the clutch should also be checked for signs of wear and expectedly repairing or replacing damaged parts is best done at this stage since parts of the clutch are relatively cheaper than the time it would take to access the clutch. The following procedures are based on assumed that the engine stays in the car. Start by sliding the release cylinder back and ensure it is out of the way but do not detach the hose. Subsequently, take out the transaxle from the car and make sure that the engine is effectively supported and maybe with an engine lift or support stand. If using a jack place a piece of wood between the jack and the oil pan and be careful as the oil pump pick up is towards the end of the pan and may distort the pan and lead to oil starvation. It is acceptable to leave the release fork and bearing connected to the transaxle for a while longer. For clamping support of the clutch disc, screw in a clutch alignment tool through the disc hub. Search the surface of the flywheel as well as the pressure plate for signs of indexing and in the absence of such signs, make them yourself once you are to reassemble the unit. Lose the pressure plate to the flywheel bolts diagonally, in order to ease the tension of the clutch spring, then take the bolts, then the pressure plate, as well as the clutch disc. While inspecting the engine components, examine the flywheel for presence of any crack or any defect on its surface and it should be corrected by resurfacing if there is any. For the clutch disc lining, see that they are worn by at most 1/32-inch above the rivet heads and appear for any damage. Products like the Release Bearing should be replaced together with the clutch disc. Check pressures of the pressure plate for signs of wear or damage, if worn replace the pressure plate. Several new shells about flywheel and pressure plate: Before the installation the machined surfaces of the flywheel and pressure plate have to be free of oil and grease. Insert the clutch disc on the flywheel with the help of an alignment tool and make sure that the pressure plate is installed in the correct manner. Now again tighten the pressure plate-to-flywheel bolts up to just 'snug' fit, align the clutch disc and then in a cross-hatch sequence tighten these bolts and finally use a torque wrench on them. In the inner groove of the release bearing as well as around the contact surfaces of the release lever and the input shaft bearing retainer apply HTL. The next step is to bolt in the clutch release bearing, the transaxle and the back in the components that were previously removed: everything must be tightened to the recommended torque.

Related Toyota Corolla Parts

Browse by Year

2024 Clutch Disc 2023 Clutch Disc 2022 Clutch Disc 2021 Clutch Disc 2020 Clutch Disc 2019 Clutch Disc 2018 Clutch Disc 2017 Clutch Disc 2016 Clutch Disc 2015 Clutch Disc 2014 Clutch Disc 2013 Clutch Disc 2012 Clutch Disc 2011 Clutch Disc 2010 Clutch Disc 2009 Clutch Disc 2008 Clutch Disc 2007 Clutch Disc 2006 Clutch Disc 2005 Clutch Disc 2004 Clutch Disc 2003 Clutch Disc 2002 Clutch Disc 2001 Clutch Disc 2000 Clutch Disc 1999 Clutch Disc 1998 Clutch Disc 1997 Clutch Disc 1996 Clutch Disc 1995 Clutch Disc 1994 Clutch Disc 1993 Clutch Disc 1992 Clutch Disc 1991 Clutch Disc 1990 Clutch Disc 1989 Clutch Disc 1988 Clutch Disc 1987 Clutch Disc 1986 Clutch Disc 1985 Clutch Disc 1984 Clutch Disc 1983 Clutch Disc 1982 Clutch Disc 1981 Clutch Disc 1980 Clutch Disc 1979 Clutch Disc 1978 Clutch Disc 1977 Clutch Disc 1976 Clutch Disc 1975 Clutch Disc