My Garage

My Account

Cart

Genuine Toyota Prius Variable Timing Sprocket

Timing Gear Sprocket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Variable Timing Sprockets found

Toyota Prius Camshaft Gear Assembly

Part Number: 13050-0T011$259.25 MSRP: $371.75You Save: $112.50 (31%)Ships in 1-2 Business DaysToyota Prius Sprocket, Camshaft Timing

Part Number: 13523-22020$43.66 MSRP: $61.03You Save: $17.37 (29%)Ships in 1-2 Business DaysToyota Prius Gear Assembly, Camshaft Timing

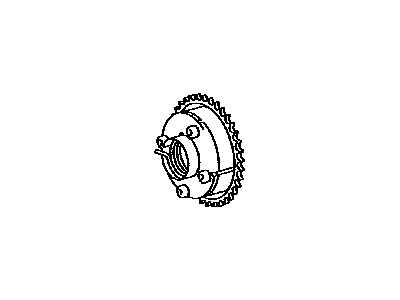

Part Number: 13050-0T010$259.25 MSRP: $371.75You Save: $112.50 (31%)Toyota Prius Gear Assembly, Camshaft Timing

Part Number: 13050-37012$278.97 MSRP: $400.02You Save: $121.05 (31%)Toyota Prius Camshaft Gear Assembly

Part Number: 13050-37040$278.97 MSRP: $400.02You Save: $121.05 (31%)Ships in 1-2 Business DaysToyota Prius Camshaft Gear Assembly

Part Number: 13050-37050$280.36 MSRP: $402.02You Save: $121.66 (31%)Ships in 1-3 Business DaysToyota Prius Camshaft Gear Assembly

Part Number: 13050-25010$408.86 MSRP: $609.94You Save: $201.08 (33%)Ships in 1-3 Business DaysToyota Prius Camshaft Gear Assembly

Part Number: 13070-25030$166.88 MSRP: $237.25You Save: $70.37 (30%)Ships in 1-3 Business DaysToyota Prius Camshaft Gear Assembly

Part Number: 13050-21051$264.47 MSRP: $379.23You Save: $114.76 (31%)Ships in 1-3 Business DaysToyota Prius Camshaft Gear Assembly

Part Number: 13050-0T022$278.97 MSRP: $400.02You Save: $121.05 (31%)Ships in 1-3 Business DaysToyota Prius Gear Assembly Camshaft Timing

Part Number: 13050-21050$264.47 MSRP: $379.23You Save: $114.76 (31%)Ships in 1-3 Business DaysToyota Prius Camshaft Timing Sprocket

Part Number: 13523-21020$46.16 MSRP: $64.52You Save: $18.36 (29%)

Toyota Prius Variable Timing Sprocket

If you are in demand for superior quality and affordable OEM Toyota Prius Variable Timing Sprocket, then shop with us! We own a wide range of the reduced-priced genuine Toyota Prius Variable Timing Sprocket. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Prius Variable Timing Sprocket Parts Questions & Experts Answers

- Q: How to Check the Spool Valve and Variable Timing Sprocket on a Toyota Prius?A:VVT is used on all the models depending on the oil pressure to shift the intake Camshaft sprocket actuator, which improves the power, economy, and emissions under certain situations. They include; the PCM, VVT OCV, OCV filter, and intake camshaft sprocket actuator. PCM turns on the oil control valve depending on signals that several sensors send thus directing the oil pressure to either advance or retard the camshaft. The actuator assembly includes an axillary pin that is used to change the camshaft with the help of oil pressure, and fixed vanes which can rotate the hub in the range of 21 degrees at maximum. A detection procedure of the VVT system includes checking the oil control valve filter for blockage because of problems mainly from the valve and the filter with respect to the oil and filter change. Their performance is checked by using resistance and also checking the movement of the plunger when voltage is being supplied to the oil control valve. The final inspection process entails the valve cover and intake camshaft withdrawal to effect camshaft snout cleaning as well as proper re-assembly of the actuator assembly that has to rotate as a result of air pressure. If any of the components are not working properly then replacements are needed, and the process of reassembling is done in the sequence opposite to the process of disassembling.

Related Toyota Prius Parts

Browse by Year

2024 Variable Timing Sprocket 2023 Variable Timing Sprocket 2022 Variable Timing Sprocket 2021 Variable Timing Sprocket 2020 Variable Timing Sprocket 2019 Variable Timing Sprocket 2018 Variable Timing Sprocket 2017 Variable Timing Sprocket 2016 Variable Timing Sprocket 2015 Variable Timing Sprocket 2014 Variable Timing Sprocket 2013 Variable Timing Sprocket 2012 Variable Timing Sprocket 2011 Variable Timing Sprocket 2010 Variable Timing Sprocket 2009 Variable Timing Sprocket 2008 Variable Timing Sprocket 2007 Variable Timing Sprocket 2006 Variable Timing Sprocket 2005 Variable Timing Sprocket 2004 Variable Timing Sprocket 2003 Variable Timing Sprocket 2002 Variable Timing Sprocket 2001 Variable Timing Sprocket