My Garage

My Account

Cart

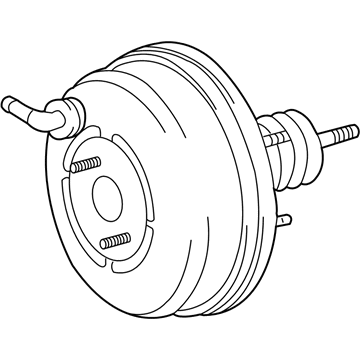

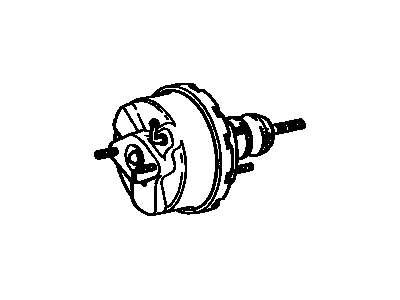

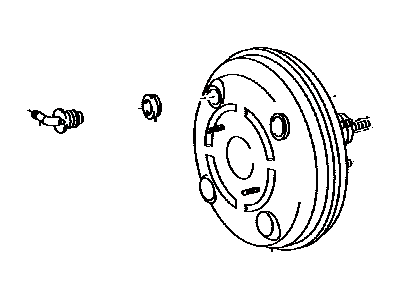

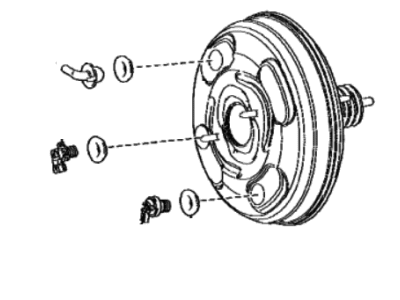

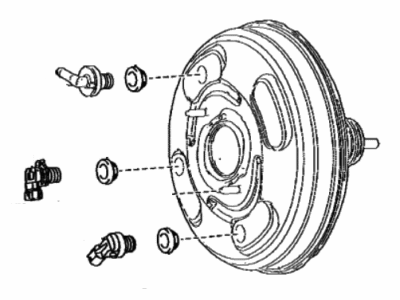

Genuine Toyota RAV4 Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Brake Boosters found

Toyota RAV4 Booster Assembly Brake

Part Number: 44610-0R120$589.85 MSRP: $880.73You Save: $290.88 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-0R060$563.56 MSRP: $841.48You Save: $277.92 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42380$563.56 MSRP: $841.48You Save: $277.92 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42301$674.07 MSRP: $1006.48You Save: $332.41 (34%)Ships in 1-2 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42300$674.07 MSRP: $1006.48You Save: $332.41 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42320$702.81 MSRP: $1049.39You Save: $346.58 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42321$702.81 MSRP: $1049.39You Save: $346.58 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-0R050$563.56 MSRP: $841.48You Save: $277.92 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-0R011$598.21 MSRP: $893.21You Save: $295.00 (34%)Ships in 1-3 Business DaysToyota RAV4 Booster Assembly Brake

Part Number: 44610-0R130$646.67 MSRP: $965.56You Save: $318.89 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42360$563.56 MSRP: $841.48You Save: $277.92 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-0R021$598.21 MSRP: $893.21You Save: $295.00 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42170$662.86 MSRP: $989.74You Save: $326.88 (34%)Ships in 1-3 Business DaysToyota RAV4 Booster Assy, Brake

Part Number: 44610-42500$589.85 MSRP: $880.73You Save: $290.88 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-0R131$588.85 MSRP: $879.23You Save: $290.38 (34%)Ships in 1-3 Business DaysToyota RAV4 Booster Assembly Brake

Part Number: 44610-42510$646.67 MSRP: $965.56You Save: $318.89 (34%)Ships in 1-3 Business DaysToyota RAV4 Brake Booster Assembly

Part Number: 44610-42511$675.07 MSRP: $1007.98You Save: $332.91 (34%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 21 Results

Toyota RAV4 Brake Booster

The Toyota RAV4 Brake Booster is an advanced part that highly contributes to the efficient functionality of the braking system for a splendid driving experience. The Brake Booster is one of the highly trusted brands, which basically functions based on vacuum action, and works through the differential pressure of the engine vacuum and normal atmospheric pressure so as to magnify the force which is applied to the brake pedal. This feature is efficacious primarily in different types of the RAV4 since it lessens the degree of involvement of the driver and in the process enhances safety. Since the early models, the Toyota RAV4 has applied vacuum operated boosters that are known to be very hard wearing though some newer types that include the dual diaphragm boosters enhance performance in confined engine compartments. In this evolution, the Brake Booster also has an important function so that every model of RAV4 has adequate braking force. Speaking of the compatibility that spans multiple RAV4 generations, Toyota Brake Booster is an excellent example of an identically designed part with advanced functionality. Apart from raising the vehicle's efficiency level, it provides a beneficial effect on the safety of drivers and passengers. In summary, the Toyota RAV4 Brake Booster can be described as a product that is typical of the above qualities of the brand and essential for any car owner who wants a reliable and safe RAV4 on the roads.

If you are in demand for superior quality and affordable OEM Toyota RAV4 Brake Booster, then shop with us! We own a wide range of the reduced-priced genuine Toyota RAV4 Brake Booster. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota RAV4 Brake Booster Parts Questions & Experts Answers

- Q: How to operate, check airtightness, remove, and install a power brake booster on Toyota Rav4?A:To perform an operating check, depress the brake pedal several times with the engine off, ensuring no change in the pedal reserve distance, and confirm that the booster reserve vacuum is fully utilized. While holding the pedal down, start the engine; the pedal should fall to the floor. Release the pedal, wait a few seconds, and apply it again to check if it returns to its normal position. If it does not, check the vacuum to the booster; if the vacuum is good, the booster is faulty and should be replaced. For an airtightness check, start the engine and turn it off after one or two minutes, then depress the brake pedal slowly several times; if the pedal depresses less each time, the booster is airtight. With the engine off, pump the brake pedal several times to deplete the vacuum in the power brake booster before removal. The booster units should not be disassembled due to the need for special tools; instead, replace them with new or rebuilt units. Disconnect the negative battery cable, remove the windshield wiper motor, cowl, and Brake Master Cylinder, then disconnect the hose from the engine to the booster, taking care not to damage it. Remove the driver's knee bolster/airbag and the ABS actuator assembly, then take out the pedal return spring and the clevis pin connecting the booster to the brake pedal. Remove the four nuts holding the brake booster to the firewall and slide the booster away until the studs clear the holes. For installation, follow the reverse of removal, ensuring to securely tighten the clevis locknut and booster mounting nuts. If installing a new power brake booster, check the pushrod clearance by measuring the distances from the pushrod to the master cylinder and adjusting as necessary to avoid interference or excessive travel. After installing the master cylinder and brake hoses, adjust the brake pedal height and freeplay, and bleed the system.

Related Toyota RAV4 Parts

Browse by Year

2024 Brake Booster 2023 Brake Booster 2022 Brake Booster 2021 Brake Booster 2020 Brake Booster 2019 Brake Booster 2018 Brake Booster 2017 Brake Booster 2016 Brake Booster 2015 Brake Booster 2014 Brake Booster 2013 Brake Booster 2012 Brake Booster 2011 Brake Booster 2010 Brake Booster 2009 Brake Booster 2008 Brake Booster 2007 Brake Booster 2006 Brake Booster 2005 Brake Booster 2004 Brake Booster 2003 Brake Booster 2002 Brake Booster 2001 Brake Booster 2000 Brake Booster 1999 Brake Booster 1998 Brake Booster 1997 Brake Booster 1996 Brake Booster