My Garage

My Account

Cart

Genuine Toyota RAV4 Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

140 Brake Lines found

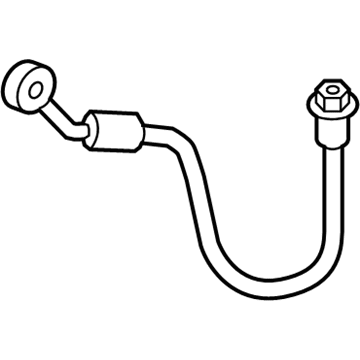

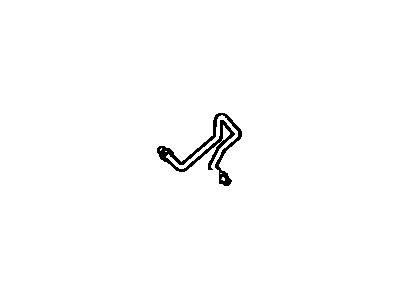

Toyota RAV4 Flexible Hose

Part Number: 90947-02F49$115.98 MSRP: $163.50You Save: $47.52 (30%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02F50$115.98 MSRP: $163.50You Save: $47.52 (30%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02781$81.17 MSRP: $114.42You Save: $33.25 (30%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02782$81.17 MSRP: $114.42You Save: $33.25 (30%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02F52$55.80 MSRP: $78.00You Save: $22.20 (29%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02F51$55.80 MSRP: $78.00You Save: $22.20 (29%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02F47$93.09 MSRP: $131.22You Save: $38.13 (30%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-A2042$121.20 MSRP: $172.31You Save: $51.11 (30%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

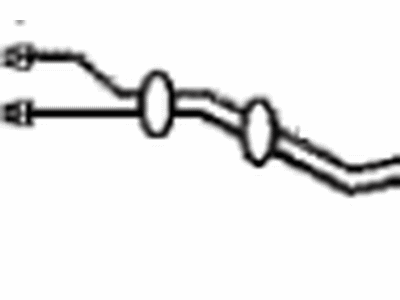

Part Number: 90947-02J08$69.61 MSRP: $98.13You Save: $28.52 (30%)Ships in 1-3 Business DaysToyota RAV4 Rear Brake Tube

Part Number: 47321-42150$51.28 MSRP: $71.68You Save: $20.40 (29%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-A2114$69.61 MSRP: $98.13You Save: $28.52 (30%)Ships in 1-3 Business DaysToyota RAV4 Rear Brake Tube No.1

Part Number: 47321-0R010$51.28 MSRP: $71.68You Save: $20.40 (29%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02C53$57.11 MSRP: $79.83You Save: $22.72 (29%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-02C55$90.38 MSRP: $127.40You Save: $37.02 (30%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-A2079$93.09 MSRP: $131.22You Save: $38.13 (30%)Ships in 1-3 Business DaysToyota RAV4 Rear Brake Tube

Part Number: 47324-42041$13.44 MSRP: $18.78You Save: $5.34 (29%)Ships in 1-3 Business DaysToyota RAV4 Front Brake Tube

Part Number: 47313-42320$24.38 MSRP: $34.08You Save: $9.70 (29%)Ships in 1-3 Business DaysToyota RAV4 Flexible Hose

Part Number: 90947-A2113$69.61 MSRP: $98.13You Save: $28.52 (30%)Ships in 1-3 Business Days

| Page 1 of 7 |Next >

1-20 of 140 Results

Toyota RAV4 Brake Line

If you are in demand for superior quality and affordable OEM Toyota RAV4 Brake Line, then shop with us! We own a wide range of the reduced-priced genuine Toyota RAV4 Brake Line. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota RAV4 Brake Line Parts Questions & Experts Answers

- Q: How to inspect and replace brake hoses and metal brake lines on Toyota Rav4?A:About every six months, with the vehicle raised and supported securely on jackstands, inspect the rubber hoses connecting the steel brake lines to the front and rear brake assemblies for cracks, chafing, leaks, blisters, and other damage, as these are crucial parts of the brake system. Use a light and mirror for a thorough check, and replace any hose showing signs of wear. To replace a disc brake hose, loosen the wheel lug nuts, raise the vehicle, and remove the wheel. Unscrew the brake line fitting from the hose using a flare-nut wrench to avoid rounding off the corners, and hold the hose fitting with an open-end wrench if the bracket bends. Remove the U-clip from the female fitting at the bracket with pliers and pass the hose through the bracket. At the caliper end, remove the banjo fitting bolt and separate the hose, ensuring to replace the two copper sealing washers during installation. Unbolt the hose from the strut bracket if applicable, then install the new hose in reverse order, ensuring it isn't twisted, and securely tighten the banjo bolt and brake hose-to-brake line fitting. After installation, check the master cylinder fluid level, add fluid if necessary, and bleed the brake system before carefully testing the brakes. When replacing metal brake lines, use the correct steel parts and avoid copper tubing. Prefabricated brake lines with flared tube ends and installed fittings are available at auto parts stores and can be bent to the proper shape. Ensure the new line is securely supported in brackets and has adequate clearance from moving or hot components.

Related Toyota RAV4 Parts

Browse by Year

2024 Brake Line 2023 Brake Line 2022 Brake Line 2021 Brake Line 2020 Brake Line 2019 Brake Line 2018 Brake Line 2017 Brake Line 2016 Brake Line 2015 Brake Line 2014 Brake Line 2013 Brake Line 2012 Brake Line 2011 Brake Line 2010 Brake Line 2009 Brake Line 2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line 2003 Brake Line 2002 Brake Line 2001 Brake Line 2000 Brake Line 1999 Brake Line 1998 Brake Line 1997 Brake Line 1996 Brake Line