My Garage

My Account

Cart

Genuine Toyota Supra Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Oil Pans found

Toyota Supra Oil Pan Sub-Assembly

Part Number: 12102-46031$153.73 MSRP: $218.55You Save: $64.82 (30%)Ships in 1-2 Business DaysToyota Supra Oil Pan Sub-Assembly

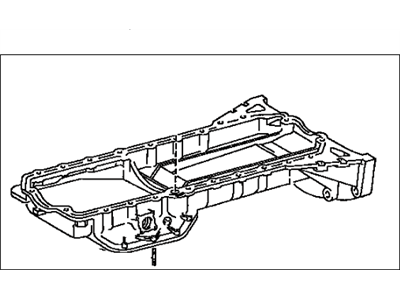

Part Number: 12111-46052$408.97 MSRP: $610.10You Save: $201.13 (33%)Toyota Supra Oil Pan Sub-Assembly

Part Number: 12102-46030$153.73 MSRP: $218.55You Save: $64.82 (30%)Ships in 1-3 Business DaysToyota Supra Oil Pan Sub-Assembly

Part Number: 12111-46051$412.18 MSRP: $614.90You Save: $202.72 (33%)

Toyota Supra Oil Pan

This component guarantees the overall performance and dependability of Toyota Supra also by keeping and helping to protect the engine's lubrication. The Oil Pan is located under the engine below the wet sump system, it stores the oil that is transferred to cool essential engine components through an oil pump. Thus, this design not only eliminates the leakage problem but also ensures precise oil control and which in turn improves the performance and safety of the Toyota Supra. At one point in time, the Supra's Oil Pan was made out of stamped steel, although the new generation of the vehicle has shifted to cast aluminum, which is far more dependable and effective. This change is as a result of Toyota's adherence to engineering principles specifically on the Supra models which include motor trend's import car of the year. With this Oil Pan applying for the A70 and A80 generations, Supra enthusiasts can confidently feel that they can always find a good Oil Pan for their cars no matter which generation they belong to. Furthermore, while the standard wet sump lubrication system can be observed, the features regarding the design of the system for oil supply during extreme cornering indicate the sports orientation of the new Toyota Supra. Being hardwearing and possessing as many extra features, the Oil Pan is unique and unexampled in the context of automotive industry and represents the core values with which Toyota has been supplying the consumers and twingo Supra in particular for decades.

If you are in demand for superior quality and affordable OEM Toyota Supra Oil Pan, then shop with us! We own a wide range of the reduced-priced genuine Toyota Supra Oil Pan. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Supra Oil Pan Parts Questions & Experts Answers

- Q: How to remove and install the oil pan on Toyota Supra?A:Before removing the engine one has to disconnect the negative terminal of the battery and drain the engine oil. For easy working on the area of the oil pan, it is recommended that you lift the vehicle on a jack and put on support stands. Take the bolts out and pull the engine undercover; next grab the exhaust pipe clamp bolt and separate it from the pipe bracket. Subsequently, undo the four retaining bolts of stiffener plates on each side of the engine and pull out the flywheel inspection cover. Place an engine hoist beneath the vehicle and use hooks to hook to the two red clips on the engine at the frame, unscrew the two nuts connecting the engine to the car and slightly lift the engine. Take out the oil pan retaining bolts; if the pan does not come off, use a knife blade and hammer to cut around the gasket and loosen the bond, avoiding to scrape the gasket faces. Installation before cleaning the sealing surfaces, using gasket scraper, remove old gasket material and sealant on the pan and block. To clean the bolt and sealing patterns, you should dip a cloth in lacquer thinner or acetone. Open the oil pan flange and check whether it is distorted and flatten it if so. Put on a new gasket on the pan flange, align the pan and place it over the block, fasten bolts and tighten in sequences, starting with the middle to outward spiral manner. Lastly turn on the engine and look at oil leaks at the lower region of the engine especially at the oil pan.