My Garage

My Account

Cart

Genuine Toyota Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Turbochargers found

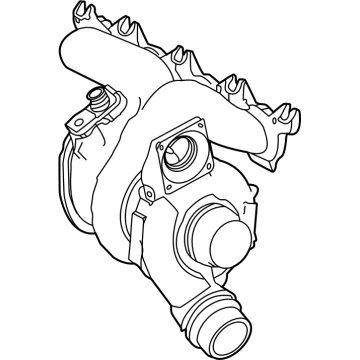

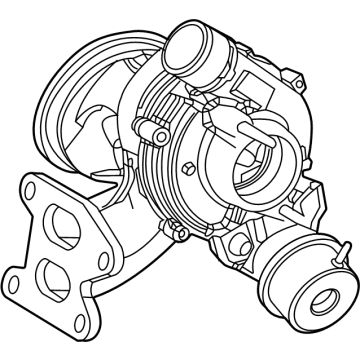

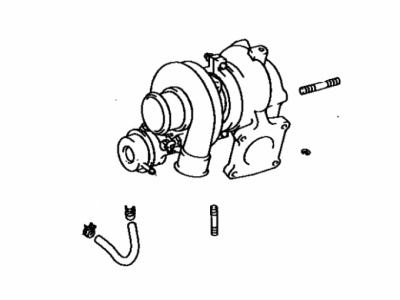

Toyota Turbocharger Sub-Assembly

Part Number: 17201-F4010$2805.15 MSRP: $4188.48You Save: $1383.33 (34%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TURBOCHARGER SUB-ASS; Turbocharger

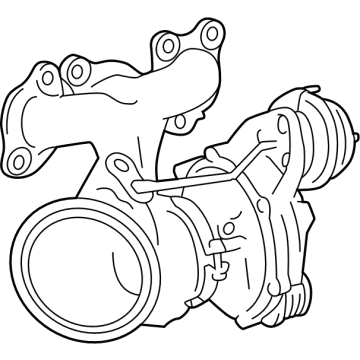

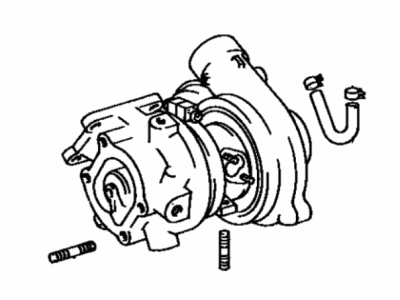

Toyota Turbocharger Assembly

Part Number: 17208-F4010$3079.64 MSRP: $4598.34You Save: $1518.70 (34%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TURBOCHARGER SUB-ASS; Turbocharger

- Replaced by: 17208-70070

Toyota Turbocharger Assembly

Part Number: 17201-WAA02$1247.67 MSRP: $1862.95You Save: $615.28 (34%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TURBOCHARGER SUB-ASS; Turbocharger

- Replaces: 17201-WAA09

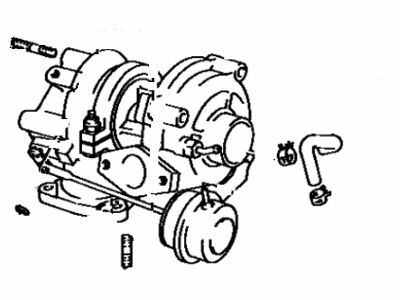

Toyota TURBOCHARGER Sub-Ass

Part Number: 17201-WAA08$1504.70 MSRP: $2246.72You Save: $742.02 (34%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Turbocharger

Toyota ACTUATOR & Link Assembly

Part Number: 17240-WAA01$224.43 MSRP: $321.80You Save: $97.37 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Wastegate

Toyota TURBOCHARGER Sub-Ass

Part Number: 17201-WAA03$1301.93 MSRP: $1943.97You Save: $642.04 (34%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Turbocharger

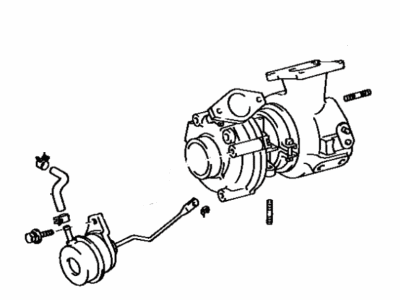

Toyota Turbocharger Sub-Assembly

Part Number: 17201-25010$2423.50 MSRP: $3618.62You Save: $1195.12 (34%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TURBOCHARGER SUB-ASS; Turbocharger

Toyota Turbocharger Assembly

Part Number: 17201-18030$3158.40 MSRP: $4715.93You Save: $1557.53 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TURBOCHARGER SUB-ASS; Turbocharger

Toyota Turbocharger Sub-Assy

Part Number: 17201-64010$781.94 MSRP: $1179.58You Save: $397.64 (34%)Ships in 1-3 Business DaysToyota Turbocharger Assembly

Part Number: 17201-F0010$2247.93 MSRP: $3356.46You Save: $1108.53 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TURBOCHARGER SUB-ASS

- Product Specifications

- Other Name: Turbocharger Sub-Assy; Turbocharger

- Product Specifications

- Other Name: Turbocharger Sub-Assy; Turbocharger

- Product Specifications

- Other Name: Turbocharger

- Product Specifications

- Other Name: Turbocharger Sub-Assy; Turbocharger

- Product Specifications

- Other Name: Turbocharger Sub-Assy; Turbocharger

- Product Specifications

- Other Name: Turbocharger Sub-Assy; Turbocharger

- Product Specifications

- Other Name: Turbocharger

- Product Specifications

- Other Name: Turbocharger

- Manufacturer Note: FR

- Position: Front

- Product Specifications

- Other Name: Turbocharger

- Manufacturer Note: RR

- Position: Rear

Toyota Turbocharger Parts Questions & Experts Answers

- Q: What are the key considerations for maintaining and diagnosing issues with a turbocharger on Toyota Supra?A:The turbocharger is basically a mechanically uncomplicated component; however, it is defined by its high precision and can be irreparably damaged by interrupted oil or coolant supply or loose or damaged ducts. Because it may take specialized tools and procedures, it is advisable to avail of a dealer service department to check and diagnose cases that may seem problematic, however, the home mechanic is capable of visually observing connections and linkages for tightness, signs of damage or other basic troubles. Both turbochargers make individual sounds, and a variation in the noise is considered unhealthy; for example, a high-pitched whistling sound implies a problem with the inlet air or exhaust gas leakage. When any strange noises are produced in vicinity to the turbine, the turbocharger is withdrawn for the inspection of the turbine wheel, all these procedures are to be done with the help of engine off and cool to avoid any hazards on individuals. The engine should not be running when attempting to turn the turbine wheel as an indication of a worn turbine bearing; the wheel should turn freely; if not, overheating can cause the cooling oil to sludge or coke. Also, the exhaust manifold should be inspected for crack and loose joints. Since the turbine wheel can turn up to 110 000 revolutions per minute, interruptions in the supply of coolant or loss of oil essentially result in critical damage and, therefore, one has to check for leaks of coolant and obstructions in the inlet of oil as well as in the oil drained back line due to massive loss of oil through turbocharger seals, apparent by burnt oil on the turbine housing. It is always necessary to flush the turbocharger with clean oil, any time that a major engine bearing is replaced.