My Garage

My Account

Cart

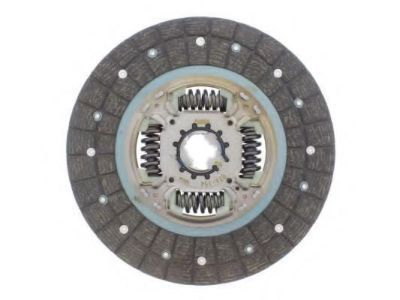

Genuine Toyota Solara Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Clutch Discs found

Toyota Solara Clutch Disc Assembly

Part Number: 31250-33040$116.69 MSRP: $164.48You Save: $47.79 (30%)Ships in 1-3 Business DaysToyota Solara Clutch Disc Assembly

Part Number: 31250-20141$61.67 MSRP: $87.11You Save: $25.44 (30%)Ships in 1-3 Business DaysToyota Solara Clutch Disc Assembly

Part Number: 31250-28181$215.86 MSRP: $309.53You Save: $93.67 (31%)Ships in 1-3 Business DaysToyota Solara Clutch Disc Assembly

Part Number: 31250-20250$122.02 MSRP: $173.47You Save: $51.45 (30%)Ships in 1-3 Business DaysToyota Solara Clutch Disc Assembly

Part Number: 31250-20251$122.02 MSRP: $173.47You Save: $51.45 (30%)Ships in 1-3 Business DaysToyota Solara Clutch Disc Assembly

Part Number: 31250-28180$215.86 MSRP: $309.53You Save: $93.67 (31%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-33090$54.62 MSRP: $76.34You Save: $21.72 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35667-33020$48.67 MSRP: $68.04You Save: $19.37 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-33100$49.62 MSRP: $69.36You Save: $19.74 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35667-06010$51.49 MSRP: $71.97You Save: $20.48 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-06010$55.32 MSRP: $77.32You Save: $22.00 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc Assembly

Part Number: 31250-33030$116.69 MSRP: $164.48You Save: $47.79 (30%)Ships in 1-3 Business DaysToyota Solara Clutch Disc Assembly

Part Number: 31250-33031$116.69 MSRP: $164.48You Save: $47.79 (30%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-33070$29.85 MSRP: $41.72You Save: $11.87 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-32050$37.76 MSRP: $52.78You Save: $15.02 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-21010$43.09 MSRP: $60.23You Save: $17.14 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-33050$46.01 MSRP: $64.30You Save: $18.29 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35667-08010$48.67 MSRP: $68.04You Save: $19.37 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35633-33030$49.62 MSRP: $69.36You Save: $19.74 (29%)Ships in 1-3 Business DaysToyota Solara Clutch Disc

Part Number: 35667-21010$51.49 MSRP: $71.97You Save: $20.48 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

Toyota Solara Clutch Disc

Toyota Solara vehicles depend on their Clutch Disc to join the engine to the transmission input shaft for seamless gear change operations. The Clutch Disc also has two friction materials that connect with both the pressure plate and flywheel to pass engine power between them. Gear changes become possible when driving the clutch pedal because this action separates the pressure plate from the Clutch Disc. When the driver releases the pedal the Toyota Clutch Disc establishes itself to enable power transfer. The Solara models employ organic and ceramic plates together with high-performance clutch plates such as kevlar and sintered iron for different driving purposes. Standard driving involves organic clutches and performance applications require ceramic clutches. Clutches featuring sprung hub designs include springs that minimize shocks and deliver smooth performance but racing needs rigid hub Toyota Clutch Discs. The Solara Clutch Disc's operation effectiveness diminishes because of wear and heat exposure which requires quick replacement to preserve vehicle performance.

If you are in demand for superior quality and affordable OEM Toyota Solara Clutch Disc, then shop with us! We own a wide range of the reduced-priced genuine Toyota Solara Clutch Disc. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Solara Clutch Disc Parts Questions & Experts Answers

- Q: How to remove and inspect Clutch Disc and Pressure Plate on 2002 through 2008 Toyota Solara?A:Engines are usually retained in the car and the transaxle is usually pulled to get access to the clutch components. In case the engine is pulled out for the major overhaul, it is recommended that the clutch should also be inspected for the worn out parts and replaced accordingly. Since getting to the clutch components is time consuming and may require a lot of effort, Singer suggests that during any engine or transaxle removal, the clutch components should be replaced although they are cheap. Specifically, the first thing to do is to take out the release cylinder but the hose attached must remain hanging arranged in a position that is out of the way. The transaxle has to be pulled out from the vehicle where the engine has to be properly supported perhaps with an engine hoist and one has to be much careful when removing the bolts on the oil pan. The release fork and bearing could still be permanently fixed on to the transaxle. There should be an alignment tool fitted through the clutch disc hub to help support the disc when it has to be removed. The flywheel and the pressure plate likewise should have their indexing marks checked; if none are present then new scribe marks should be made for use in aligning the two parts when re-fitting. The bolts that fasten pressure plate to the flywheel should be loosened in the cross-wise manner to allow spring tension be released before the pressure plate along with the clutch disc is removed. All other parts should also be checked for wear; flywheel for cracks and damages, clutch disc lining for thickness and any signs of damages, pressure plate for score marks and signs of overheating. This bearing should be also replaced along with the clutch disc as it will reach its wearing out point in the shortest time. Flies: before installed, the both surfaces of the flywheel and pressure plate must be free from oil and grease. Position clutch disc and pressure plate with the alignment tool to make sure that it is correctly placed. It is recommended that the pressure plate-to-flywheel bolts be tightened only until they are just barely snug in a manner that alternates between opposite bolts so that the flywheel doesn't get warped, then torqued to the correct amount. High-temperature grease should be applied to the inner groove of the Release Bearing and other contact part, then the release bearing should be placed in. Last but not least, the transaxle, release cylinder, and all the above-mentioned parts have to be refitted again and all fasteners have to be tightened to the specified torque.